Novel composite cathode material containing negative thermal expansion material and application thereof in preparation of SOFC

A negative thermal expansion material, composite cathode technology, applied in fuel cells, battery electrodes, solid electrolyte fuel cells and other directions, can solve the problems of limited TEC adjustment, reduced cathode oxygen reduction reaction activity, and reduced performance, etc., to improve battery performance, Improved thermal stability and less restrictive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

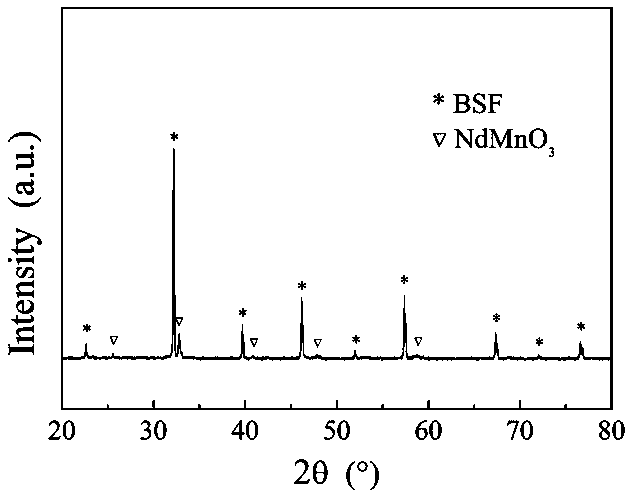

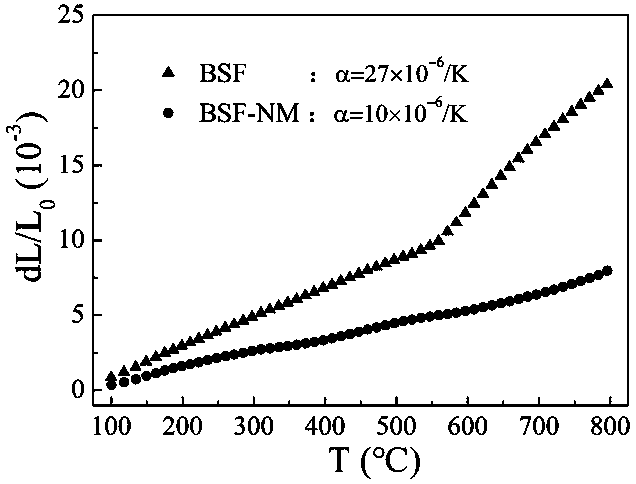

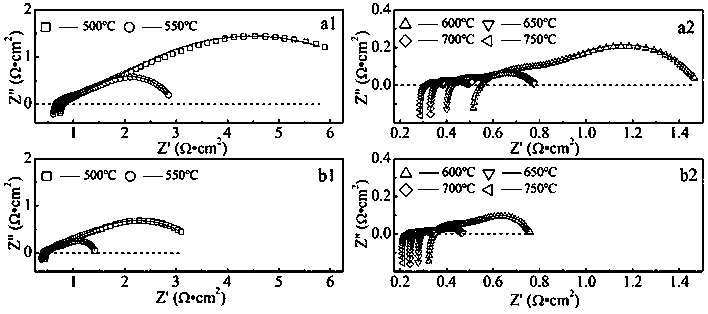

[0027] A new type of composite cathode material containing a negative thermal expansion material, the new type of composite cathode material is mainly composed of a mixed ion-electronic conductor and a negative thermal expansion material, and the negative thermal expansion material accounts for 30% of the total weight of the two in weight percentage; The mixed ion-electronic conductor is BSF powder, and the chemical formula is Ba 0.5 Sr 0.5 FeO 3-δ ; The negative thermal expansion material is perovskite oxide NdMnO 3 (NM).

[0028] The specific preparation method of the above-mentioned novel composite cathode material containing negative thermal expansion material is as follows:

[0029] S1: According to metal ion Ba 2+ , Sr 2+ , Fe 3+ The molar ratio is 1:1:2 to weigh Ba(NO 3 ) 2 , Sr(NO3) 2 , Fe(NO 3 ) 3 ·9H 2 O, dissolved in deionized water (the amount of deionized water for preparing 0.01mol BSF material is 400ml) to form a mixed metal salt solution, and the mo...

Embodiment 2

[0035] A new type of composite cathode material containing negative thermal expansion material, the new type of composite cathode material is mainly composed of mixed ion-electronic conductor and negative thermal expansion material, and in weight percentage, the negative thermal expansion material accounts for 10% of the total weight of the two; The mixed ion-electronic conductor is BSF powder, and the chemical formula is Ba 0.5 Sr 0.5 FeO 3-δ ; The negative thermal expansion material is perovskite oxide NdMnO 3 (NM).

[0036] Refer to Example 1 for the specific preparation method of the above-mentioned novel composite cathode material containing negative thermal expansion material.

Embodiment 3

[0038] A new type of composite cathode material containing negative thermal expansion material, the new type of composite cathode material is mainly composed of mixed ion-electronic conductor and negative thermal expansion material, and the negative thermal expansion material accounts for 60% of the total weight of the two in weight percentage; The mixed ion-electronic conductor is BSF powder, and the chemical formula is Ba 0.5 Sr 0.5 FeO 3-δ ; The negative thermal expansion material is perovskite oxide NdMnO 3 (NM).

[0039] Refer to Example 1 for the specific preparation method of the above-mentioned novel composite cathode material containing negative thermal expansion material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com