Preparation process of light fiber reinforced thermoplastic plate for shielding curtain

A technology that enhances thermoplastic and lightweight fibers. It is applied in applications, flat products, household appliances, etc., and can solve the problems of increasing the production cycle of blinds, energy consumption and production costs, limiting production speed, and shortening the production cycle of blinds. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

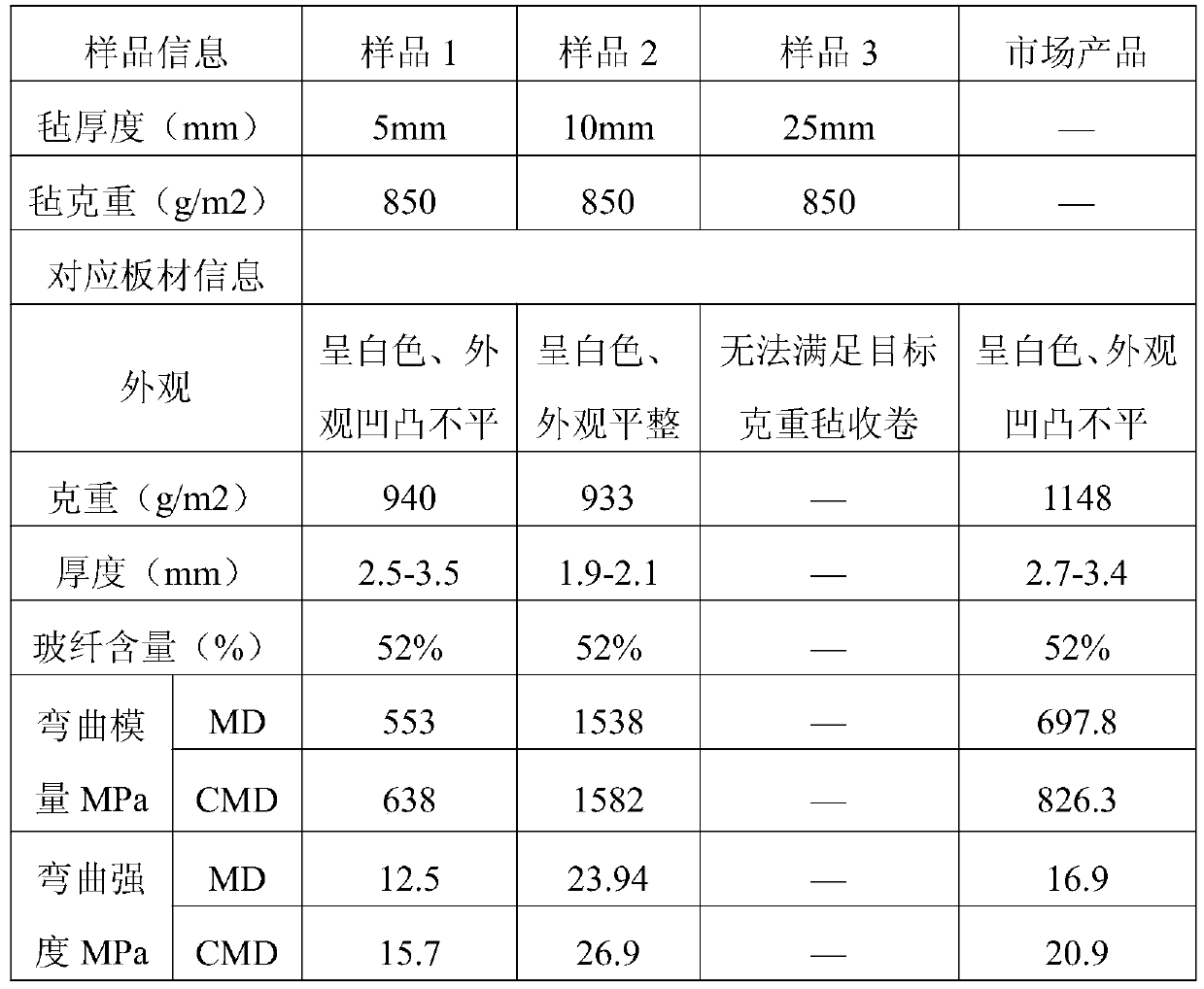

[0029] This implementation is a preparation process of lightweight fiber-reinforced thermoplastic sheets for shade curtains. The sheet structure from top to bottom is modified PET fabric, modified PA film, fiber-reinforced thermoplastic resin felt, modified PP film and Modified PA fabric.

[0030] The fiber-reinforced thermoplastic resin mat includes thermoplastic resin fibers and reinforcing fibers, the thermoplastic resin fibers are modified polypropylene fibers PP, and the addition amount is 48wt%; the reinforcement fibers are modified glass fibers, and the addition amount is 52wt%.

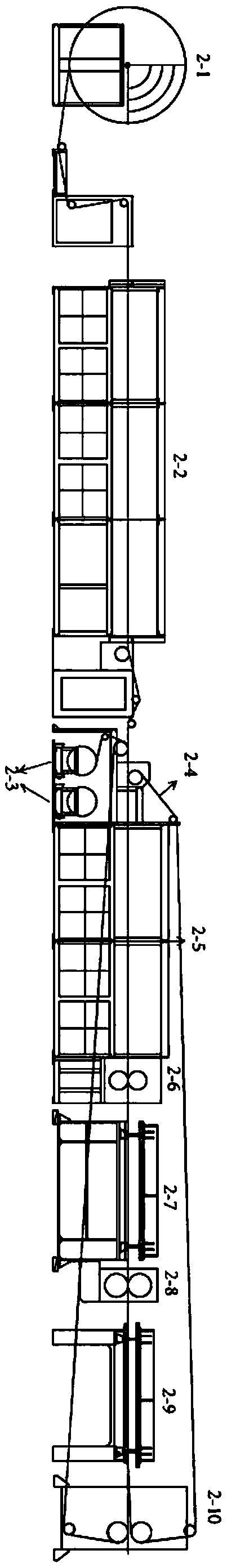

[0031] Its preparation method adopts continuous rolling, hot plate and cold plate combination process, and the specific steps are as follows:

[0032] (1) Fabrication of fiber-reinforced thermoplastic resin felt: after the modified polypropylene fiber with a mass fraction of 48% and the modified glass fiber with a mass fraction of 52% are loosened and mixed evenly by an opener, the net is laid...

Embodiment 2

[0042] This implementation is a preparation process of lightweight fiber-reinforced thermoplastic sheets for shade curtains. The sheet structure from top to bottom is modified PET fabric, modified PA film, fiber-reinforced thermoplastic resin felt, modified PP film and Modified PA fabric.

[0043] The fiber-reinforced thermoplastic resin mat includes thermoplastic resin fibers and reinforcing fibers, the thermoplastic resin fibers are modified polypropylene fibers PP, and the addition amounts are 65%, 48wt%, and 40% respectively; the reinforcement fibers are modified glass fibers, and the addition amounts are 35% %, 52wt%, 60%.

[0044] Its preparation method adopts continuous rolling, hot plate and cold plate combination process, and the specific steps are as follows:

[0045] (1) Fiber-reinforced thermoplastic resin felt: the modified polypropylene fibers with mass fractions of 65%, 48wt%, and 40%, and the corresponding modified glass fibers of 35%, 52wt%, and 60% are loose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com