Solid waste-based porous sewage treatment agent as well as preparation method and application thereof

A sewage treatment agent and pure water technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of single sewage treatment index, single utilization object, and low utilization rate of solid waste To achieve the effect of rich internal pores, uniform pores and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

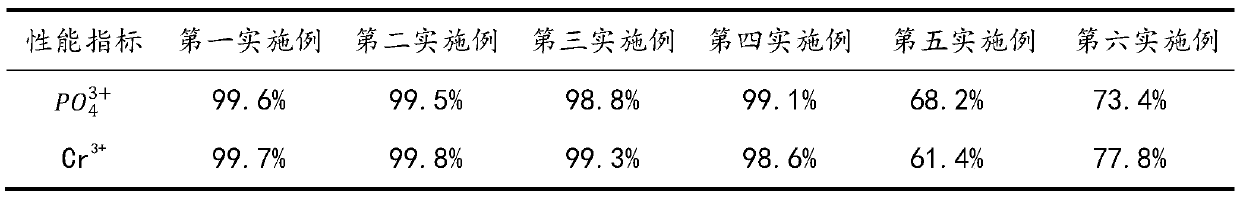

Examples

no. 1 example

[0041] A kind of preparation of solid waste base porous sewage treatment agent, comprises the steps:

[0042] (1) In parts by weight, the raw materials shown in Table 1 are weighed.

[0043] Table 1

[0044] components red mud mineral powder fly ash steel slag Zeolite Compound blowing agent sodium hydroxide Magnesium Aluminum Silicate water content 40 40 20 20 9 8 6 6 52

[0045] (2) Put the red mud, mineral powder, fly ash and steel slag in Table 1 into the forced mixer and stir for 30 minutes, then pour the compound foaming agent, sodium hydroxide, magnesium aluminum silicate and water, and stir evenly pouring the obtained slurry into a spherical mould, and drying after demolding to obtain a spherical porous sewage treatment agent.

no. 2 example

[0047] A kind of preparation of solid waste base porous sewage treatment agent, comprises the steps:

[0048] (1) In parts by weight, the raw materials shown in Table 2 are weighed.

[0049] Table 2

[0050] components red mud mineral powder fly ash steel slag Zeolite Compound blowing agent Sodium silicate polyvinyl alcohol water content 60 30 20 30 10 8 6 8 60

[0051] (2) Put the red mud, slag, fly ash and steel slag in Table 2 into the forced mixer and stir for 30 minutes, then pour the composite foaming agent, sodium hydroxide, magnesium aluminum silicate and water, and stir evenly pouring the obtained slurry into a spherical mould, and drying after demolding to obtain a spherical porous sewage treatment agent.

no. 3 example

[0053] A kind of preparation of solid waste base porous sewage treatment agent, comprises the steps:

[0054] (1) In parts by weight, the raw materials shown in Table 3 are weighed.

[0055] table 3

[0056] components red mud mineral powder fly ash steel slag Zeolite Compound blowing agent sodium bicarbonate Sodium bentonite water content 20 30 10 15 8 7 4 6 35

[0057] (2) Put the red mud, mineral powder, fly ash and steel slag in Table 3 into the forced mixer and stir for 25 minutes, then pour the compound foaming agent, sodium hydroxide, magnesium aluminum silicate and water, and stir evenly pouring the obtained slurry into a spherical mould, and drying after demolding to obtain a spherical porous sewage treatment agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com