Heat dissipation type conductive double-sided adhesive tape and production process thereof

A conductive double-sided adhesive and heat-dissipating technology, which is applied in the direction of conductive adhesives, adhesives, film/sheet adhesives, etc., can solve the problem of low heat dissipation at the joint of conductive double-sided adhesive, and achieve good Thermal conductivity and heat dissipation efficiency, improve heat dissipation efficiency, and increase the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

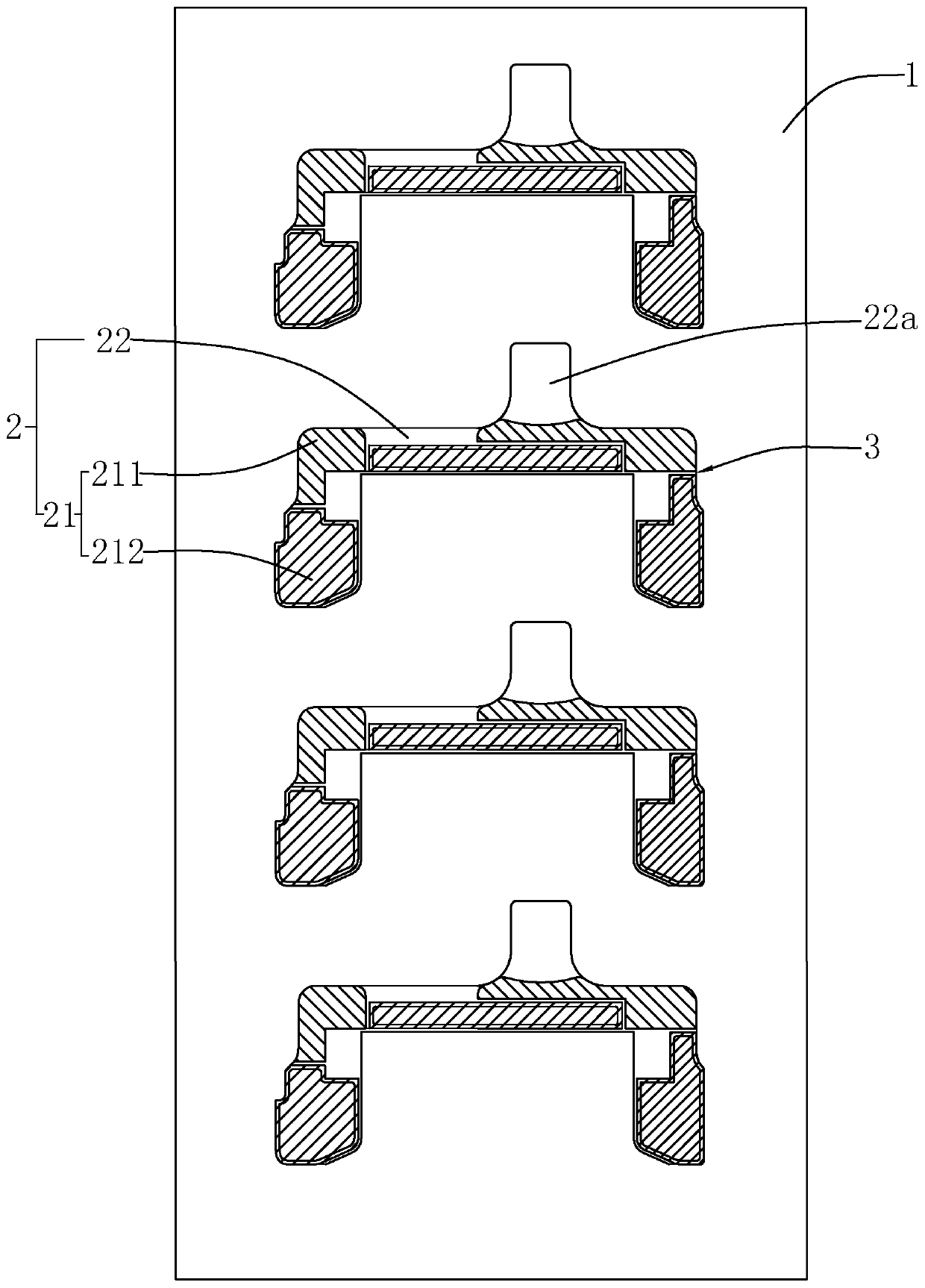

[0044] refer to figure 1 , is a kind of heat-dissipating conductive double-sided adhesive disclosed by the present invention, comprising a carrier layer 1, a colloid layer 2 and a release layer 22 arranged in sequence from bottom to top, wherein the carrier layer 1 is a transparent silicone protective film, and the colloid layer 2 is located above the bearing layer 1, and the colloidal layer 2 and the release layer 22 form a colloidal unit 21, the number of colloidal units 21 is multiple, and the plurality of colloidal units 21 are arranged at intervals along the length direction of the bearing layer 1 on the bearing layer 1 , and the bearing layer 1 can finally be rolled into a roll that occupies a small space and is easy to transport.

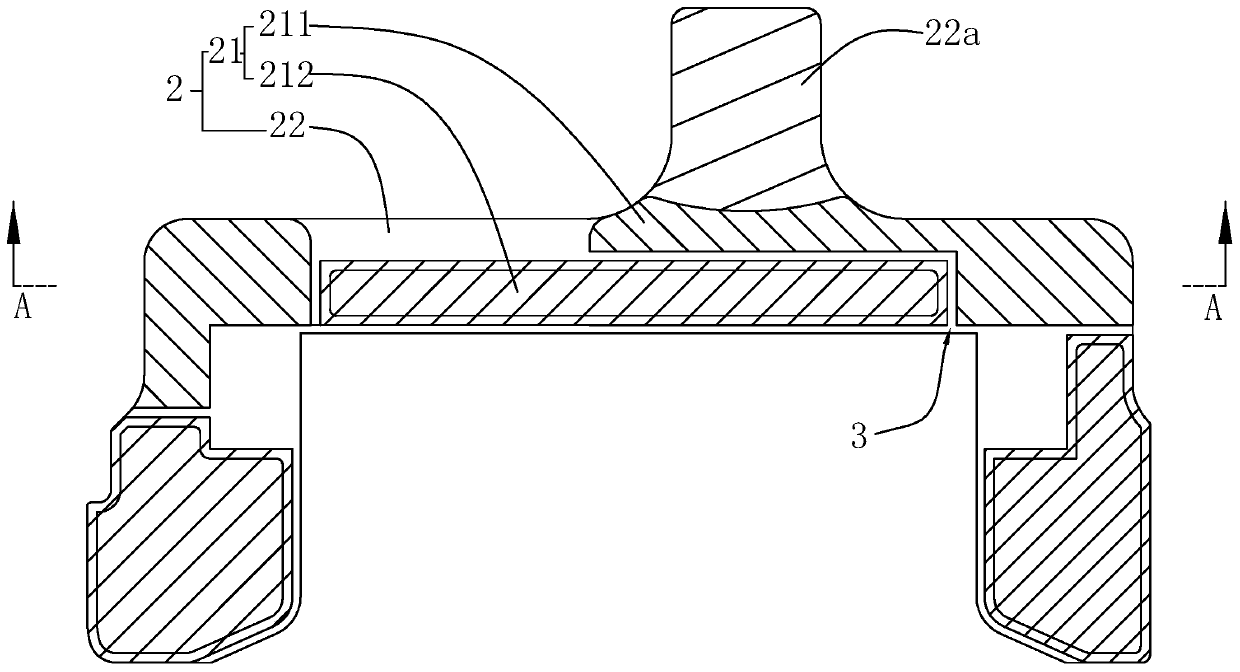

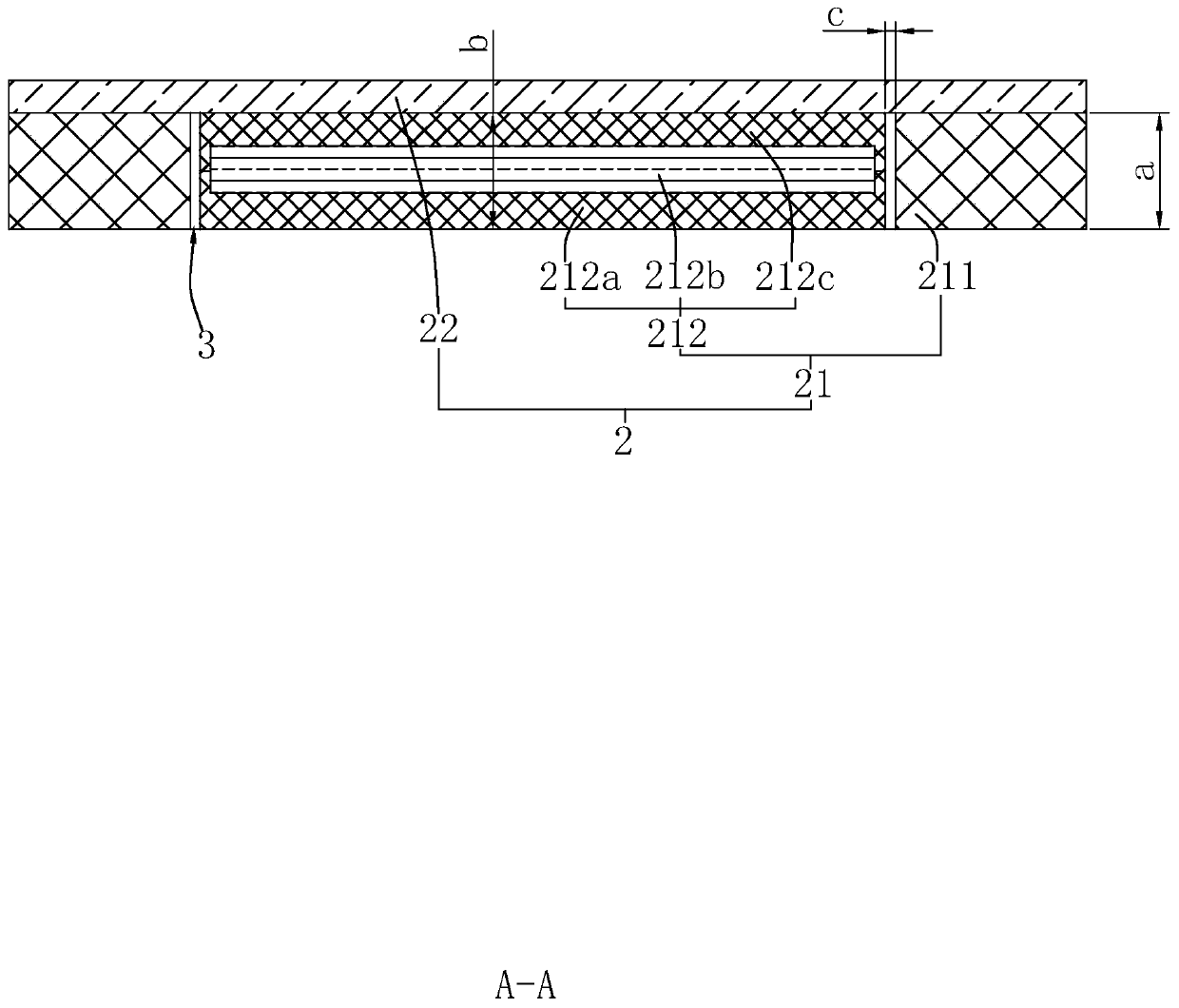

[0045] refer to figure 2 and image 3 , the colloid layer 2 includes a conductive adhesive layer and a heat dissipatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com