Light-emitting device

A technology of a light-emitting device and a wavelength conversion device, which is applied to lighting devices, light guides of lighting devices, components of lighting devices, etc., can solve the problems of low color rendering index of output light, low luminous efficiency, insufficient blue light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

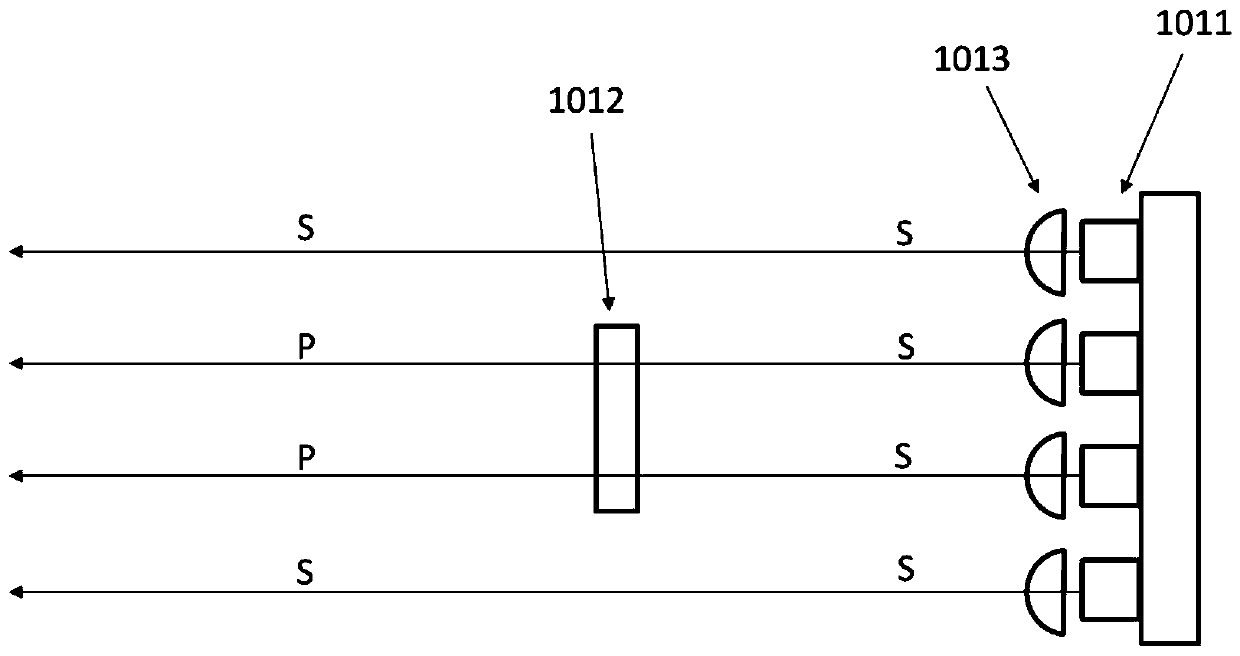

[0138] Such as Figure 10 As shown, the first laser light source 101 is provided with a blue light (central wavelength is 460nm) laser and a collimating lens, and a half-wave plate is arranged in front of some of the lasers, so the first laser light source 101 can emit nearly parallel blue light (central wavelength 460nm) and enter the polarizing beam splitter 102, and these light rays include the light of S-polarized light and P-polarized light relative to the incident plane of the polarizing beam splitter 102. Here the polarizing beam splitter 102 is selected to be a narrow-band (440-470nm) polarizing cube beam splitter. For blue light (the center wavelength is 460nm), the polarizing beam splitter 102 can reflect the S polarized light and transmit the P polarized light. For the wavelength longer than 470nm Visible light (such as green light) can be transmitted by the polarizing beam splitter 102 . The polarization beam splitter 102 transmits the P-polarized light in the inc...

Embodiment 2

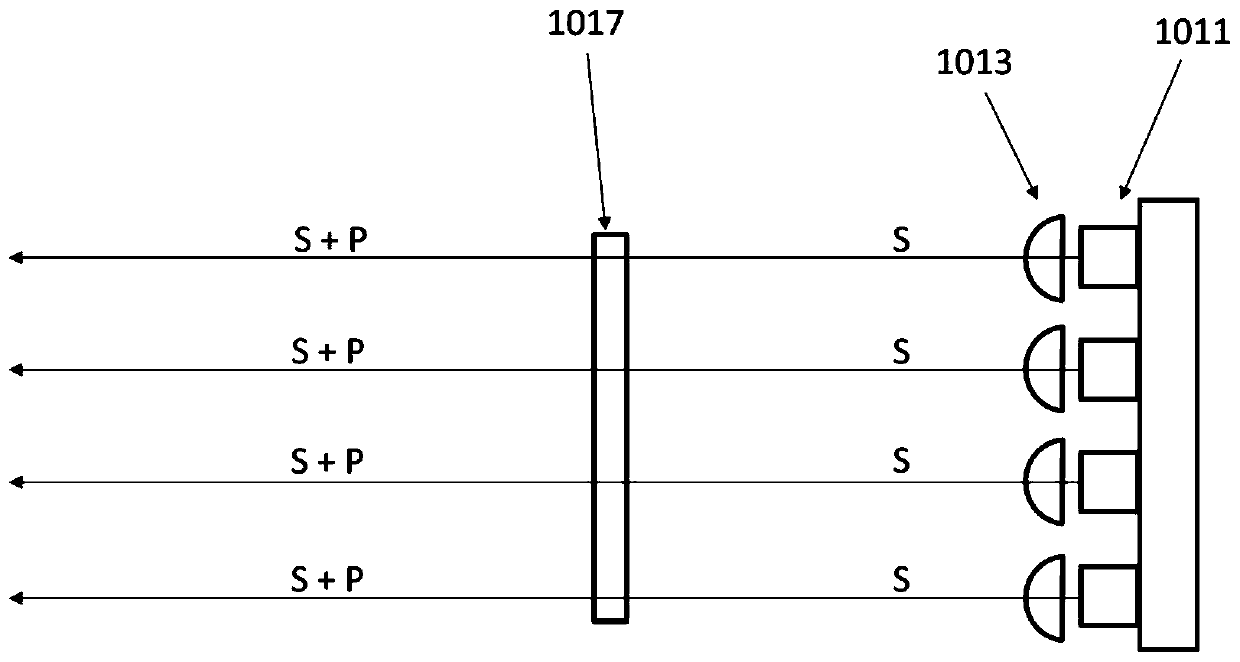

[0143] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the polarizing beam splitter 102 selected in this embodiment is flat rather than cube-shaped, and it is lighter than the cube-shaped polarizing beam splitter, so that the whole device can be made Less weight. Other structures and working methods of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0145] Such as Figure 12As shown, the difference between this embodiment and Embodiment 2 is that a second wave plate 112 is used in the second optical path, because in this embodiment, the blue light in the second optical path is not completely absorbed by the first wavelength conversion device. 107 is absorbed by the wavelength conversion material, and the remaining blue light and green light are reflected back to the second light concentrating element 106 by the reflective substrate of the first wavelength conversion device 107 . The second wave plate 112 is a quarter wave plate, which can change its polarization state for blue light (center wavelength is 460nm). The blue light passes through the second wave plate 112 twice successively, and its polarization direction changes from the original S polarized light to P polarized light. Specifically, after the blue light passes through the second wave plate 112 for the first time, it changes from the original S-polarized ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com