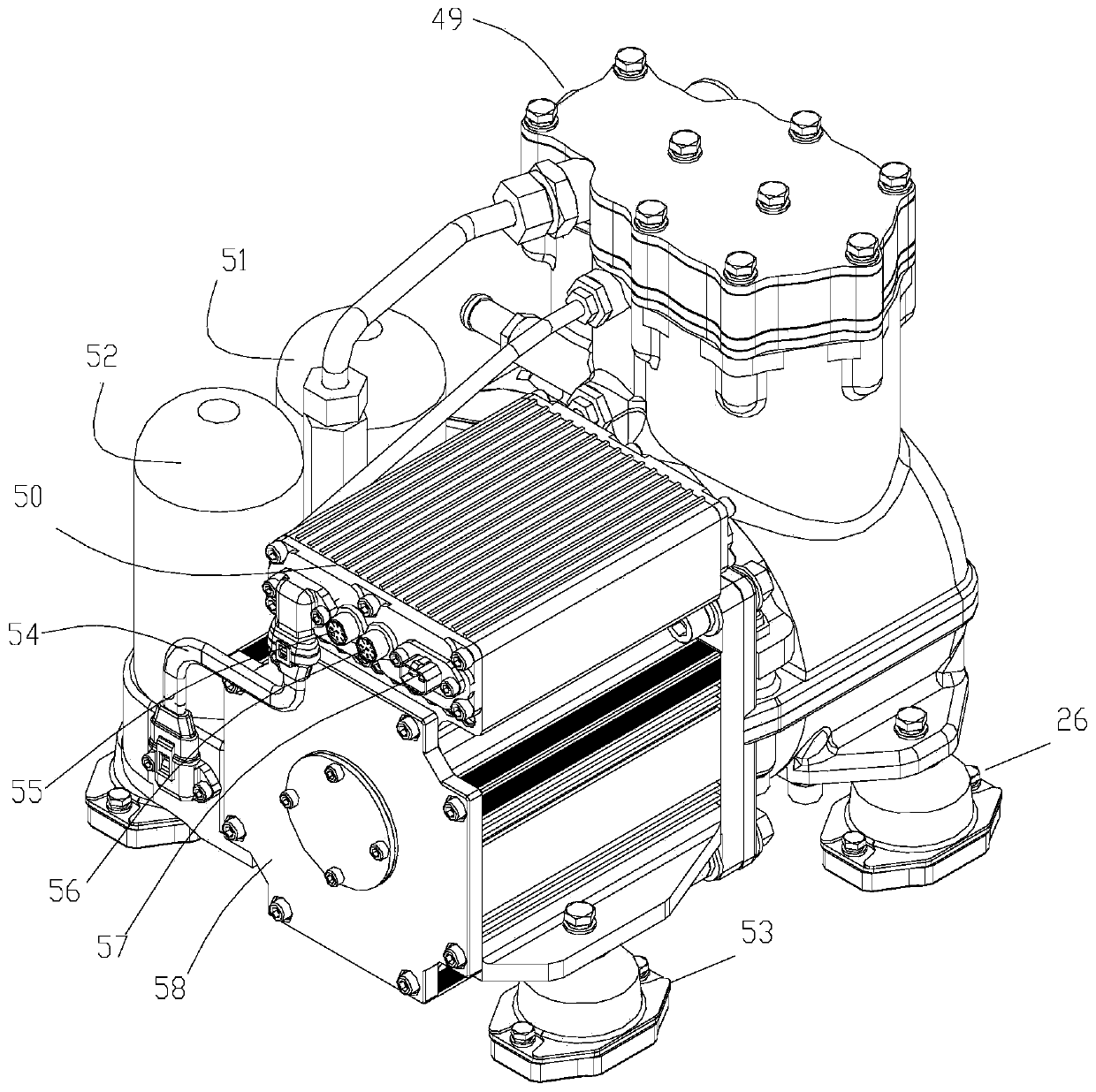

Vehicle air compressor and intelligent air supply system device thereof

A technology for air compressors and vehicles. It is applied in the arrangement of pumps/compressors, brake transmission devices, mechanical equipment, etc. It can solve the problems of excessive shape and position tolerance, difficult temperature, poor structural strength, etc., and achieve reduced operation. Vibration, high protection level, air source cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The content of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them. The embodiments in the present invention and other embodiments obtained by persons of ordinary skill in the art without creative efforts all belong to the protection scope of the present invention.

[0045] In order to solve the above-mentioned technical defect that prior art exists, the present invention adopts following structure:

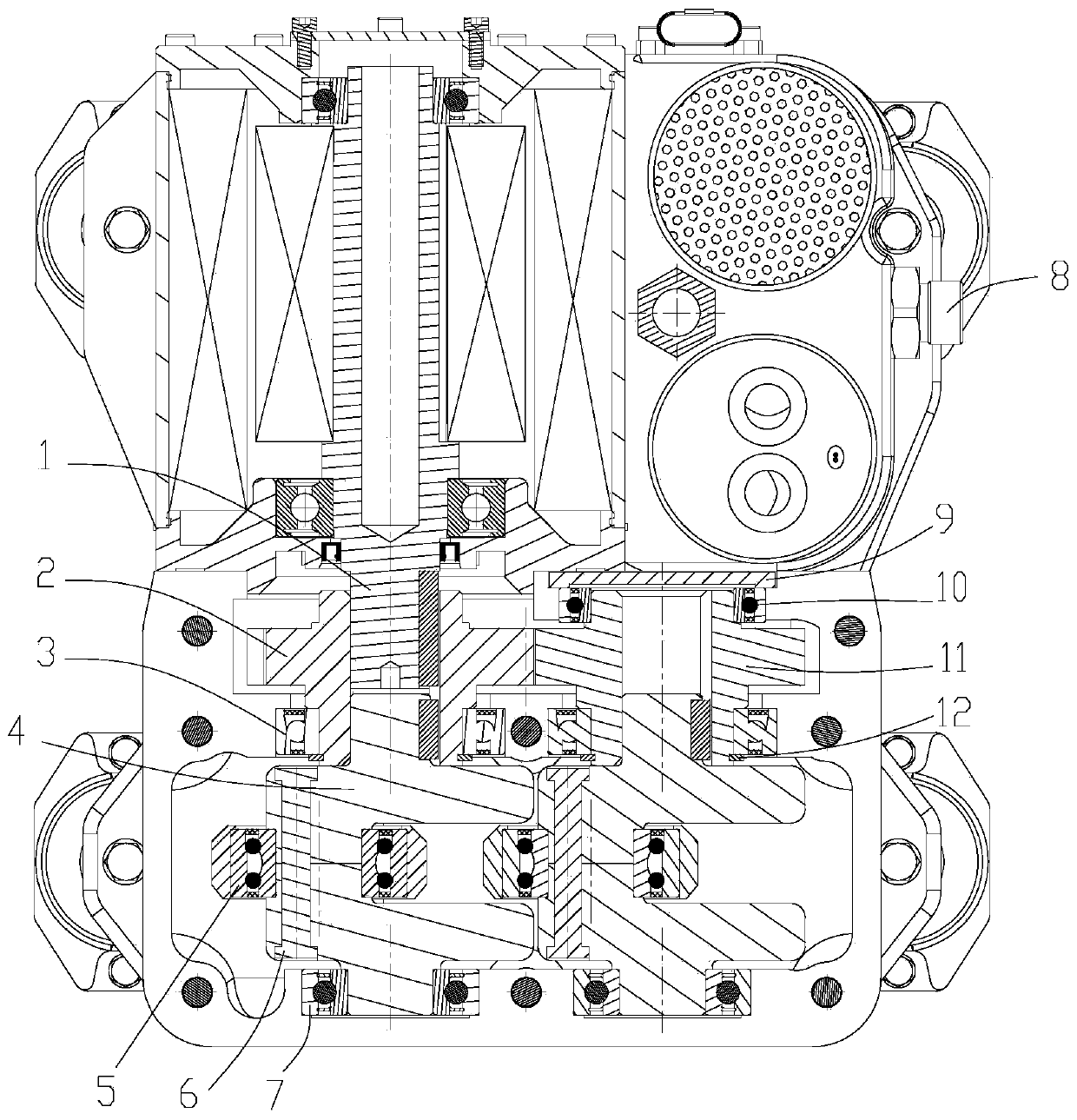

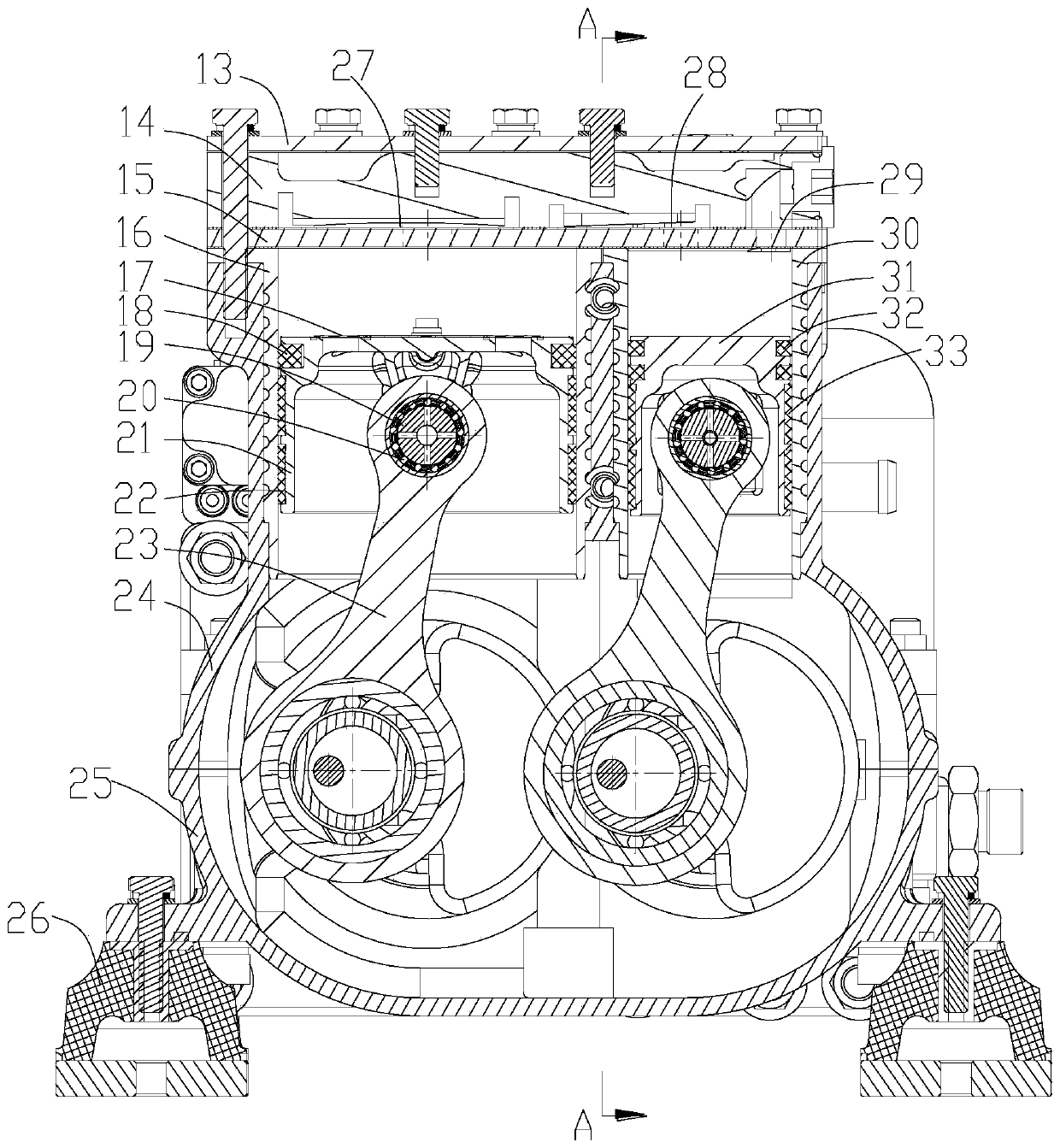

[0046] First: Adopt a counter-rotating transmission structure to greatly reduce the vibration of the air compressor;

[0047] Second: A double-support split crankshaft transmission structure is adopted to ensure the strength of multi-point support. At the same time, this structure effectively solves the problem of excessive deviation of the shape and position of the two cranks caused by the processing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com