A power battery tab cooling system with exhaust gas

A power battery and exhaust gas exhaust technology, which is applied to secondary batteries, exhaust plug devices, battery pack components, etc., can solve problems such as poor heat transfer, uneven flow field, and low thermal conductivity of diaphragm materials, and achieve It is convenient for long-term and safe use, improves safety and stability, and enhances the effect of heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

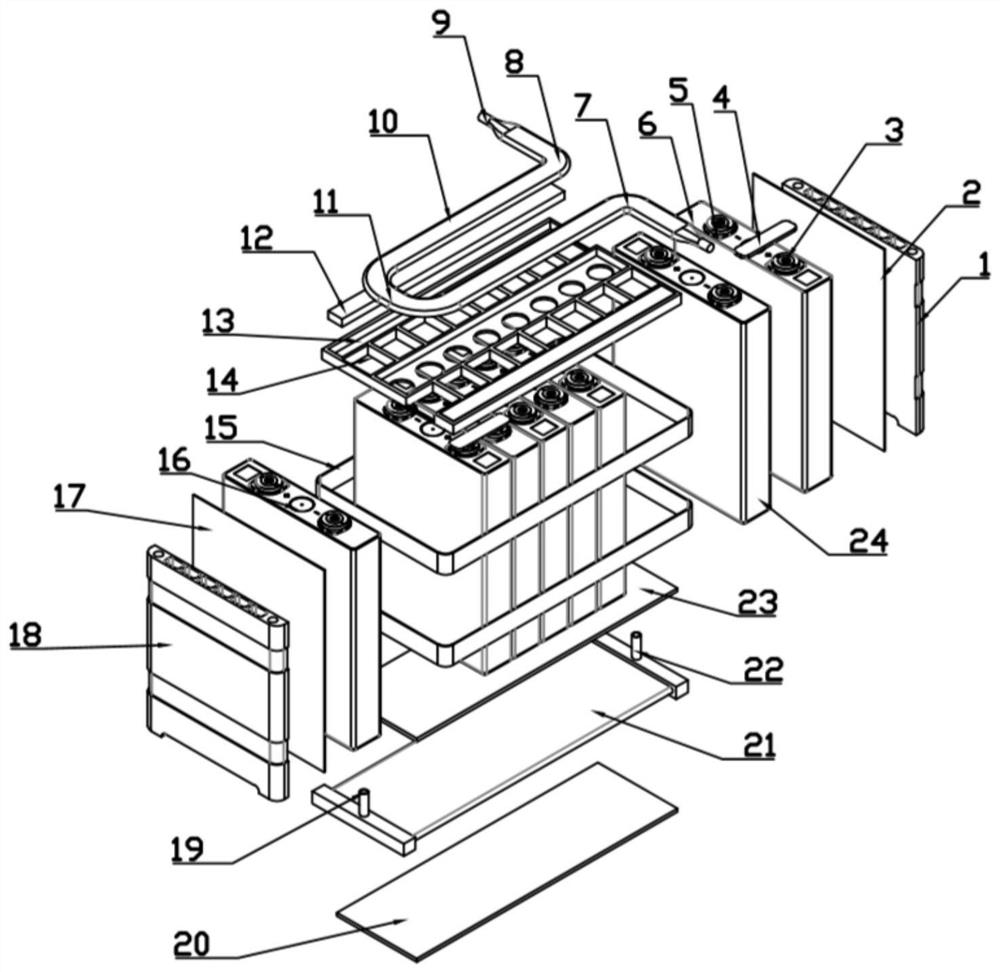

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0018] combine figure 1 , the present invention provides a power battery tab heat dissipation system that can discharge exhaust gas, without changing the original thermal management system, coupling the advantages of air-cooled and liquid-cooled thermal management methods, and effectively solves the traditional liquid-cooled thermal management method The disadvantage of not being able to discharge the exhaust gas generated in the thermal management system; at the same time, the thermal management method of heat dissipation by battery tabs can efficiently dissipate heat from the battery module and further improve the temperature uniformity of the system; the system is provided with multi-layer safety protection, It can better avoid the current frequent battery thermal runaway problem and promote the development of new energy hybrid and pure electric vehicles.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com