Preparation method of loxoprofen

A new method and intermediate technology, applied in the field of preparation of loxoprofen, can solve the problems of long compound synthesis route, poor compound activity, low reaction conversion rate, etc., and achieve simple and easy-to-obtain starting materials, weak corrosiveness, color shallow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a kind of preparation method of loxoprofen, and concrete steps are as follows:

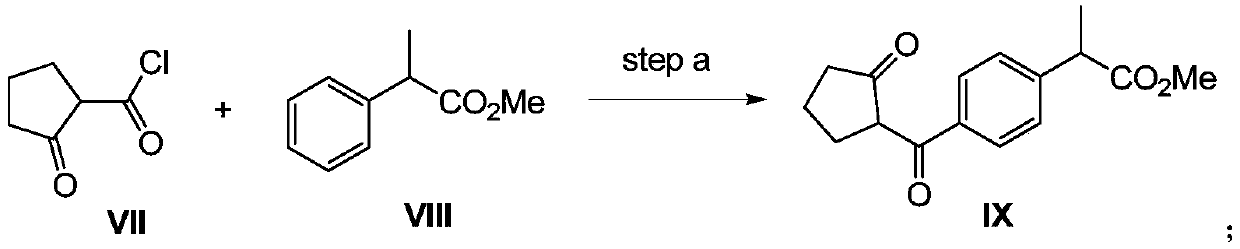

[0040] Step 1: Synthesis of intermediate (IX):

[0041] Add 55g of compound (Ⅷ), 300mL of dichloromethane and 70g of anhydrous aluminum trichloride to the reaction flask, control the internal temperature to about 0°C, and slowly dissolve 53.5g of compound (Ⅶ) prepared according to Example 4 into 50mL of dichloromethane Add the solution dropwise into the reaction flask; then rise to 40°C and stir for 12 hours until no obvious gas is released; after cooling, slowly add 750mL of 4N hydrochloric acid aqueous solution into the reaction system at a temperature of 0-5°C; then raise the temperature to 25°C, Continue to stir for 1 h; separate the organic phase; extract the aqueous phase once with 100 mL of dichloromethane, and combine the organic phases; wash the organic phase with 500 mL of saturated aqueous sodium bicarbonate solution and 500 mL of water successively, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com