Composite material for simultaneous generation of oxygen and active oxygen under near-infrared light excitation, preparation method and application thereof

A near-infrared light and composite material technology, applied in the field of composite materials, can solve the problems affecting PDT efficiency, accurate matching of oxygen and photosensitizers, slow space transfer, etc., to achieve the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of a composite material for simultaneously generating oxygen and active oxygen under near-infrared light excitation, comprising the following steps:

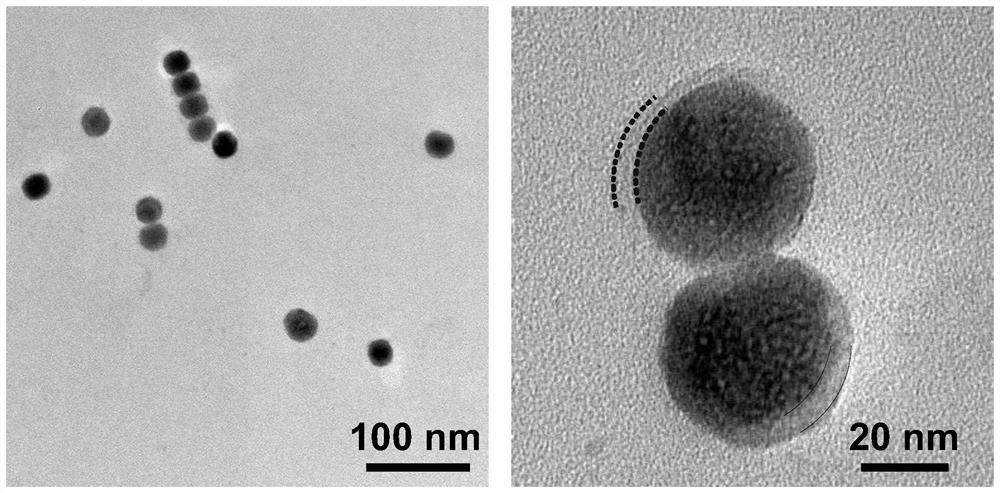

[0034] Step 1. Preparation of Upconversion Nanoparticles

[0035] Upconversion nanoparticles are prepared by the following methods:

[0036] Weigh 1mM rare earth acetate, wherein Y:Yb:Er=78:20:20, and 10mM sodium fluoride into a three-necked flask containing 10mL oleylamine and 10mL octadecene, continue to pass nitrogen and heat to 120 °C for 1 h; then slowly heated to 320 °C and stirred for 1 h, naturally cooled to room temperature; added absolute ethanol, centrifuged to obtain a precipitate, washed with water and ethanol three times each, and finally obtained up-conversion nanoparticles, dispersed in chloroform; finally, 1 mL of 0.1M cetyltrimethyl bromide solution was added to the chloroform solution of upconversion nanoparticles, stirred at 70° C. for 4 hours, centrifuged, ...

Embodiment 1

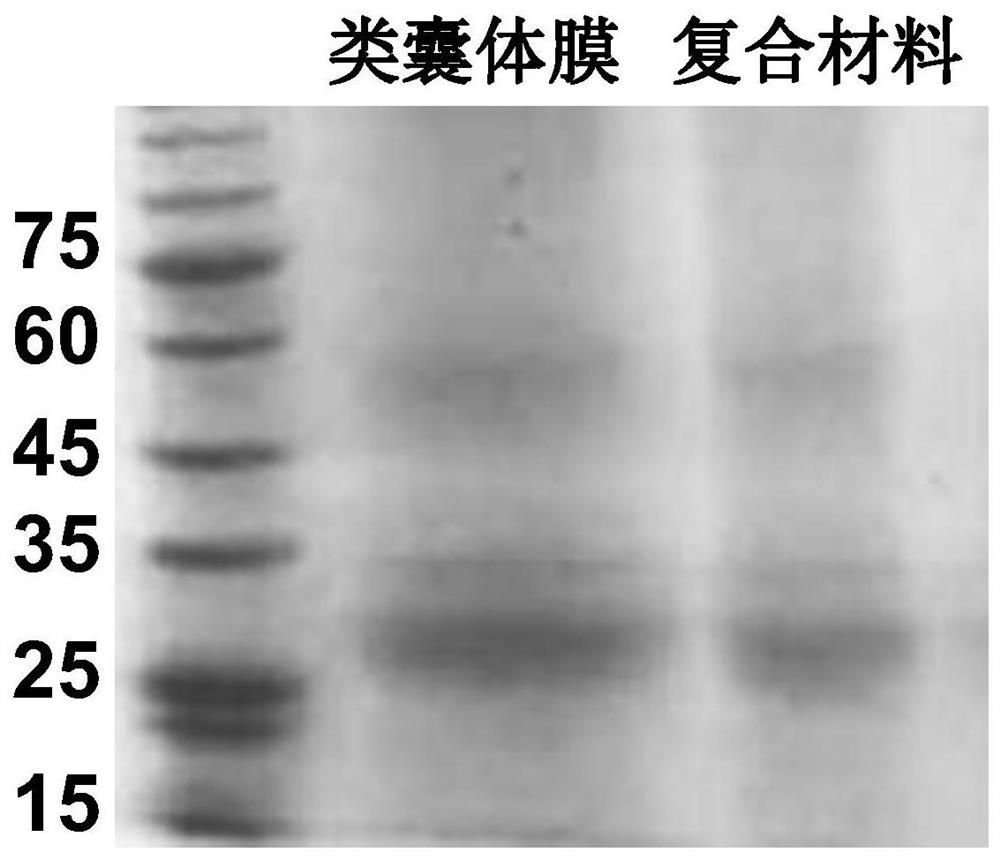

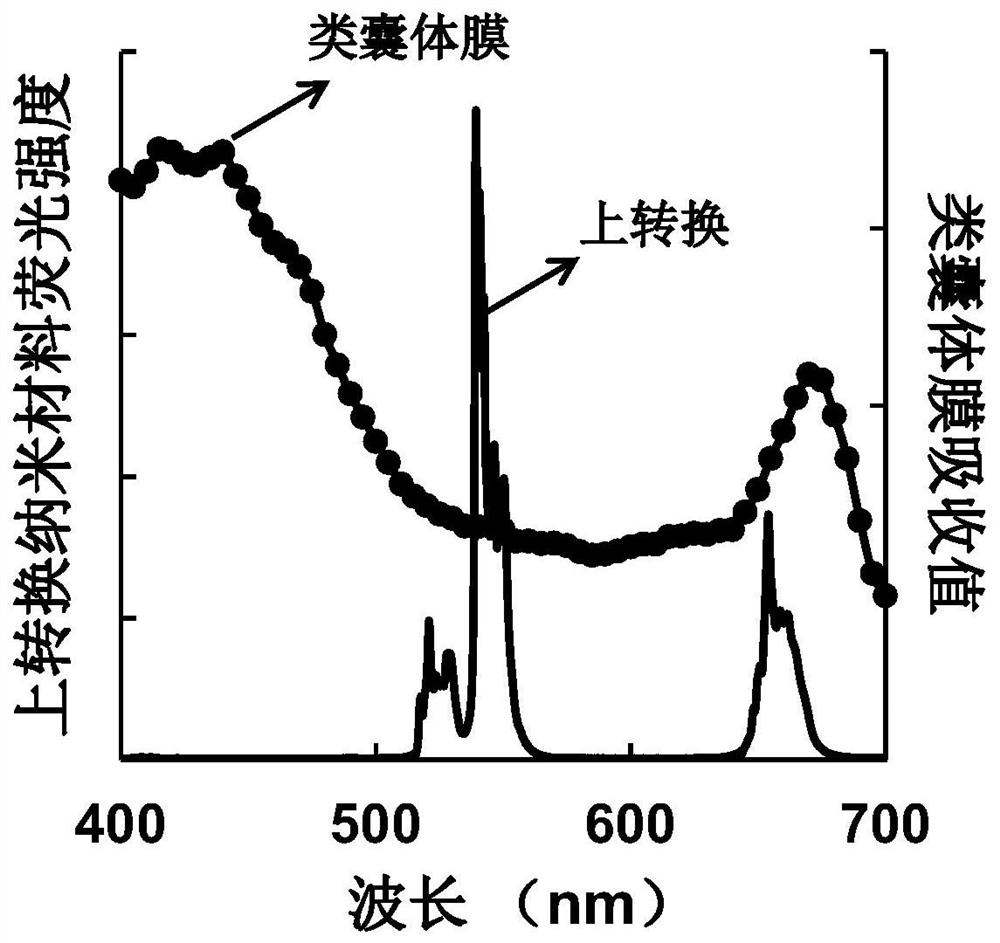

[0045] The preparation of the composite material used for simultaneous generation of oxygen and active oxygen under the excitation of near-infrared light provided by the present invention, the specific steps are as follows:

[0046] 1. Synthesis of upconversion nanoparticles:

[0047] Weigh 1mM rare earth acetate (wherein Y:Yb:Er=78:20:20) and 10mM sodium fluoride into a three-necked flask containing 10mL oleylamine and 10mL octadecene, continue to feed nitrogen and heat To 120 ℃, keep 1h. Then it was heated slowly to 320° C. and stirred for 1 h, and then cooled to room temperature naturally. Add absolute ethanol, centrifuge to obtain a precipitate, wash with water and ethanol three times, and finally obtain upconversion nanoparticles, which are dispersed in chloroform. Finally, 1 mL of hexadecyltrimethyl bromide solution (0.1 M) was added to the chloroform solution of upconverting nanoparticles, stirred at 70° C. for 4 hours, centrifuged, washed with water, and dried to obt...

Embodiment 2

[0073] Synthesis of upconverting nanomaterials and thylakoid membrane composites with an excitation wavelength of 808 nm.

[0074] 1. Synthesis of upconversion nanoparticles:

[0075] Weigh 0.1mM rare earth acetate (wherein Y:Yb:Er:Nd=38:10:1:1) and 10mM sodium fluoride into a three-necked flask containing 10mL oleylamine and 10mL octadecene, and keep Bubble nitrogen and heat to 120°C for 1h. Then it was heated slowly to 340° C. and stirred for 1 h, and then cooled to room temperature naturally. Add absolute ethanol, centrifuge to obtain a precipitate, wash with water and ethanol three times, and finally obtain upconversion nanoparticles, which are dispersed in chloroform. Finally, 1 mL of hexadecyltrimethyl bromide solution (0.1 M) was added to the chloroform solution of upconverting nanoparticles, stirred at 70° C. for 4 hours, centrifuged, washed with water, and dried to obtain aqueous phase upconverting nanoparticles.

[0076] 2. Extraction of thylakoid membrane:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com