Porous azide/high explosive micro-explosion sequence film and preparation method thereof

A high-energy explosive, azide technology, applied in metal azide compositions, explosives processing equipment, explosives, etc., can solve the problems of incompatibility with MEMS technology, complicated operation, prominent safety problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A 0.10 mol / L CL-20 solution was prepared with ethyl acetate as a solvent, and the CL-20 solution was spin-coated on the porous CuN 3 Primer film, controlled spin coating speed of 50r / min, CL-20 and CuN 3 The mass ratio of CL-20 was 0.98. After the solvent was volatilized, CL-20 was recrystallized in the porous framework to obtain porous CuN 3 / CL-20 Micro-Explosive Sequence Film.

Embodiment 2

[0040] A 0.15 mol / L CL-20 solution was prepared with ethyl acetate as a solvent, and the CL-20 solution was spin-coated on the porous CuN 3 Primer film, controlled spin coating speed of 100r / min, CL-20 and CuN 3 The mass ratio of CL-20 was 1.53. After the solvent was volatilized, CL-20 recrystallized inside the porous framework to obtain porous CuN 3 / CL-20 Micro-Explosive Sequence Film.

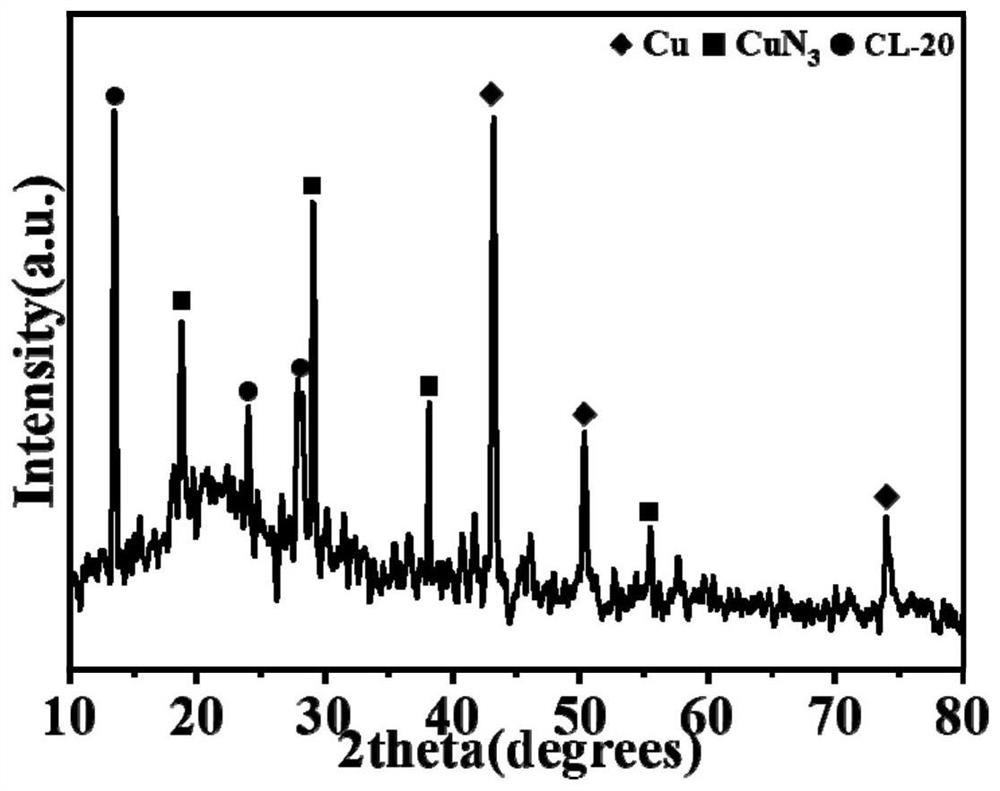

[0041] figure 1 Porous CuN prepared for Example 2 3 The XRD pattern of the / CL-20 micro-explosive sequence film shows that the composition of the micro-explosive sequence film is Cu, CuN 3 and CL-20.

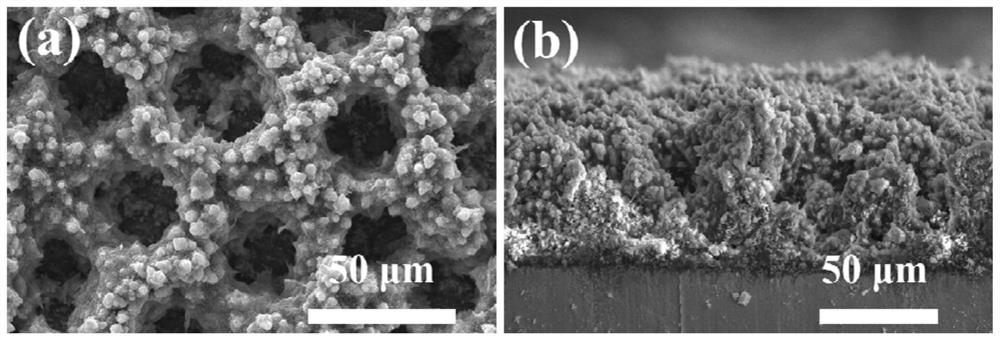

[0042] figure 2 Porous CuN prepared for Example 2 3 SEM images of / CL-20 micro-explosion sequence film, (a) is a top view, (b) is a cross-sectional view, the porous structure is clearly visible at this time, and the CL-20 crystals are filled in the porous CuN 3 in the interstitial space.

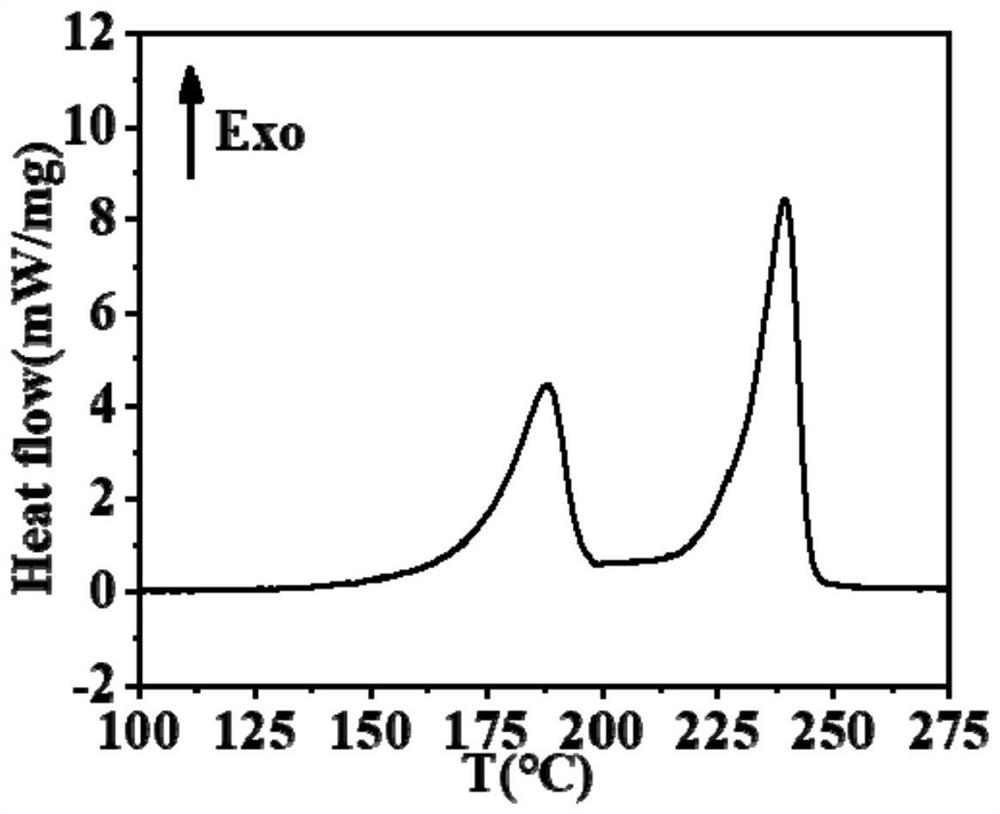

[0043] image 3 Porous CuN prepared for Example 2 3 DSC image of / CL-20 microexplosive sequent...

Embodiment 3

[0045] A 0.30 mol / L CL-20 solution was prepared with ethyl acetate as a solvent, and the CL-20 solution was spin-coated on the porous CuN 3 Primer film, controlled spin coating speed of 100r / min, CL-20 and CuN 3 The mass ratio of CL-20 was 3.0. After the solvent was volatilized, CL-20 recrystallized inside the porous framework to obtain porous CuN 3 / CL-20 Micro-Explosive Sequence Film.

[0046] Figure 4 Porous CuN prepared for Example 3 3 SEM images of / CL-20 micro-explosion sequence film, (a) is a top view, (b) is a cross-sectional view, at this time CL-20 fills the pore wall of the porous structure, CuN 3 The dendrite gaps were filled with CL-20.

[0047] Figure 5 Porous CuN prepared for Example 3 3 DSC image of / CL-20 microexplosive sequential film. It shows that the explosion sequence film has two exothermic peaks, the first peak corresponds to CuN 3 The thermal decomposition of CL-20, the peak temperature is about 190℃, the exothermic heat of the decomposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com