Photoelectric module assembly with constant temperature control function and manufacturing method thereof

A photoelectric module and constant temperature control technology, applied in the direction of electrical components, electric solid-state devices, laser components, etc., can solve problems such as large volume, poor process quality consistency, insensitive temperature control, etc., and achieve high-sensitivity temperature control and accurate solution The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

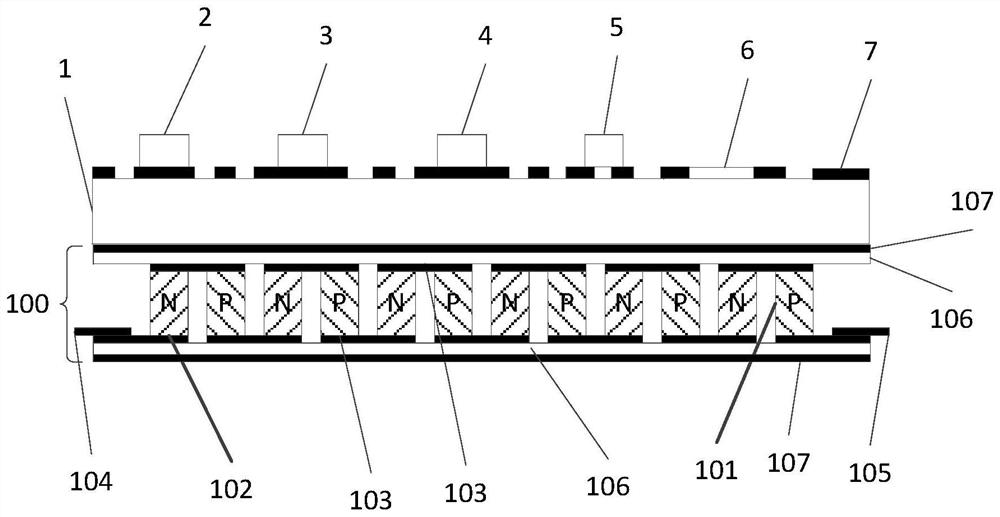

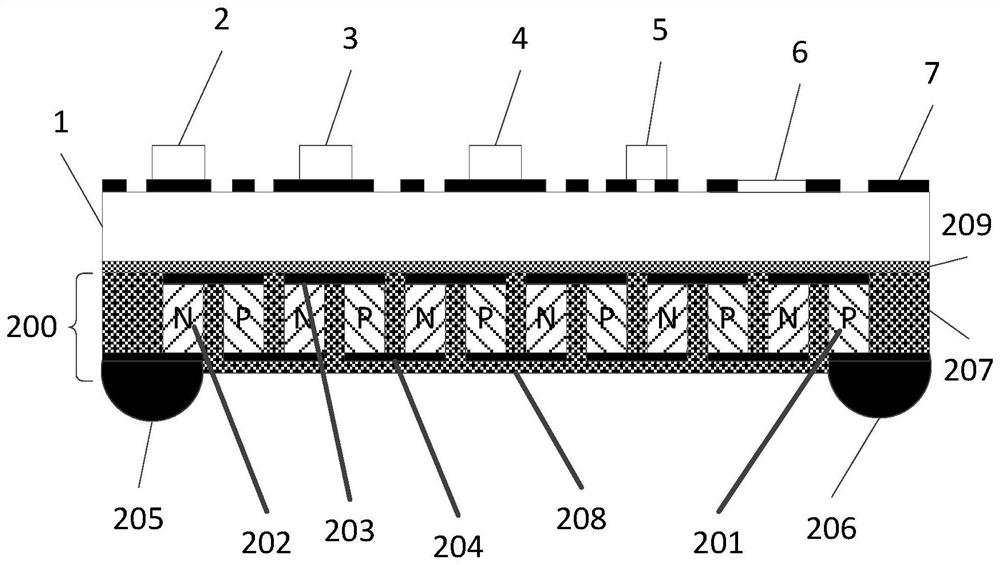

[0056] 1. A photoelectric module assembly with a constant temperature control function, the integrated TEC p-type semiconductor (201) adopts a p-type bismuth telluride semiconductor material, and the p-type bismuth telluride semiconductor material is Bi 2 Te 3 -Sb 2 Te 3 , the thickness of the integrated TEC p-type semiconductor (201) is 0.2mm-0.6mm.

[0057] The integrated TEC n-type semiconductor (202) adopts n-type bismuth telluride semiconductor material, and the n-type bismuth telluride semiconductor material is Bi 2 Te 3 -Bi 2 Se 3 , the thickness of the integrated TEC n-type semiconductor (202) is 0.2mm-0.6mm.

[0058] 2. A photoelectric module assembly with constant temperature control function, the material of the integrated TEC top metal electrode (203) and the integrated TEC bottom metal electrode (204) is a nickel-chromium-copper-nickel-chromium-gold composite conductor.

[0059] 3. A photoelectric module assembly with constant temperature control function, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com