Friction stir butt welding device for high-resistivity alloy and processing method

A friction stir welding and friction stir technology, which is applied in metal processing equipment, non-electric welding equipment, welding equipment, etc., can solve problems such as hindering the large-scale popularization and application of current-assisted friction stir welding, insignificant Joule effect, and low resistivity. Achieve the effect of reducing welding defects, improving weld quality and reducing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

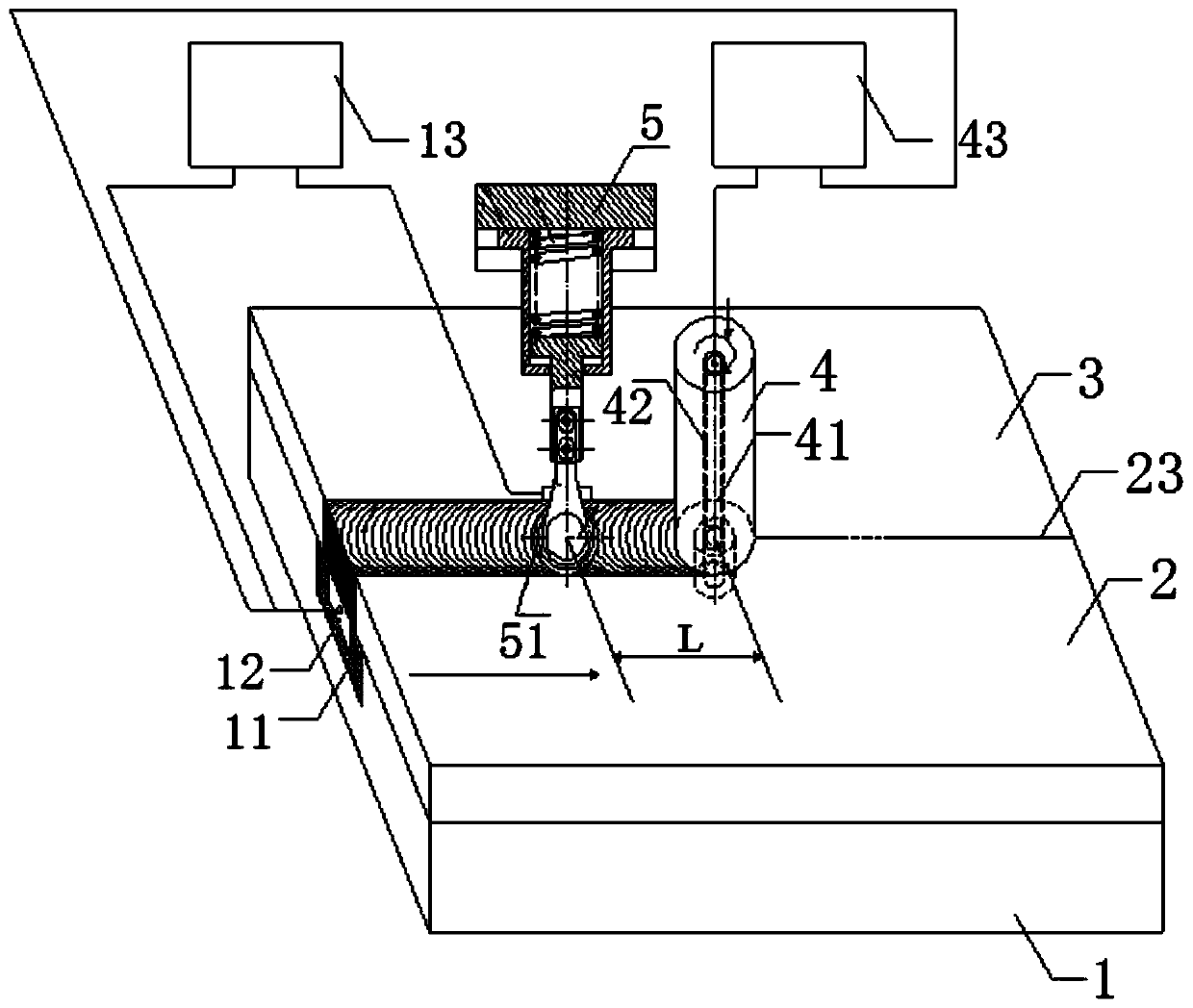

[0029] Such as figure 1As shown, a friction stir butt welding device for high-resistivity alloys includes a workbench, a friction stir welding mechanism and a rolling electrode assembly. The workbench is used to place and fix workpieces to be welded, and the workpieces to be welded include No. 1 workpiece 2 and No. 2 workpiece 3, the No. 1 workpiece 2 and No. 2 workpiece 3 are laid side by side on the surface of the worktable, and the mutual contact positions form a docking interface 23; Heat shield 1, by setting the heat shield 1, the temperature gradient in the thickness direction of the workpiece to be welded can be reduced, so that the bottom of the workpiece to be welded also has a sufficient softening effect, thereby enhancing the flow and flow of the material in the bottom area of the workpiece during welding Quantity, so that the bottom material is fully mixed, reducing welding defects at the bottom of the workpiece, and improving welding quality.

[0030] The conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com