Ultralow-temperature water steam capturing pump pipeline system applying refrigerating medium for cold storage

An ultra-low temperature, refrigerant carrier technology, used in condensation traps/cold partitions, pumps, refrigerators, etc., can solve problems such as reducing equipment service life, increasing the probability of compressor liquid hammer, and increasing compressor workload, etc. Achieve the effect of saving energy, improving service life and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

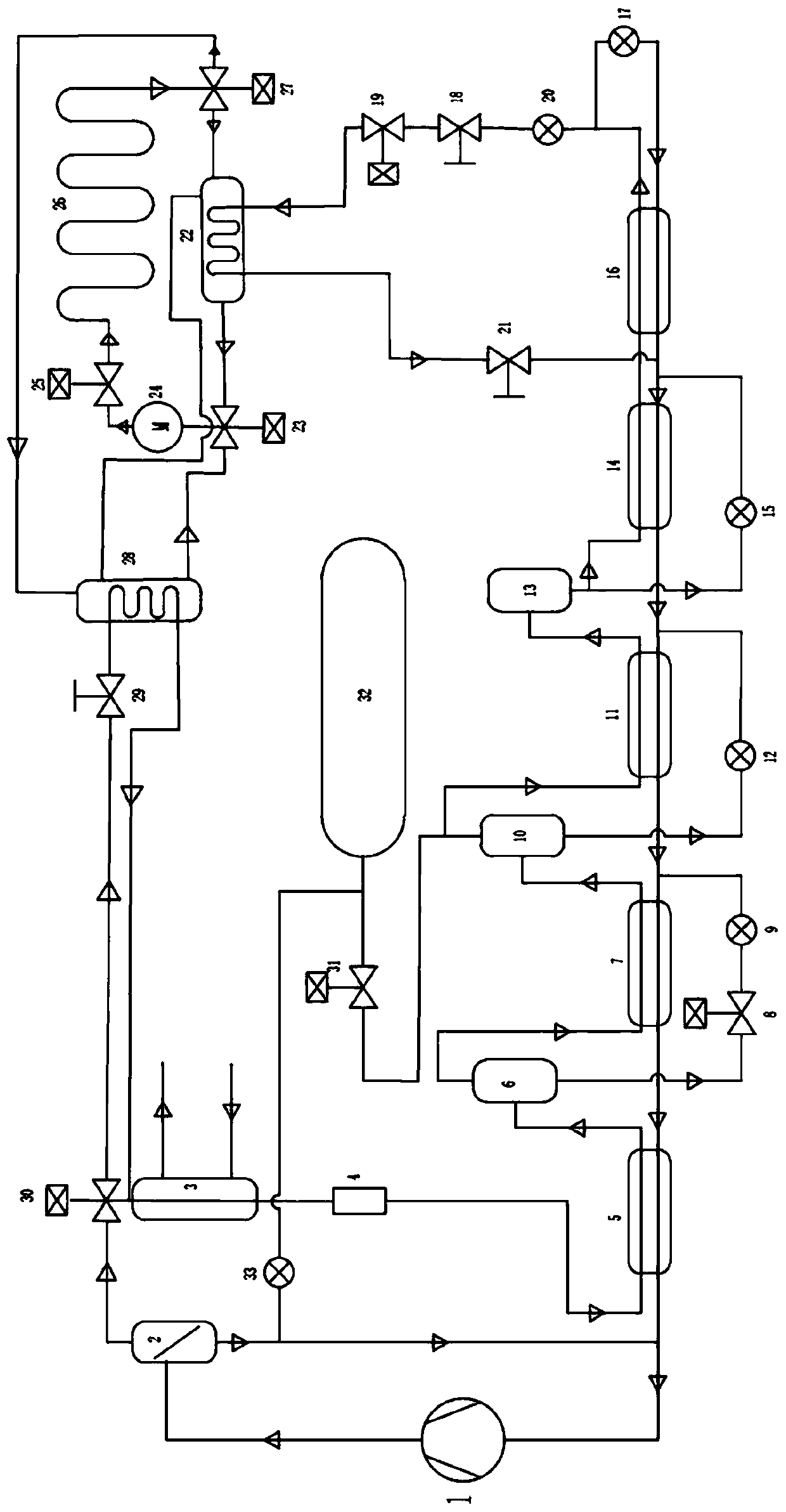

[0040] The ultra-low temperature water vapor trap pump can obtain ultra-low temperature through the self-cascade refrigeration cycle. The ultra-low temperature refrigerant directly contacts the load cold trap to exchange heat, which can reduce the temperature of the load cold trap, so that the water vapor in the outer cavity of the cold trap is adsorbed on the cold trap The outer surface, so that the inside of the cavity can obtain a higher degree of vacuum under the action of the vacuum pump. The invention uses a refrigerant carrier to store the cold capacity and cool down the cold trap installed in the vacuum coating system. It uses a low-temperature refrigerant with a high specific heat capacity. In the case of occupying a small space, the carrier in the cold tank The refrigerant can store the excess cold produced by the ultra-low temperature trap pump during standby, avoiding the problem of equipment shutdown due to low-pressure alarms due to over-cooling of the system. At ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap