A non-cut power shift automatic transmission

An automatic transmission and power shifting technology, which is applied to vehicle gearboxes, multi-ratio transmissions, transmissions, etc., can solve problems such as small transmission torque, long shift time, and large transmission impact, and achieve reliable braking performance , the shifting process is smooth, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

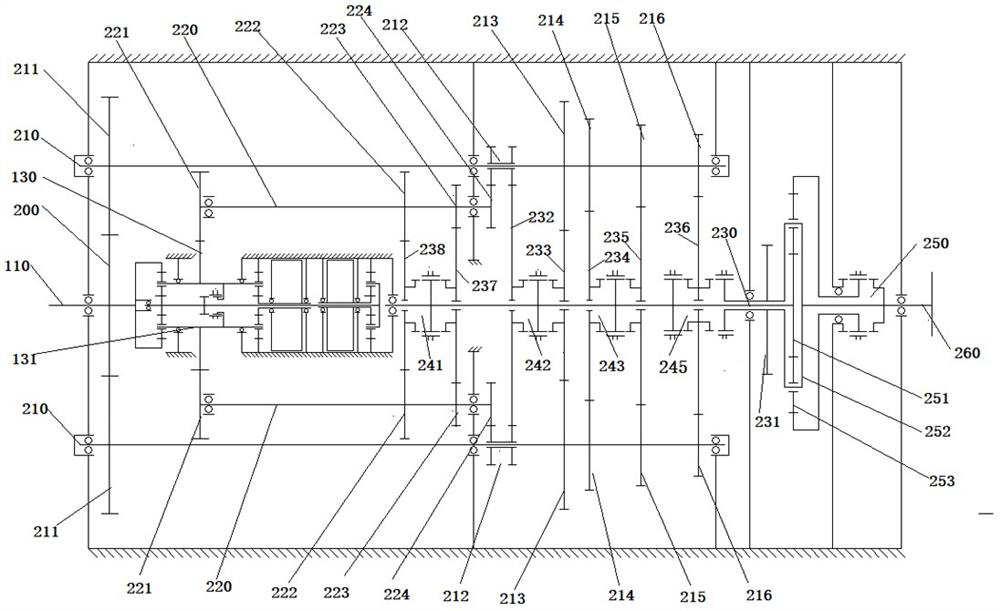

[0081] An overall structure of a non-cutting power shift automatic transmission such as image 3 As shown, its core transmission components are like figure 2 As shown, on the basis of the core transmission member, two intermediate shafts A210 are provided on both sides of the input shaft 110, and two intermediate shafts B220 are arranged, and the input shaft 110 is fixed to the input active gear 200, two The root intermediate shaft A210 is fixedly fixed to include the input driven gear 211, and the input drive gear 200 is engaged with the input driven gear 211; the hollow shaft A131 is fixed to secure the output active gear 130, and the two intermediate shafts B220 are fixed. There is an output driven gear 221, and the output driven gear 221 meshes with the output active gear 130; the two intermediate shaft A210 is fixed, and there is a fixed set of 7-15 gears 213, 5-13, active gear 214, 3-11. The active gear 215 and 1-9 gear 216, and the transmission is also provided with 7-15 fil...

Embodiment 2

[0135] like Figure 4 As shown, on the basis of the above-mentioned 16-speed automatic transmission structure, the power output shaft 260, the secondary box planetary gear mechanism, the high-end gear binding sleeve 250 and 9 gear binding sleeve 245, the P-speed gear 231 directly and the two axis 230 The connection is performed directly in two axis 230, which can be converted to an eight-speed transmission, which is mainly used in automatic shifting of vehicles such as large passenger cars.

[0136] Its main gear setting is as follows:

[0137] P file: All gear combination sleeves are in an empty position, lock the P-speed gear 231 directly, and the car is in the parking status.

[0138] N file: All gear bonding sleeves are in an empty position, and the biaxial 230 is in a free location and a non-warrant output.

[0139] The R file contains two gear positions of R1, R2, and its power transmission is as follows:

[0140] R1 gear: The gear bonding set B242 is connected to the two axi...

Embodiment 3

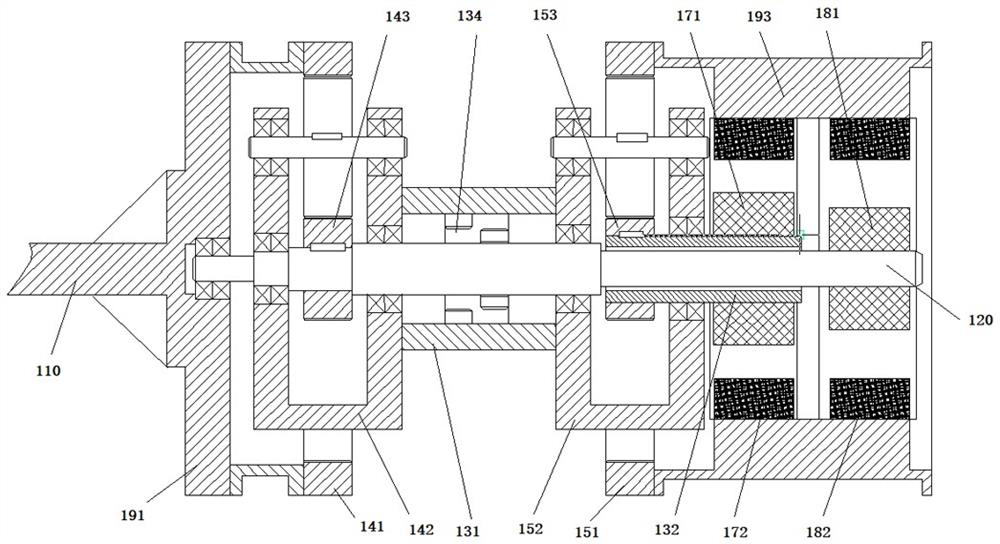

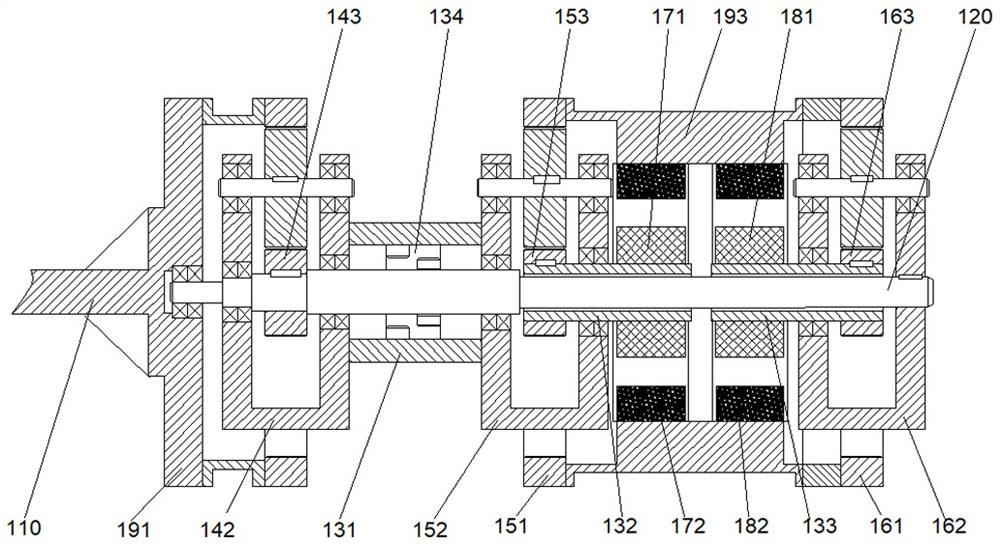

[0153] An overall structure of a non-cutting power shift automatic transmission such as Figure 5 As shown, its core transmission components are like figure 1 Indicated. The non-cutting power shift automatic transmission structure also includes a housing, a housing, an outer casing, a hollow shaft D320, a hollow shaft E330, a Ravina planetary gear mechanism, and a single-row double stage. Planetary gear mechanism. The above two planetary wheel planetary gear mechanisms are common in the Lavina planetary gear automatic transmission, including a ring gear, an outer linear wheel, an inner planet wheel, a planet carrier and a sun gear, a ring gear and a sun gear set, a sun gear? Mested several internal planet wheels, the ring gears engage the plurality of external planet wheels, the outer star wheel engage the inner planetary wheel, and the planet carrier is used to maintain the support inner planet wheels and the outer star wheel. The drive shaft A310, the hollow shaft D320, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com