Process for producing carbonate apatite

A technology of carbonated apatite and manufacturing method, which is applied in the direction of chemical instruments and methods, phosphorus oxyacids, phosphorus compounds, etc., can solve the problems of not knowing carbonated apatite, etc., and achieve the effect of simple process and high import rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (Material production and physical property evaluation)

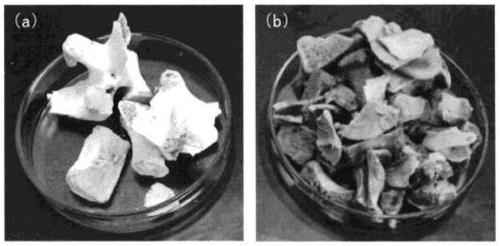

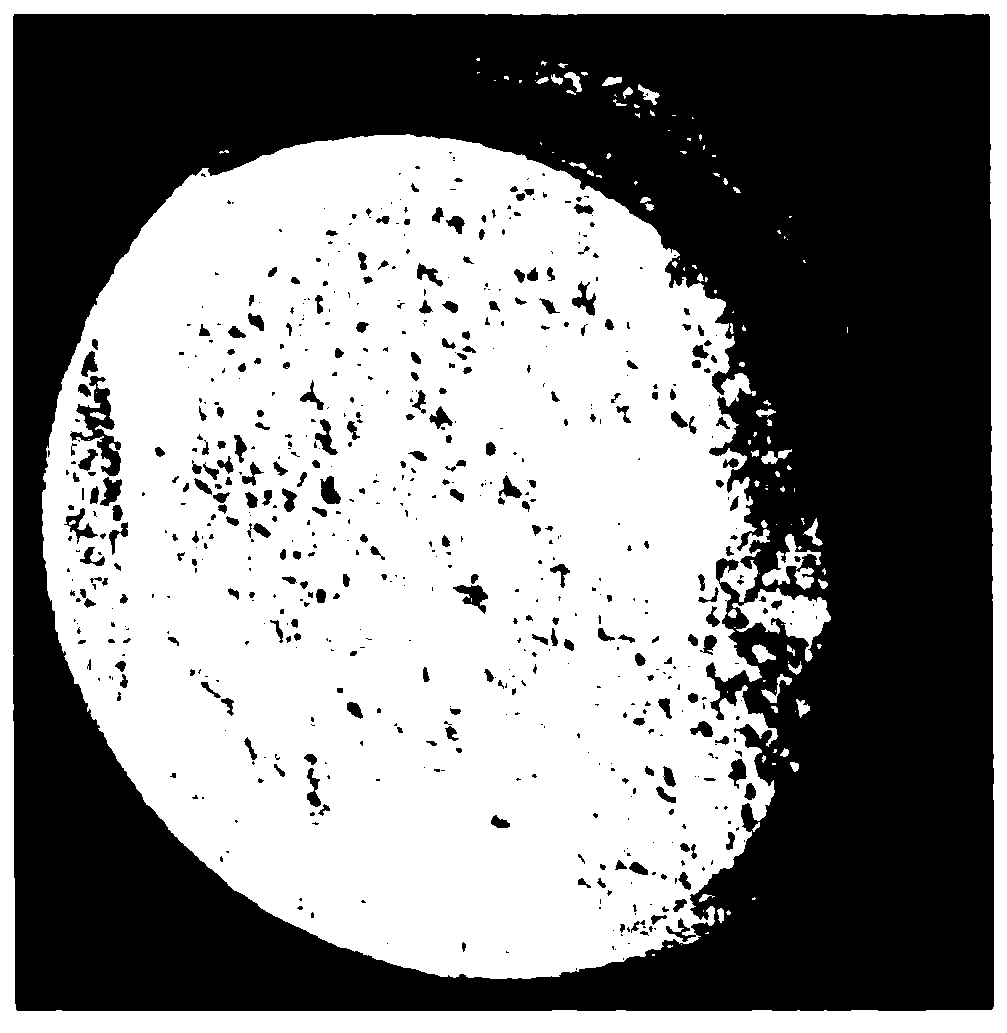

[0051] Pork bones were heated at 130° C. for 3 hours at two atmospheres. Remove the stripped bone marrow (step 1). Then, 5 g (sample 1), 0.5 g (sample 2), 0.05 g (sample 3), and 0.025 g (sample 4) of NaHCO were added to 2.5 g of the sample and 50 mL of pure water. 3 , heated at 45° C. under atmospheric pressure for 48 hours (step 2). After that, wash with water and dry at 60°C for 2 hours ( figure 1 ). The sample was pulverized into a powder ( figure 2 ). Using this as the material of the present invention, the following evaluations were performed. As a comparison, a sample (sample α) obtained by performing only step 1 and then drying and pulverizing, and commercially available hydroxyapatite were used.

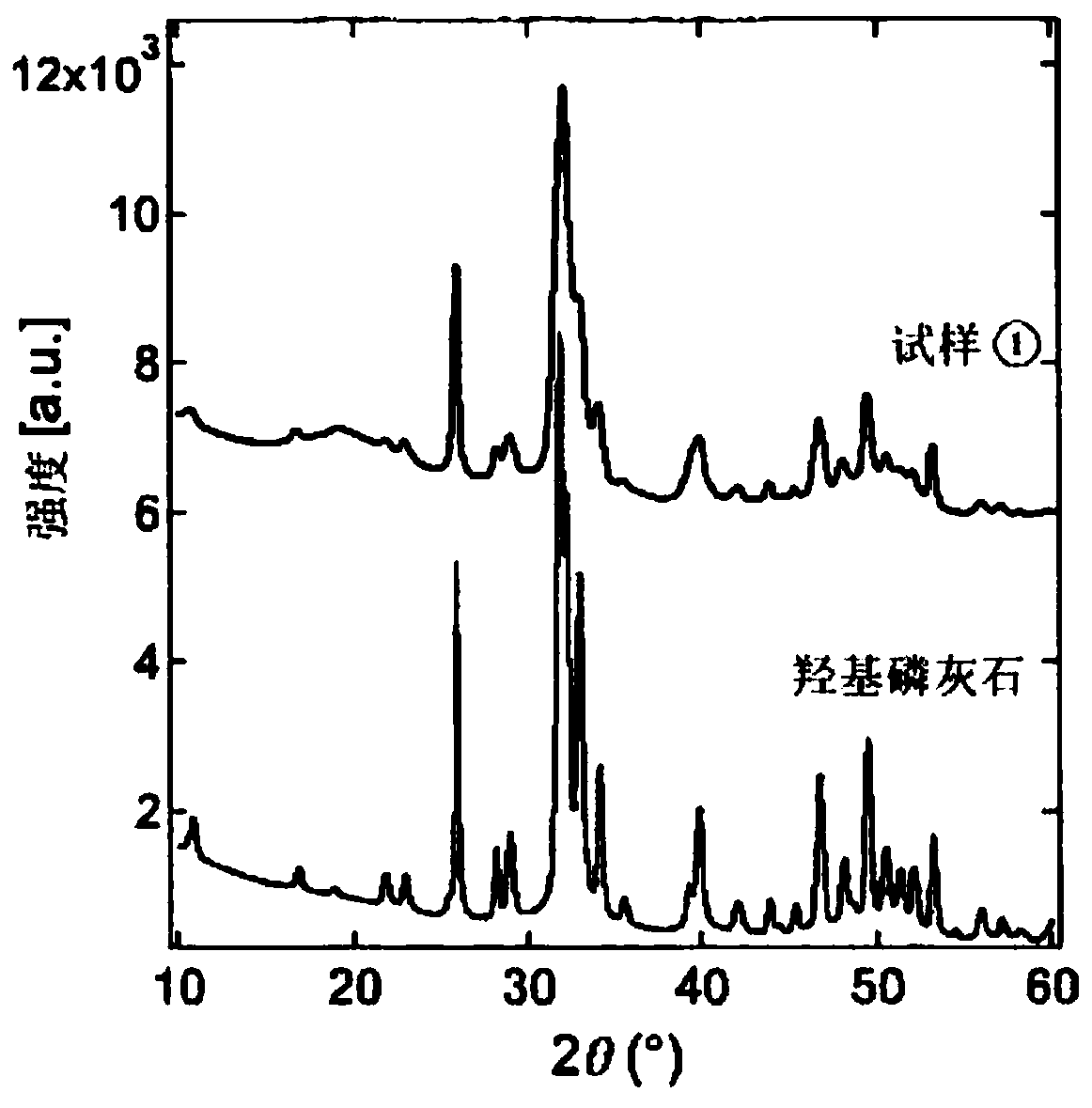

[0052] Confirmed by powder X-ray diffraction measurement: the material of the present invention obtains the same hexagonal crystal system (P6 3 / m) crystal structure ( image 3 ). The broad background ...

Embodiment 2

[0067] (Material production and physical property evaluation)

[0068] The introduction of carbonic acid was evaluated using various carbonates. Pork bones were heated at 130° C. for 3 hours at two atmospheres. Remove the stripped bone marrow (step 1). Afterwards, each 5 g of ammonium carbonate ((NH 4 ) 2 CO 3 ), sodium carbonate (Na 2 CO 3 ), potassium bicarbonate (KHCO 3 ), heated at 45° C. and atmospheric pressure for 48 hours (step 2). Thereafter, it was washed with water and dried at 60° C. for 2 hours. This sample was pulverized until it became powdery.

[0069] As a result of measuring the absorption spectrum by infrared absorption spectroscopy, it was confirmed that in the samples made of each carbonate, an increase in the intensity of the peak of the carbonic acid group was observed, and carbonic acid ( Figure 8 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com