Preparation method of heterogeneous layered aluminum-based composite material

An aluminum-matrix composite material and an aluminum-matrix composite technology, applied in the field of preparation of heterogeneous layered aluminum-matrix composite materials, can solve the problems of limited strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

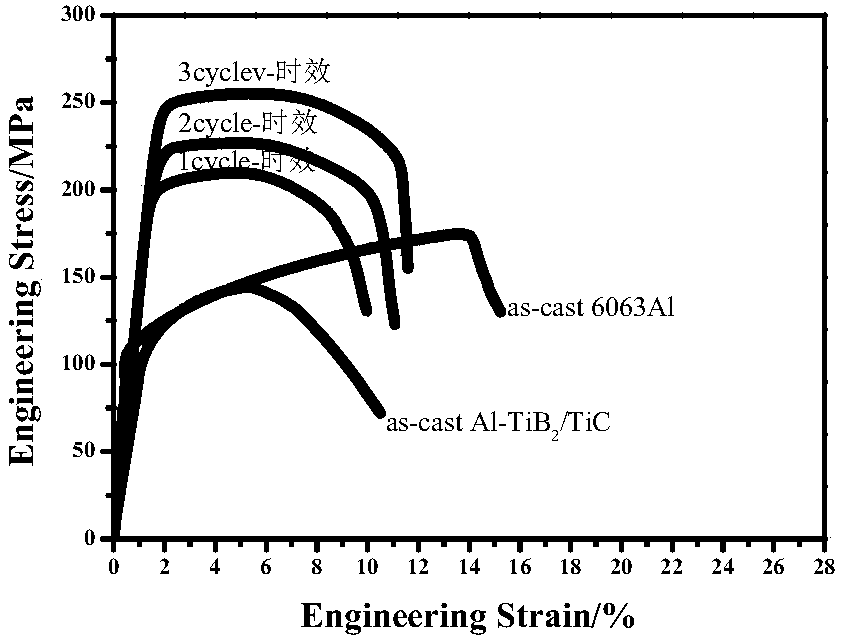

Embodiment 1

[0035] Preparation of Heterogeneous Layered 6063Al / Al-TiB 2 The method for / TiC aluminum matrix composite material, comprises the following steps:

[0036] (1) Cast Al-TiB 2 / TiC and 6063Al ingots were cut into regular plates with length, width and height of 50×26×2 mm, respectively.

[0037] (2) Put the cut sheet into a box-type resistance furnace at a temperature of 530° C. and keep it warm for 2 hours for solution treatment.

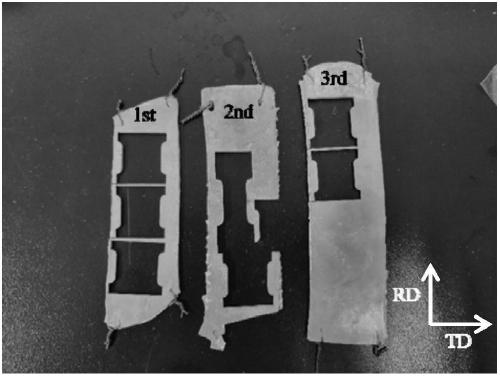

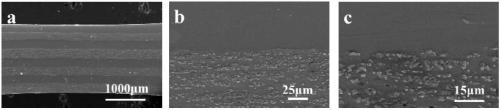

[0038] (3) Steel wire brush and abrasive paper are used to mechanically clean the plate after solid solution treatment, and then the cleaning of the surface oxide layer is carried out with alcohol; the Al-TiB after cleaning 2 / TiC and 6063Al sheet stacking, according to Al-TiB 2 / TiC sheets and 6063Al sheets are stacked to two layers in sequence, and the four corners of the plates are bound and fixed with iron wires.

[0039] (4) 530° C. heat preservation for 10 minutes, and then rolling, with a rolling reduction of 50%. 6063Al / Al-TiB obtained a...

Embodiment 2

[0042] Preparation of Heterogeneous Layered 6063Al / Al-TiB 2 The method for / TiC aluminum matrix composite material, comprises the following steps:

[0043] (1) Cast Al-TiB 2 / TiC and 6063Al ingots were cut into regular plates with length, width and height of 50×26×2 mm, respectively.

[0044] (2) Put the cut sheet into a box-type resistance furnace at a temperature of 530° C. and keep it warm for 2 hours for solution treatment.

[0045] (3) Steel wire brush and abrasive paper are used to mechanically clean the plate after solid solution treatment, and then the cleaning of the surface oxide layer is carried out with alcohol; the Al-TiB after cleaning 2 / TiC and 6063Al plates, according to Al-TiB 2 / TiC sheets and 6063Al sheets are stacked to two layers in sequence, and the four corners of the plates are bound and fixed with iron wires.

[0046] (4) 530° C. heat preservation for 10 minutes, and then rolling, with a rolling reduction of 50%.

[0047](5) The rolled and welde...

Embodiment 3

[0052] Preparation of Heterogeneous Layered 6063Al / Al-TiB 2 The method for / TiC aluminum matrix composite material, comprises the following steps:

[0053] (1) Cast Al-TiB 2 / TiC and 6063Al ingots were cut into regular plates with length, width and height of 50×26×2 mm, respectively.

[0054] (2) Put the cut sheet into a box-type resistance furnace at a temperature of 530° C. and keep it warm for 2 hours for solution treatment.

[0055] (3) Steel wire brush and abrasive paper are used to mechanically clean the plate after solid solution treatment, and then the cleaning of the surface oxide layer is carried out with alcohol; the Al-TiB after cleaning 2 / TiC and 6063Al plates, according to Al-TiB 2 / TiC sheets and 6063Al sheets are stacked to two layers in sequence, and the four corners of the plates are bound and fixed with iron wires.

[0056] (4) 530° C. heat preservation for 10 minutes, and then rolling, with a rolling reduction of 50%.

[0057] (5) The rolled and weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com