Low-temperature high-strength oil-gas well plugging agent

A technology for oil and gas wells and plugging agents, applied in the field of oil and gas well sealing and plugging agents, low-temperature high-strength oil and gas well plugging agents, can solve the problems of slow development of low-temperature strength and weak impact resistance that cannot meet the construction requirements of channeling and plugging and other problems, to achieve the effect of excellent water impact resistance, rapid increase in strength, and increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

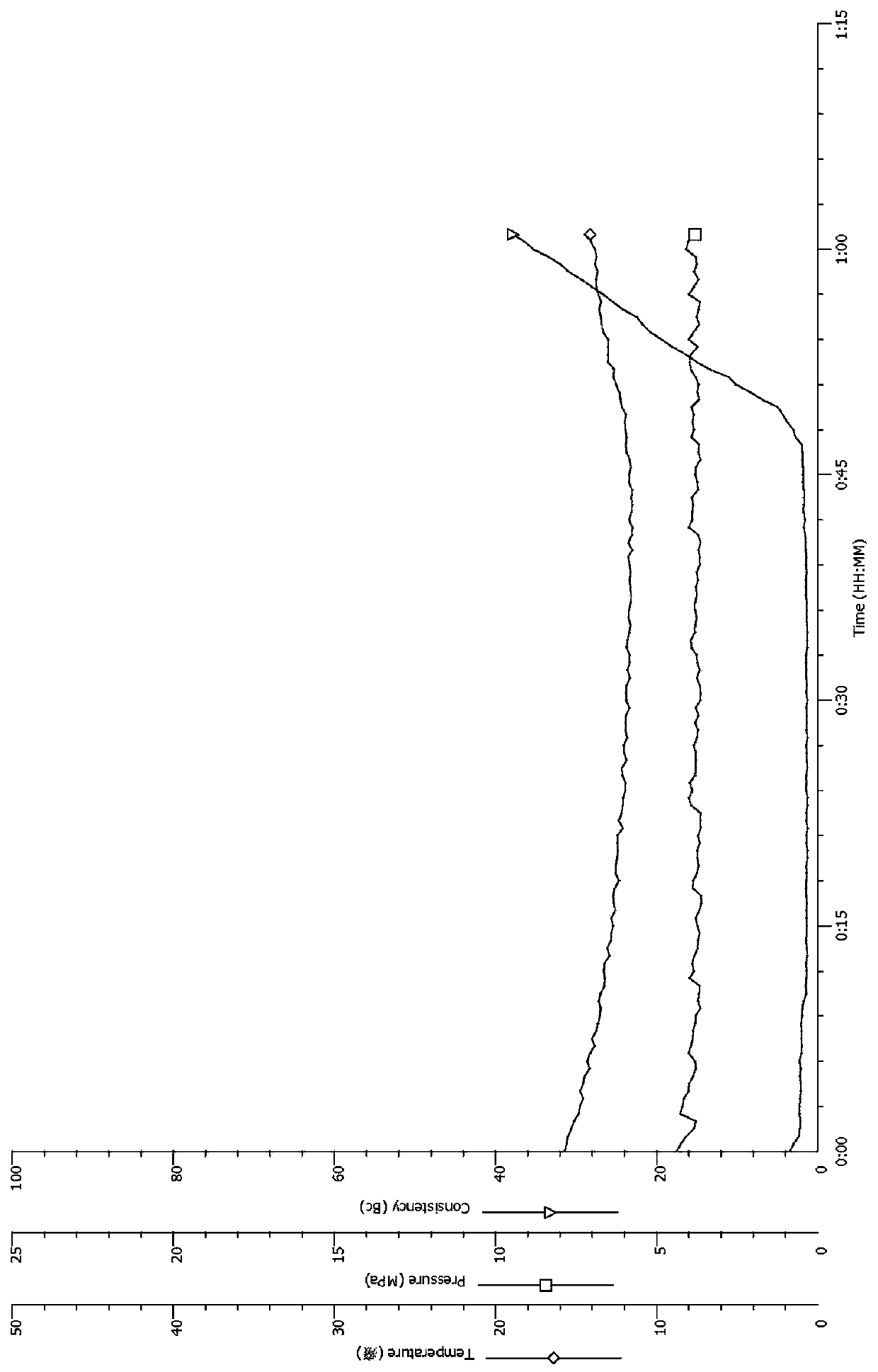

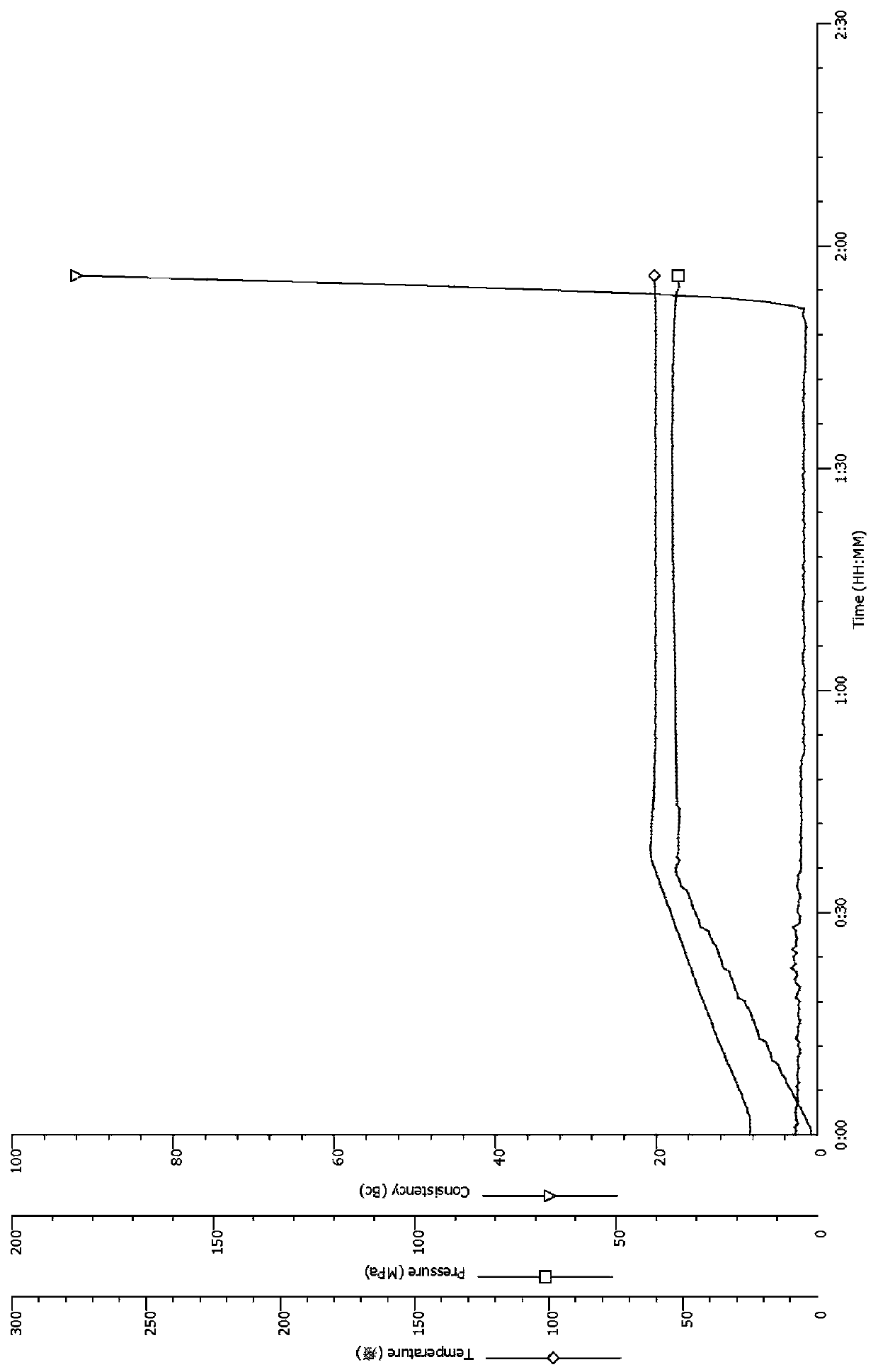

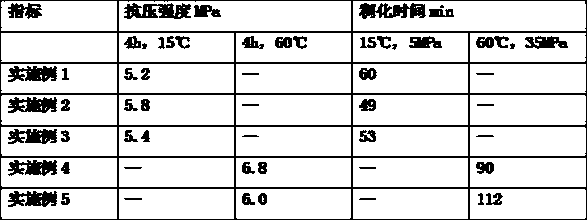

[0026] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0027] A low-temperature high-strength oil well plugging agent, including the following raw materials in terms of mass percentage: 80% sulfoaluminate cement, 0.1% basalt fiber, 0.1% hydroxypropyl methylcellulose ether, 0.1% polyacrylamide, calcium carbonate 18%, bentonite 1.6%, boric acid 0.05%, D-sodium gluconate 0.05%; the specific surface area of the described sulfoaluminate cement is 350cm 2 / g-450cm 2 / g; the fiber length of basalt fiber is less than 12cm; the specific surface area of calcium carbonate powder is greater than 800cm 2 / g.

Embodiment 2

[0029] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0030] A low-temperature high-strength oil well plugging agent, including the following raw materials in terms of mass percentage: 70% of sulfoaluminate cement, 0.2% of hydroxypropyl methylcellulose ether, 0.1% of polyacrylamide, 20% of calcium carbonate, and 9.65% of bentonite %, boric acid 0.02%, D-sodium gluconate 0.03%; the specific surface area of the described sulphoaluminate cement is 350cm 2 / g-450cm 2 / g; the fiber length of basalt fiber is less than 12cm; the specific surface area of calcium carbonate powder is greater than 800cm 2 / g.

Embodiment 3

[0032]As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0033] A low-temperature high-strength oil well plugging agent, including the following raw materials in terms of mass percentage: 90% sulfoaluminate cement, 0.3% basalt fiber, 0.25% hydroxypropyl methylcellulose ether, 4.33% calcium carbonate, and 5% bentonite , boric acid 0.02%, D-sodium gluconate 0.1%; the specific surface area of the described sulfoaluminate cement is 350cm 2 / g-450cm 2 / g; the fiber length of basalt fiber is less than 12cm; the specific surface area of calcium carbonate powder is greater than 800cm 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com