Small hollow gold nanorod and preparation method and application thereof

A gold nanorod, hollow technology is applied in the field of small hollow gold nanorod and its preparation, and achieves the effects of high tumor enrichment, good homogeneity and good pharmacokinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

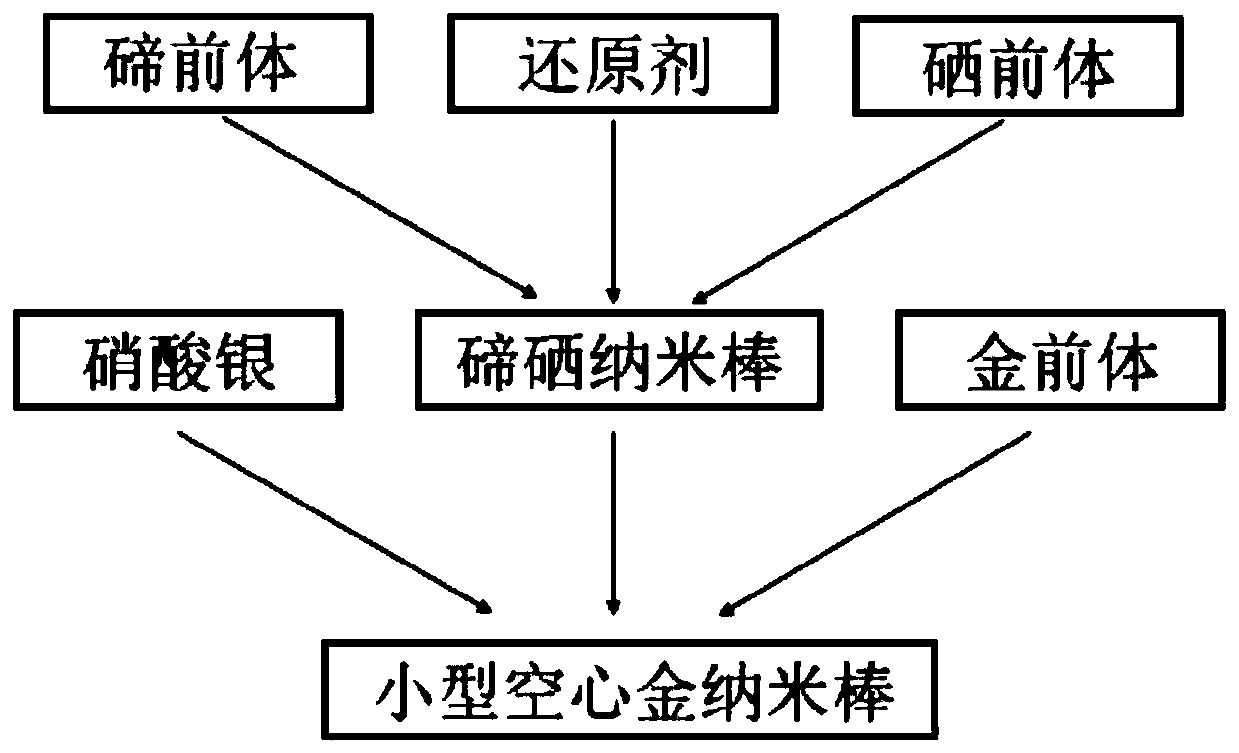

[0025] Such as figure 1 As shown, the embodiment of the present invention provides a preparation method of small hollow gold nanorods, the preparation method comprising the following steps:

[0026] (a) Add the tellurium precursor into the solution containing the reducing agent, fully stir the reaction at a temperature of 30°C to 50°C for 1min to 5min, then add the selenium precursor to continue the reaction for 3min to 10min, wherein the tellurium precursor and the selenium The molar ratio of the precursor is 1:1 to 1:3. After the reaction is completed, the reaction solution is diluted in a solution containing a surfactant, and after being fully stirred, solid-liquid separation is carried out to obtain a precipitate, thereby preparing tellurium selenide nanorods ;

[0027] (b) Disperse the tellurium selenide nanorods prepared in step (a) in an aqueous solution at 1°C to 25°C, add silver nitrate solution and stir for 2min to 15min, then add gold precursor to continue the reac...

Embodiment 1

[0034] (a) Add tellurium dioxide into the hydrazine hydrate solution, fully stir the reaction at 30°C for 3 minutes, then add selenous acid solution and continue the reaction for 5 minutes, wherein the molar ratio of tellurium dioxide to selenous acid is 1 : 2, after the reaction is finished, the reaction solution is diluted in a solution containing sodium lauryl sulfate, and after fully stirring, solid-liquid separation is carried out to obtain a precipitate, thereby making a tellurium selenide nanorod;

[0035](b) Disperse the tellurium-selenide nanorods prepared in step (a) in an aqueous solution at 25°C, add silver nitrate solution and stir for 2 minutes, then add gold precursors to continue the reaction for 1 minute, wherein the tellurium-selenide nanorods and gold precursors The molar ratio of silver nitrate and gold precursor is 1:1, and the molar ratio of silver nitrate and gold precursor is 1:6. Finally, add cysteine and polyethylene glycol solution and react for 1mi...

Embodiment 2

[0037] (a) Add tellurous acid into hydrazine hydrate solution, fully stir the reaction at 40°C for 5 minutes, then add sodium selenite solution and continue the reaction for 10 minutes, wherein the molar ratio of tellurous acid to sodium selenite The ratio is 1:1. After the reaction is completed, the reaction solution is diluted in a solution containing sodium lauryl sulfate, and after being fully stirred, solid-liquid separation is carried out to obtain a precipitate, thereby preparing tellurium selenide nanorods;

[0038] (b) Disperse the tellurium-selenide nanorods prepared in step (a) in an aqueous solution at 10°C, add silver nitrate solution and stir for 5 minutes, then add gold precursors to continue the reaction for 6 minutes, wherein the tellurium-selenide nanorods and gold precursors The molar ratio of silver nitrate and gold precursor is 3:2, the molar ratio of silver nitrate and gold precursor is 1:3, finally add cysteine and polyethylene glycol solution and react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com