Water-based color paste raw material treatment device

A technology of raw material processing and water-based color paste, which is applied in the direction of pigment slurry, solid separation, chemical instruments and methods, etc., can solve the problems of color paste color impurity, color paste color fading, and unrecoverable output, etc., to avoid color Effects of lightening, reducing iron black content, and eliminating magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

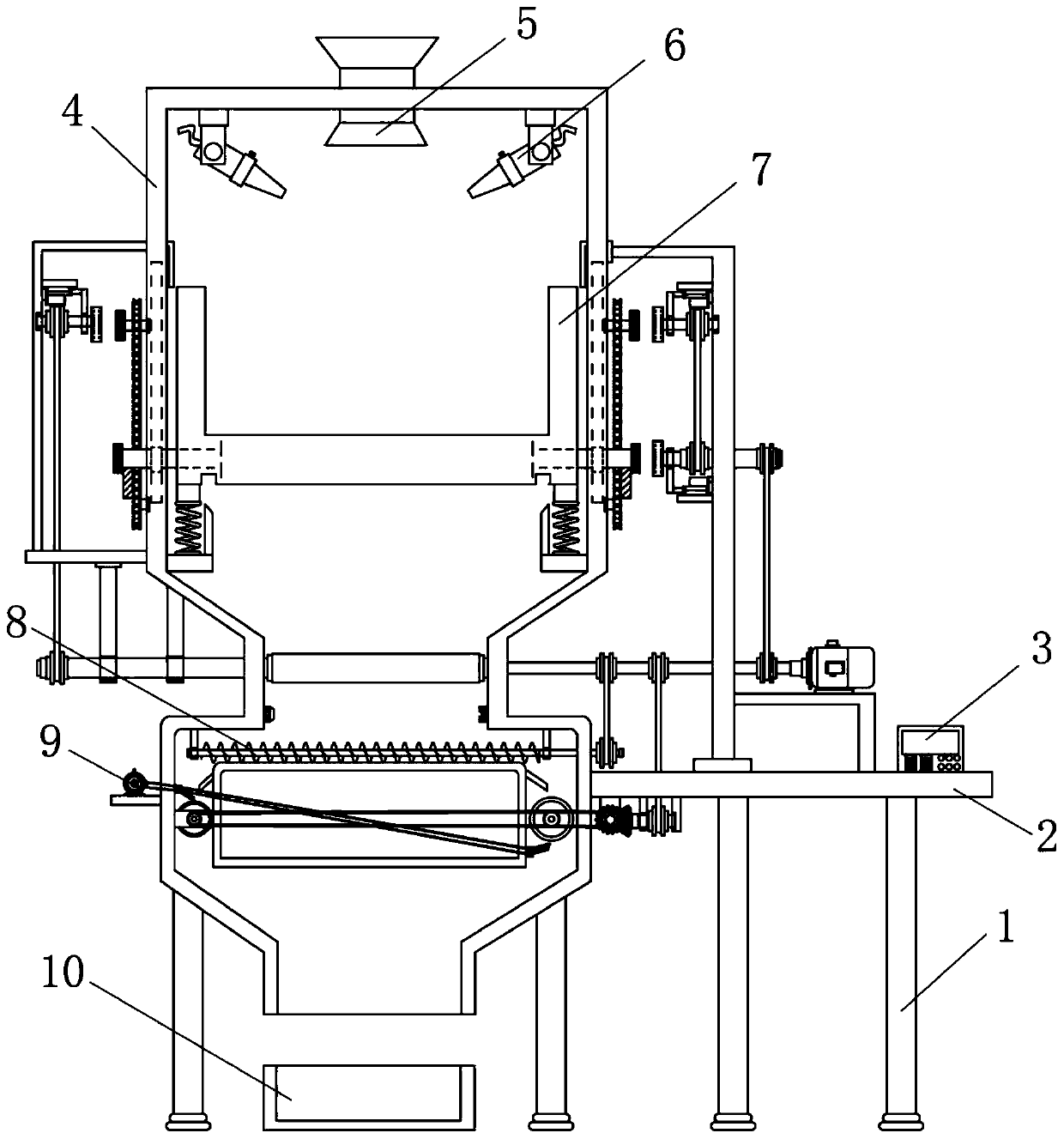

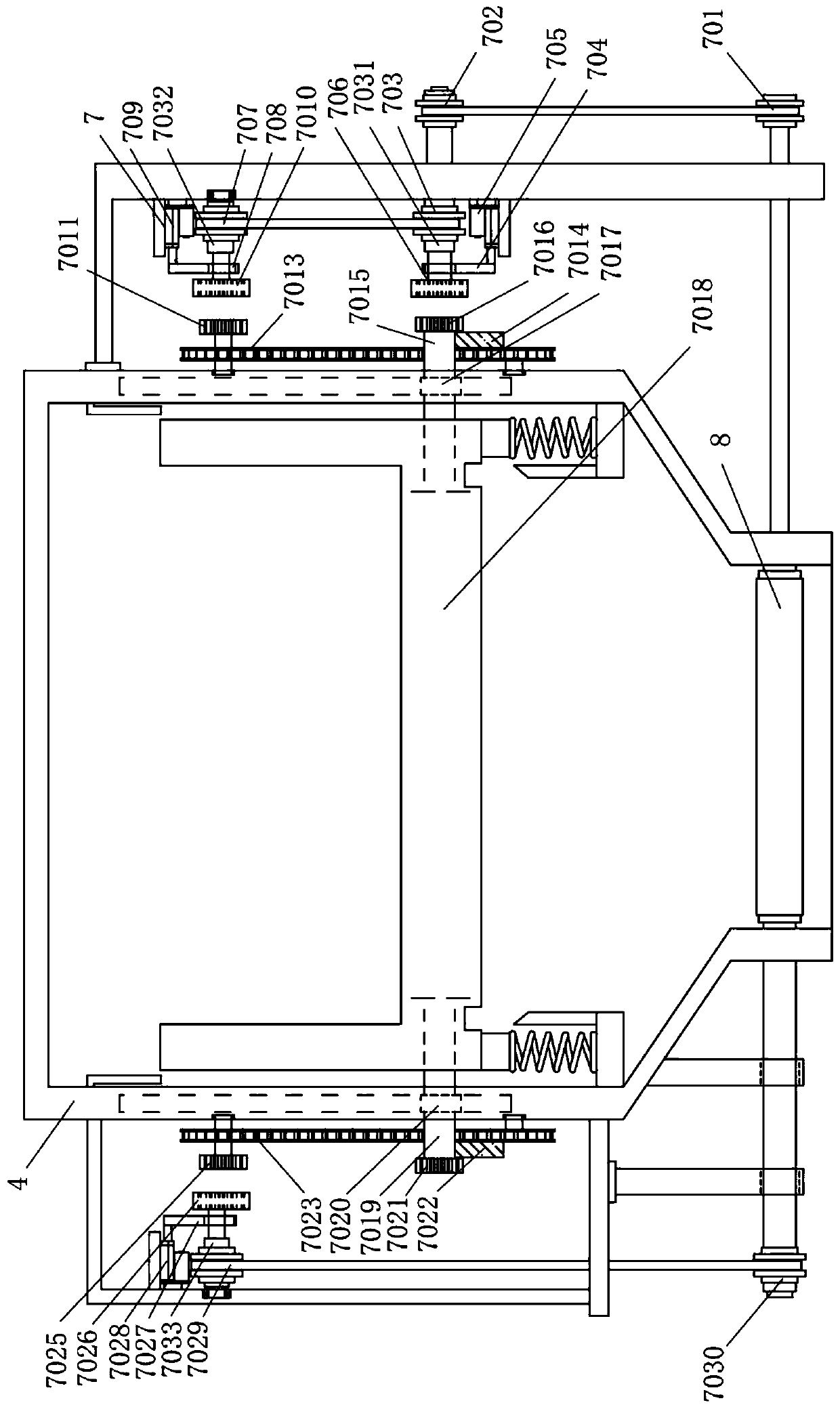

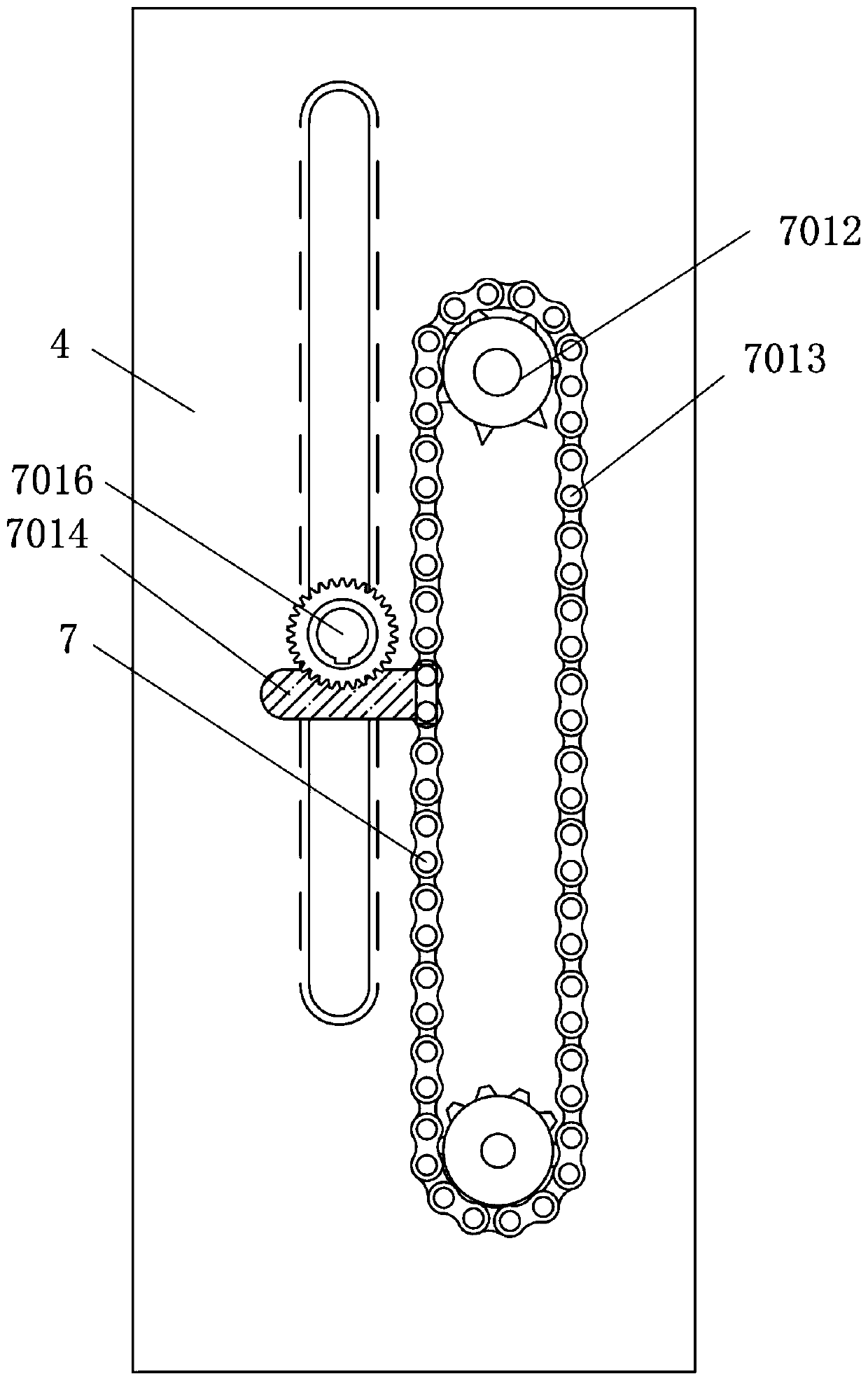

[0030] A water-based color paste raw material processing device, such as Figure 1-7 As shown, it includes foot 1, placing platform 2, control panel 3, processing box 4, material inlet 5, hot air nozzle 6, drying device 7, sorting device 8, degaussing recovery device 9 and collection box 10; the top of foot 1 Welding with the placing platform 2; the right side of the top of the placing platform 2 is connected with the control panel 3; the left end of the placing platform 2 is welded with the processing box 4; the top middle of the processing box 4 is sleeved with the inlet 5; the processing box 4 The right side of the inner top is bolted to the hot air nozzle 6; the top of the processing box 4 is provided with a drying device 7; the middle of the processing box 4 is provided with a sorting device 8, and the top right and left top of the sorting device 8 They are all connected to a drying device 7; a degaussing recovery device 9 is provided at the bottom of the processing box 4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com