Self-resetting anti-seismic energy dissipation split column

A self-resetting and splitting technology, used in earthquake prevention, water conservancy projects, artificial islands, etc., can solve problems such as damage, destruction of underground structural systems, and reduction of shear strength and ultimate deformation capacity, to reduce damage, improve ductility, and ensure The effect of safety features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

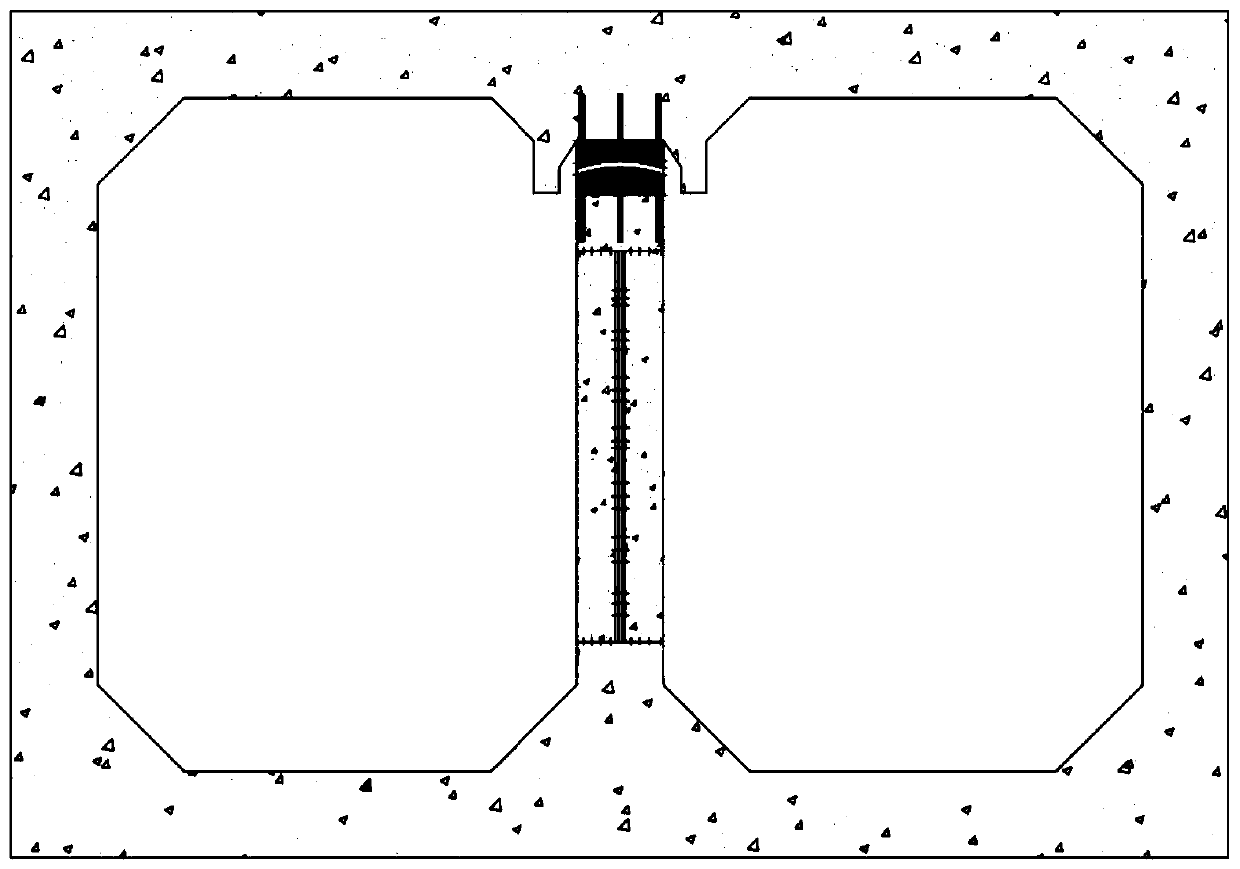

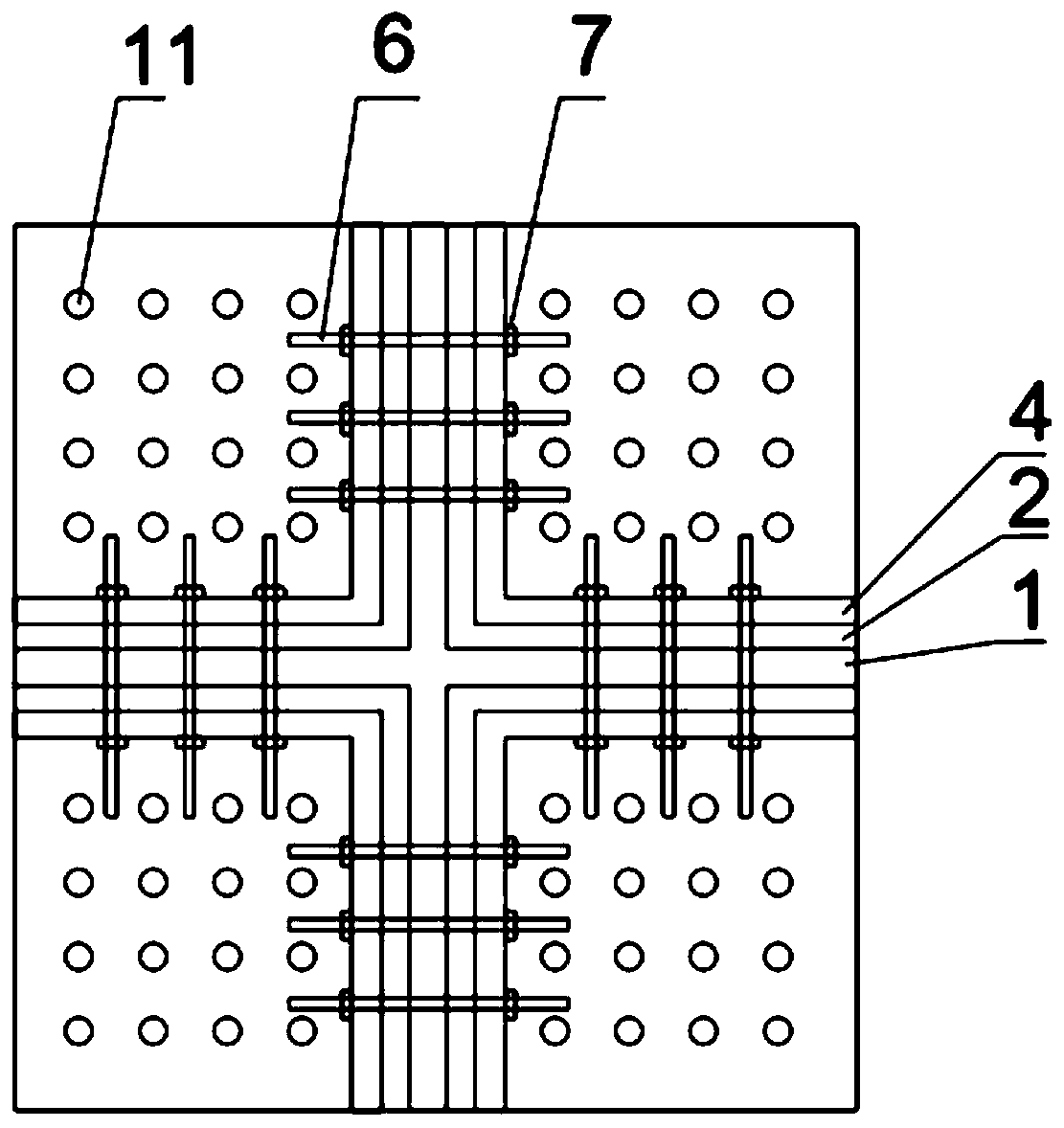

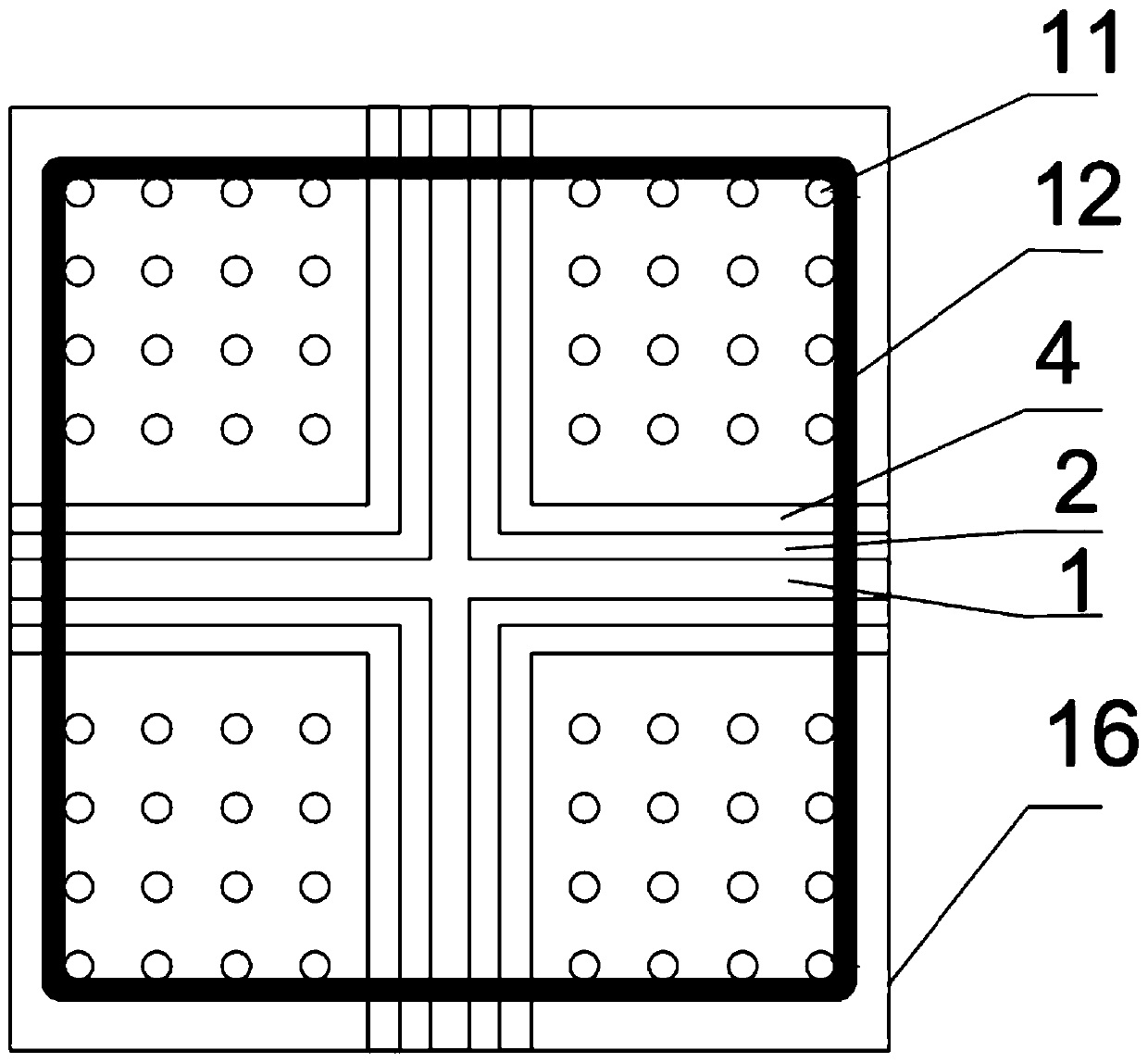

[0035] refer to Figure 1-9 , a self-resetting anti-seismic energy-dissipating split column, including a sliding concrete column, and a prefabricated sliding main board 1 inside it;

[0036] The sliding main board 1 includes a plurality of vertical and circumferentially arranged sliders, the ends of the plurality of sliders located at the center of the circle are fixed to each other, a concrete column is arranged in the area between two adjacent sliders, and a friction plate is arranged between the sliders and the concrete columns 2 and the sub-plate 4, the friction plate 2 is located between the sub-plate 4 and the slide plate, the slide plate, the friction plate 2 and the sub-plate 4 can slide each other, the sliding main board 1 and the friction plate 2 are located on the sub-plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com