Nitrogen-doped carbon nanomaterial and preparation method thereof

A technology of nitrogen-doped carbon and nanomaterials, applied in the direction of nano-carbon, etc., can solve the problems of increased preparation cost, expensive operation process and multi-step purification process, etc., and achieve the effect of rich performance, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

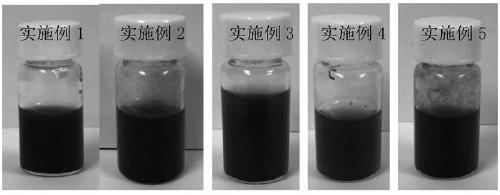

Embodiment 1

[0030] Take by weighing 1.37g zinc gluconate (monomer zinc gluconate, molecular formula C 12 h 22 o 14 Zn, the same below; 3mmol), 0.58g citric acid (3mmol) were added in the polytetrafluoroethylene reaction tank, then added 70mL formamide / ammonia mixed solution (mass fraction 25% ammonia water / formamide volume ratio is 3 / 2) , placed on a magnetic stirrer, and stirred at a speed of 290 r / min to completely dissolve the solid and mix evenly. The obtained reaction system was placed in a microwave synthesizer, and the temperature was raised to 160°C at a rate of 8°C / min for reaction. After 1.5 hours of reaction, the system temperature automatically dropped to room temperature, and the obtained reaction product was filtered by vacuum filtration. Then the black solid was washed with pure water until the filtrate was colorless; the obtained black solid was dried in a vacuum oven at 90° C. for 5 h to obtain a nitrogen-doped carbon nanomaterial.

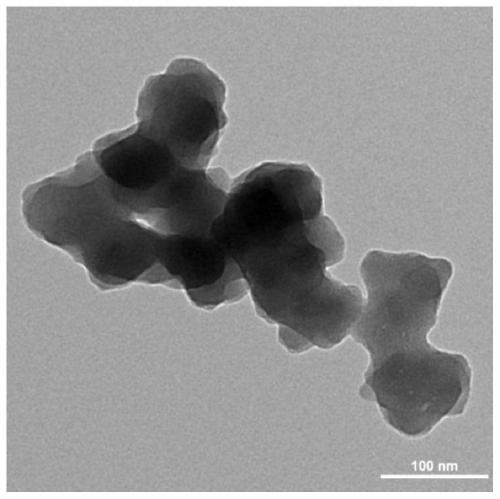

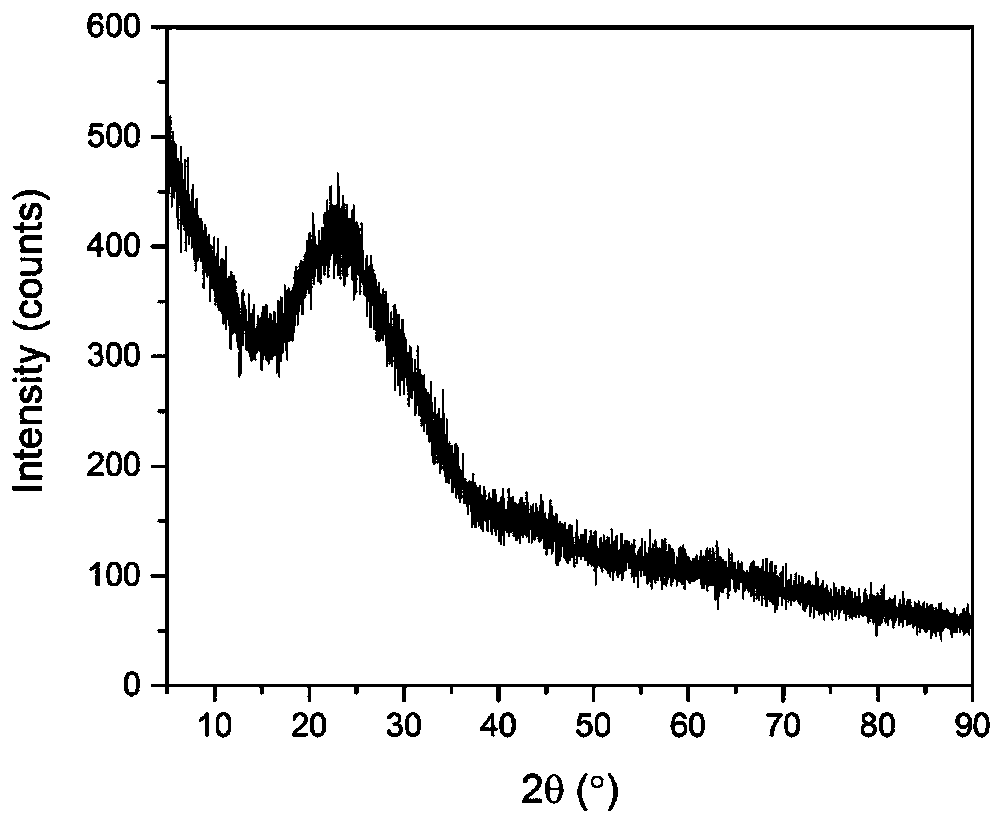

[0031] The obtained nitrogen-doped ...

Embodiment 2

[0036]Weigh 1.82g of zinc gluconate (4mmol) and 0.38g of citric acid (2mmol) into a polytetrafluoroethylene reaction tank, then add 50mL of N,N-dimethylformamide (DMF), and place in a magnetic stirrer On, stir at 350r / min to dissolve the solid completely and mix evenly. The obtained reaction system was placed in a microwave synthesizer, and the temperature was raised to 180°C at a rate of 9°C / min for reaction. After 3 hours of reaction, the system temperature automatically dropped to room temperature, and the obtained reaction product was filtered by vacuum filtration, and then The black solid was washed with pure water until the filtrate was colorless; the obtained black solid was dried in a vacuum oven at 80° C. for 10 h to obtain a nitrogen-doped carbon nanomaterial.

Embodiment 3

[0038] Weigh 0.46g of zinc gluconate (1mmol) and 0.38g of citric acid (2mmol) into a polytetrafluoroethylene reaction tank, then add 66mL of 15% ammonia water in mass fraction, place on a magnetic stirrer, and use 200r / min rotating speed Stir to completely dissolve the solids and mix well. The obtained reaction system was placed in a microwave synthesizer, and the temperature was raised to 140°C at a rate of 7°C / min for reaction. After 6 hours of reaction, the system temperature automatically dropped to room temperature, and the obtained reaction product was filtered by vacuum filtration, and then The black solid was washed with pure water until the filtrate was colorless; the obtained black solid was dried in a vacuum oven at 60° C. for 12 hours to obtain a nitrogen-doped carbon nanomaterial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com