Foam graphene-based metal azide compound and preparation method thereof

A technology of foamed graphene and composites, applied in the direction of metal azide composition, graphene, azide/azide/halogen azide, etc., can solve the problems of poor ignition ability and achieve low electrostatic sensitivity , strong security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

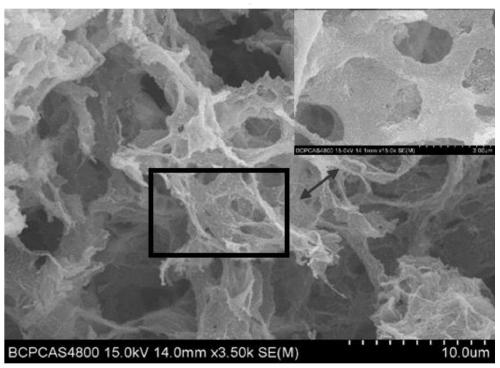

Image

Examples

Embodiment 1

[0026] Embodiment 1: raw material: copper acetate [(CH 3 COO) 2 Cu·H 2 O], sodium azide (NaN 3 ), graphene oxide (GO), stearic acid (CH 3 (CH 2 ) 16 COOH).

[0027] Main instruments and equipment: magnetic stirrer, super constant temperature water bath, measuring cylinder (5mL), glass bottle 15mL, constant temperature drying oven, hydrothermal reaction kettle, freeze dryer, tube furnace, round bottom flask, water bath.

[0028] Measure 15mL of water, add 60mg of graphene oxide, sonicate for 1h, add 0.24g of copper acetate to the spare A solution, sonicate and fully stir for 2h until it is uniformly dispersed, put the above-mentioned uniformly dispersed solution in a hydrothermal reaction kettle, and dry at constant temperature Hydrothermal reaction at 180°C in the box for 12 hours; filter and wash to obtain copper acetate and graphene composites, place the composites in liquid nitrogen, freeze-dry the frozen solids to obtain foamed graphene / copper acetate A for use; dry ...

Embodiment 2

[0029] Embodiment 2: raw material: nano copper powder (Cu), sodium azide (NaN 3 ), graphene oxide, stearic acid (CH 3 (CH 2 ) 16 COOH).

[0030] Main instruments and equipment: magnetic stirrer, super constant temperature water bath, measuring cylinder (5mL), glass bottle 15mL, constant temperature drying oven, hydrothermal reaction kettle, freeze dryer, tube furnace, round bottom flask, water bath.

[0031] Measure 13mL of water, add 60mg of graphene oxide, ultrasonic for 1h, weigh 0.4g of nano-copper powder, add 2mL of water and ultrasonically stir for 30min, slowly drop the graphene oxide solution into the stirring nano-copper dispersion, stir fully to make It is evenly dispersed, put the above-mentioned uniformly dispersed solution in a hydrothermal reaction kettle, and conduct a hydrothermal reaction in a constant temperature drying oven at 180°C for 12 hours; obtain a composite gel of graphene oxide, copper and its oxide, and place the composite in In liquid nitrogen...

Embodiment 3

[0032] Embodiment 3: raw material: nano lead oxide (PbO), sodium azide (NaN 3 ), graphene oxide, stearic acid (CH 3 (CH 2 ) 16 COOH).

[0033] Main instruments and equipment: magnetic stirrer, super constant temperature water bath, measuring cylinder (5mL), glass bottle 15mL, constant temperature drying oven, hydrothermal reaction kettle, freeze dryer, tube furnace, round bottom flask, water bath.

[0034] Measure 13mL of water, add 40mg of graphene oxide, ultrasonic for 1h, weigh 0.4g of nano-lead oxide, add 2mL of water and ultrasonically stir for 30min, slowly drop the graphene oxide solution into the stirring nano-lead oxide dispersion, stir fully Make it uniformly dispersed, put the above-mentioned uniformly dispersed solution in a hydrothermal reaction kettle, and conduct a hydrothermal reaction in a constant temperature drying oven at 180°C for 12 hours; obtain a composite gel of graphene oxide, lead oxide and its oxide, and combine The object is placed in liquid nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com