Dual-layer composite structured ternary positive electrode material and preparation method therefor

A cathode material, double-layer composite technology, applied in structural parts, nanotechnology for materials and surface science, electrical components, etc., can solve the problems of ternary cathode material cycle performance and safety performance that cannot meet market demand, etc. Improve safety stability and cycle stability, reduce reactivity, and alleviate the effect of particle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

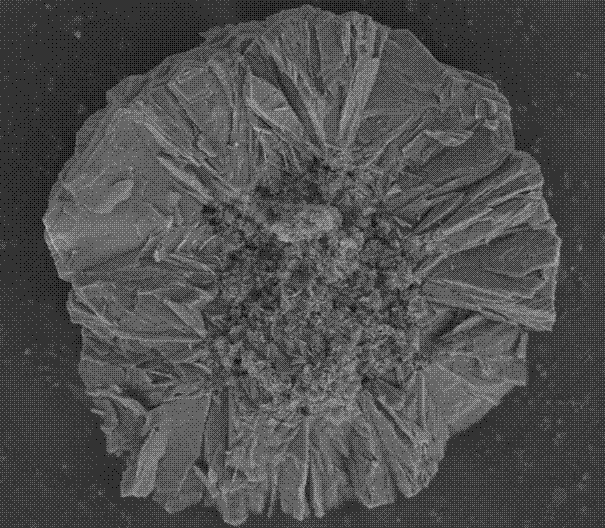

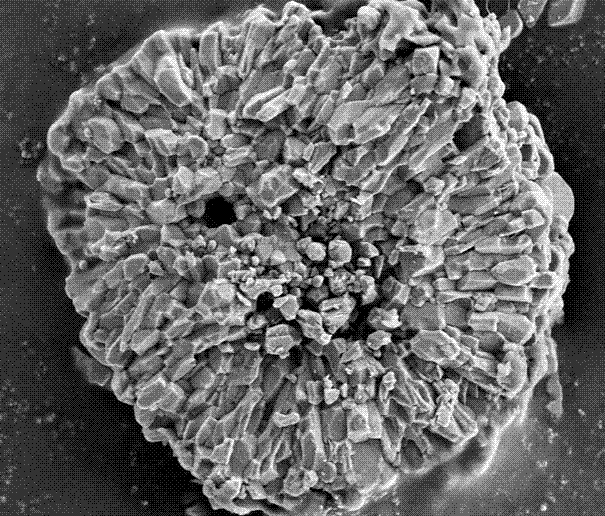

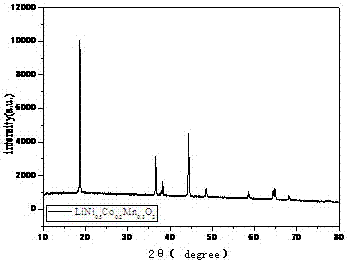

Image

Examples

Embodiment 1

[0033] A preparation method for a double-layer composite structure ternary positive electrode material, comprising the steps of:

[0034] 1) Synthetic inner structure

[0035] a) Prepare nickel-cobalt-manganese salt solution: accurately weigh nickel salt, cobalt salt, and manganese salt according to the molar ratio of 5:2:3, dissolve them in deionized water, and pass nitrogen to remove oxygen to obtain 6L 2 mol / L nickel-cobalt-manganese salt solution ;

[0036] b) Prepare 0.5L complexing agent solution A, 1L complexing agent solution B and 6L precipitant solution, and pass nitrogen to remove oxygen; complexing agent solution A is 0.3 mol / L ammonia solution; complexing agent solution B is 4mol The ammonia solution of / L; Precipitant solution is the sodium hydroxide aqueous solution of 4mol / L;

[0037] c) Add 0.5L of complexing agent solution A in step 1)b as the bottom liquid to the reaction kettle, pass inert gas nitrogen into the reaction kettle, then stir at a stirring spe...

Embodiment 2

[0046] A preparation method for a double-layer composite structure ternary positive electrode material, comprising the steps of:

[0047] 1) Synthetic inner structure

[0048] a) Prepare nickel-cobalt-manganese salt solution: accurately weigh nickel salt, cobalt salt, and manganese salt according to the molar ratio of 8:1:1, dissolve them in deionized water, and pass nitrogen to remove oxygen to obtain 40L 2mol / L nickel-cobalt-manganese salt solution;

[0049] b) Prepare 20L of complexing agent solution A, 12L of complexing agent solution B and 40L of precipitating agent solution, and pass nitrogen to remove oxygen; complexing agent solution A is 0.5 mol / L ammonia solution; complexing agent solution B is 4mol / L The ammonia solution of L; Precipitant solution is the sodium hydroxide aqueous solution of 4mol / L;

[0050] c) Add 20L of complexing agent solution A in step 1)b as the bottom liquid to the reactor, feed the inert gas nitrogen into the reactor, then stir at a stirring...

Embodiment 3

[0059] Change the stirring speed in step 1) c in Example 1 to 700r / min, and the others are consistent with Example 1.

[0060] The double-layer composite structure ternary positive electrode material obtained in this example was used as the positive electrode material to prepare a button battery, and its electrochemical performance was tested. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com