A pd/ag/sio 2 Preparation method of composite membrane

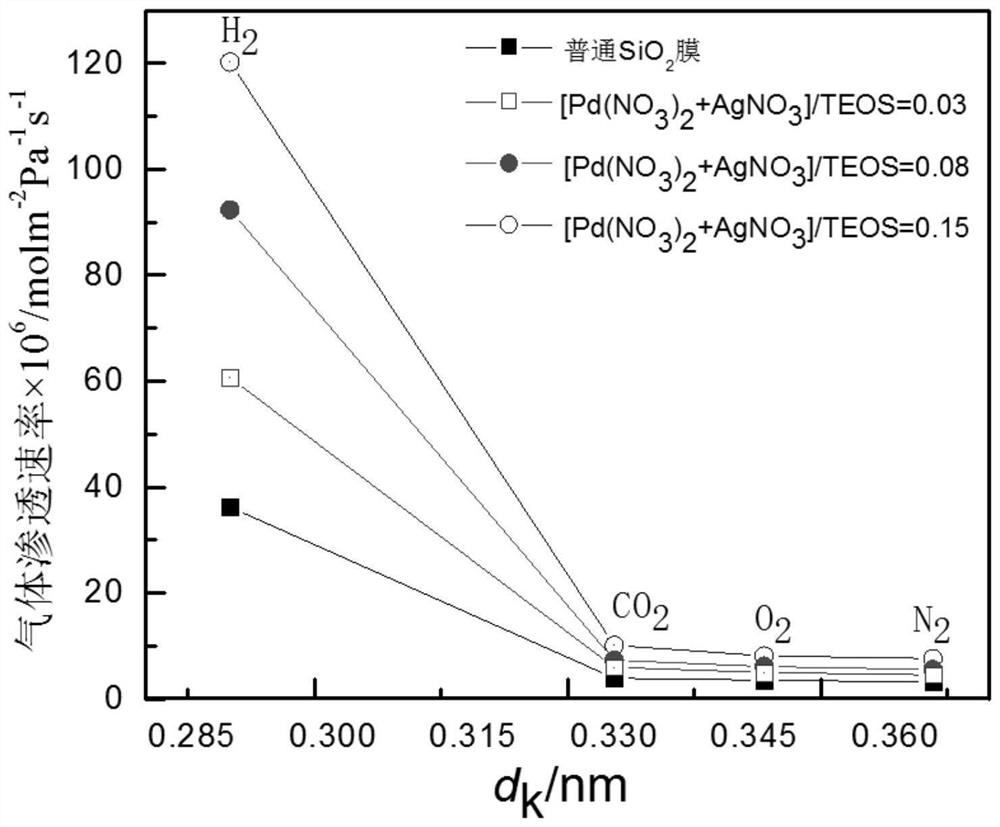

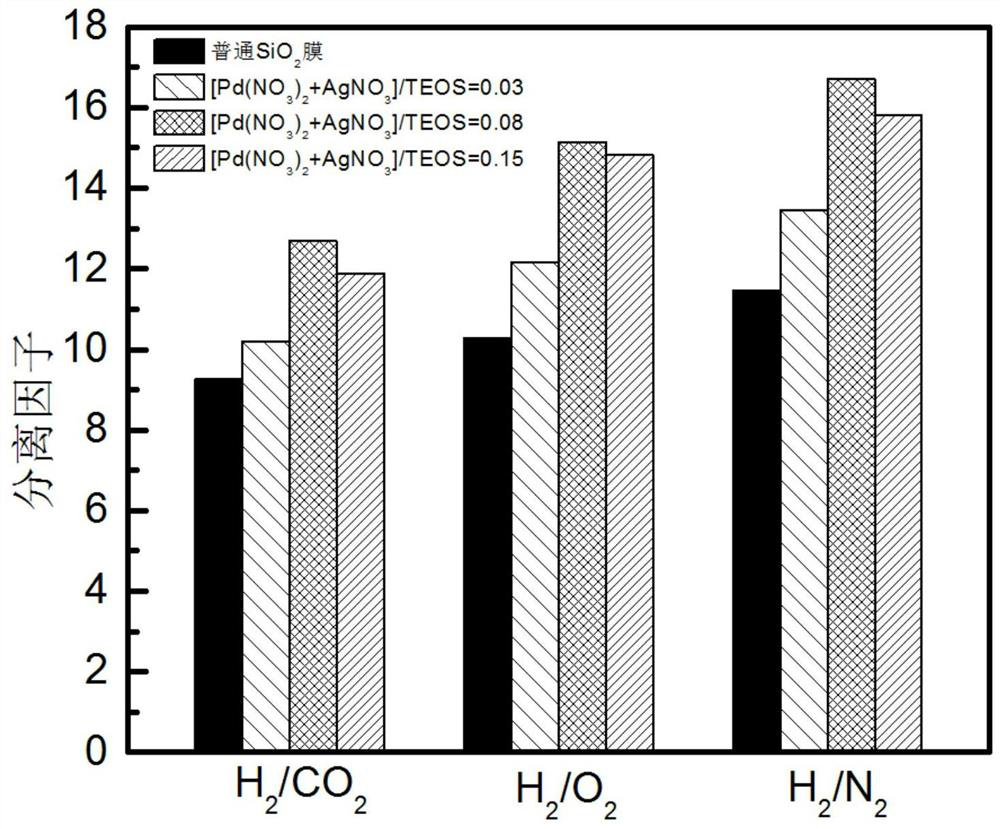

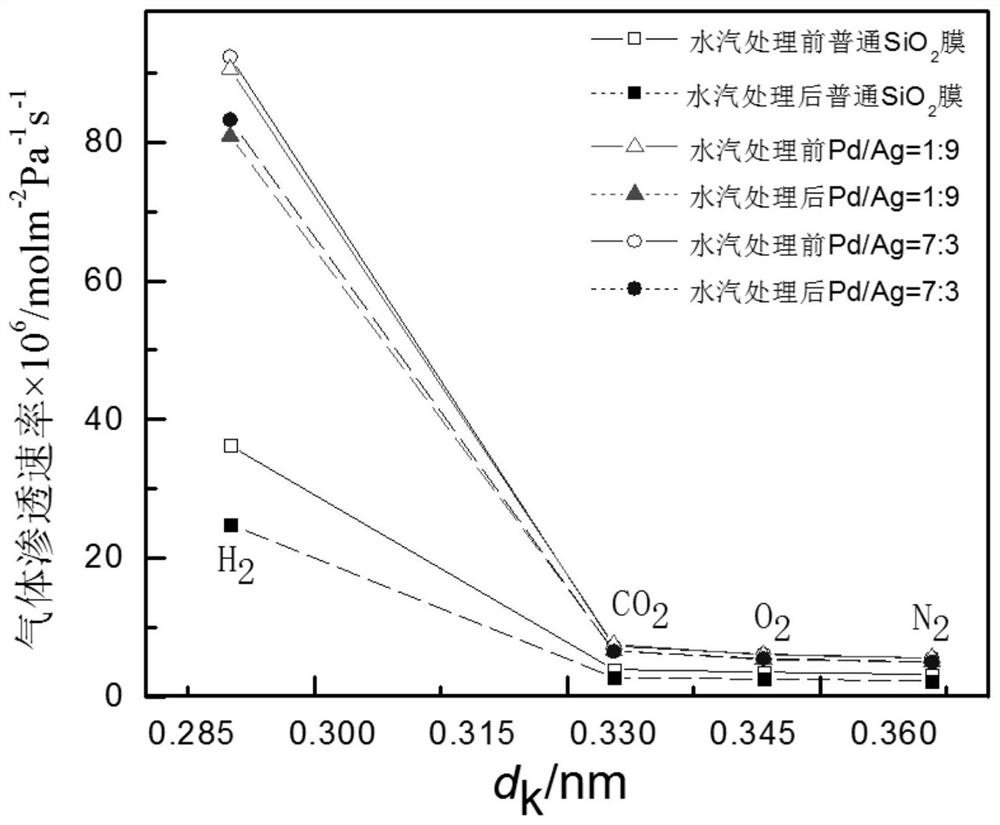

A composite membrane and mixed liquid technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of water vapor stability, gas permeation rate and separation factor that are difficult to improve at the same time, so as to improve H2 separation selectivity, Effect of preventing hydrogen embrittlement and increasing penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A Pd / Ag / SiO 2 The preparation method of composite film is specifically implemented according to the following steps:

[0062] Step 1, to the HNO of 3mol / L 3 Pd(NO 3 ) 2 2H 2 O, stirred vigorously at 20°C for 8 hours to fully dissolve and obtain 0.6mol / L Pd(NO 3 ) 2 2H 2 O solution;

[0063] Step 2, prepare 1mol / L AgNO 3 solution;

[0064] Step 3: Thoroughly mix ethyl orthosilicate (TEOS), absolute ethanol (EtOH), and N,N-dimethylformamide (DMF) into a homogeneous solution, place it in an ice-water mixture, and add it while stirring Water and HNO at a concentration of 1.5mol / L 3 The mixture was stirred and refluxed at 50 ° C for 5 h and then cooled to obtain SiO 2 Sol; Among them, tetraethyl orthosilicate (TEOS), absolute ethanol (EtOH), water, N, N-dimethylformamide (DMF), HNO 3 The molar ratio is 1:3.5:4:1.5:0.04;

[0065] Step 4, to the SiO obtained in step 3 2 Pd(NO 3 ) 2 2H 2 O, AgNO 3 solution and ethanol mixture (Pd(NO 3 ) 2 2H 2 O, AgNO 3 Th...

Embodiment 2

[0069] A Pd / Ag / SiO 2 The preparation method of composite film is specifically implemented according to the following steps:

[0070] Step 1, to the HNO of 3.5mol / L 3 Pd(NO 3 ) 2 2H 2 O, stirred vigorously at 40°C for 5h to fully dissolve and obtain 0.75mol / L of Pd(NO 3 ) 2 2H 2 O solution;

[0071] Step 2, prepare 1.3mol / L AgNO 3 solution;

[0072] Step 3: Thoroughly mix tetraethyl orthosilicate (TEOS), absolute ethanol (EtOH), and N,N-dimethylformamide (DMF) into a homogeneous solution, place it in an ice-water mixture, and add it while stirring Water and HNO at a concentration of 2.0mol / L 3 The mixture was stirred and refluxed at 65 ° C for 3 h and then cooled to obtain SiO 2 Sol; Among them, tetraethyl orthosilicate (TEOS), absolute ethanol (EtOH), water, N, N-dimethylformamide (DMF), HNO 3 The molar ratio is 1:7:6:2.25:0.07;

[0073] Step 4, to the SiO obtained in step 3 2 Pd(NO 3 ) 2 2H 2 O, AgNO 3 solution and ethanol mixture (Pd(NO 3 ) 2 2H 2 O, AgN...

Embodiment 3

[0077] A kind of Pd / Ag / SiO The preparation method of composite membrane, specifically implement according to the following steps:

[0078] Step 1, to the HNO of 3.8mol / L 3 Pd(NO 3 ) 2 2H 2 O, stirred vigorously at 60°C for 2h to fully dissolve to obtain 0.9mol / L Pd(NO 3 ) 2 2H 2 O solution;

[0079] Step 2, prepare 1.5mol / L AgNO 3 solution;

[0080] Step 3: Thoroughly mix tetraethyl orthosilicate (TEOS), absolute ethanol (EtOH), and N,N-dimethylformamide (DMF) into a homogeneous solution, place it in an ice-water mixture, and add it while stirring Water and HNO at a concentration of 2.0mol / L 3 The mixture was stirred and refluxed at 75°C for 2h and then cooled to obtain SiO 2 Sol; Among them, tetraethyl orthosilicate (TEOS), absolute ethanol (EtOH), water, N, N-dimethylformamide (DMF), HNO 3 The molar ratio is 1:10:8.0:3:0.10;

[0081] Step 4, to the SiO obtained in step 3 2 Pd(NO 3 ) 2 2H 2 O, AgNO 3 solution and ethanol mixture (Pd(NO 3 ) 2 2H 2 O, AgNO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com