A kind of self-supporting p/cnts composite flexible film and its preparation method and application

A flexible thin film, self-supporting technology, applied in the direction of final product manufacturing, secondary battery manufacturing, active material electrodes, etc., to achieve the effect of simple synthesis process, ease of fragmentation, and slow down the poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

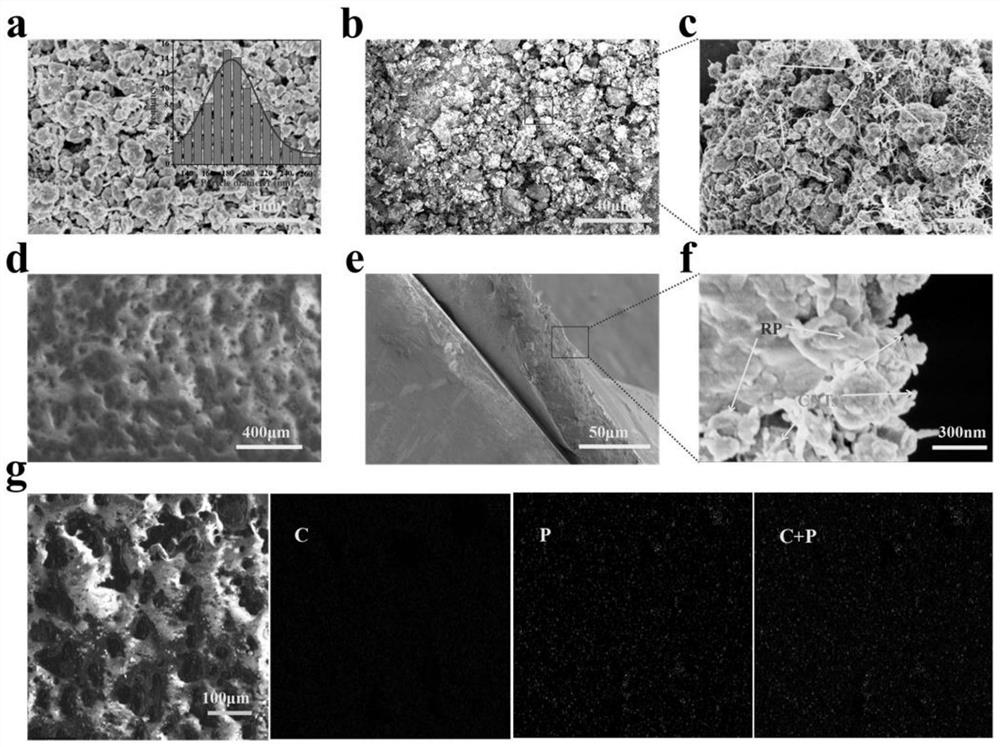

[0026] The invention provides a method for preparing a highly elastic self-supporting P / CNTs composite flexible film, comprising the following steps:

[0027] S1, the preparation of nano-scale red phosphorus:

[0028] Carry out 4 hours of high-energy ball milling treatment on commercial red phosphorus (the ratio of red phosphorus to steel balls is 10:1), break the micron-sized red phosphorus into nano-sized red phosphorus, and obtain nano-sized red phosphorus A;

[0029] S2. Preparation of P / CNTs:

[0030] Add carbon nanotubes CNTs to red phosphorus A and continue ball milling for 1 hour to obtain B(P / CNTs). The weight ratio of red phosphorus A to CNTs is (6-9):(4-1).

[0031] S3. Preparation of highly elastic self-supporting P / CNTs composite flexible film:

[0032] Stir B(P / CNTs) and SBS rubber with toluene at a mass ratio of (6-9):(4-1) for 2-3 hours to obtain a certain concentration of slurry C; finally, apply slurry C on PET On the film, after natural drying at room tem...

Embodiment 1

[0039] Step 1, the preparation of nanoscale red phosphorus:

[0040] Carry out 4 hours of high-energy ball milling treatment on commercial red phosphorus (the ratio of red phosphorus to steel balls is 10:1), break the micron-sized red phosphorus into nano-sized red phosphorus, and obtain nano-sized red phosphorus A;

[0041] Step 2, preparation of P / CNTs:

[0042] Add CNTs to red phosphorus A and continue ball milling for 1 hour to obtain B(P / CNTs), the weight ratio of red phosphorus to CNTs is 6:4.

[0043] Step 3, preparation of highly elastic self-supporting P / CNTs composite flexible film:

[0044] Stir B and SBS rubber in toluene at a ratio of 6:4 for 2 hours to obtain a certain concentration of slurry C; finally, apply slurry C on a PET film, and after natural drying at room temperature, the prepared film can be It is easily peeled off from the PET film to obtain a self-supporting flexible film D with certain elasticity.

[0045] A highly elastic self-supporting P / CNTs c...

Embodiment 2

[0049] Step 1, the preparation of nanoscale red phosphorus:

[0050] Carry out 4 hours of high-energy ball milling treatment on commercial red phosphorus (the ratio of red phosphorus to steel balls is 10:1), break the micron-sized red phosphorus into nano-sized red phosphorus, and obtain nano-sized red phosphorus A;

[0051] Step 2, preparation of P / CNTs:

[0052] Add CNTs to red phosphorus A and continue ball milling for 1 hour to obtain B(P / CNTs), the weight ratio of red phosphorus to CNTs is 7:3.

[0053] Step 3, preparation of highly elastic self-supporting P / CNTs composite flexible film:

[0054] Stir B and SBS rubber in toluene at a ratio of 7:3 for 3 hours to obtain a certain concentration of slurry C; finally, apply slurry C on a PET film and dry it naturally at room temperature to obtain a film that can It is easily peeled off from the PET film to obtain a self-supporting flexible film D with certain elasticity.

[0055] A highly elastic self-supporting P / CNTs comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com