Continuous electric heating rotary furnace and process for preparing lithium manganate through rotary furnace

A rotary furnace and continuous technology, which is applied in the field of continuous electric heating rotary furnace, can solve the problems of limited production efficiency of production enterprises, poor performance of heating and heat preservation, and insufficient heat preservation structure, and achieve shortening of calcination time, heating and heat preservation. Effects of performance improvement and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

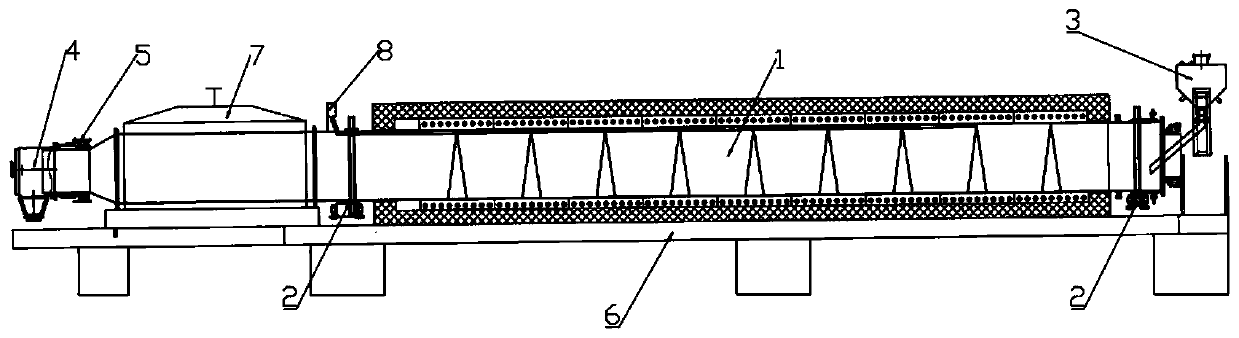

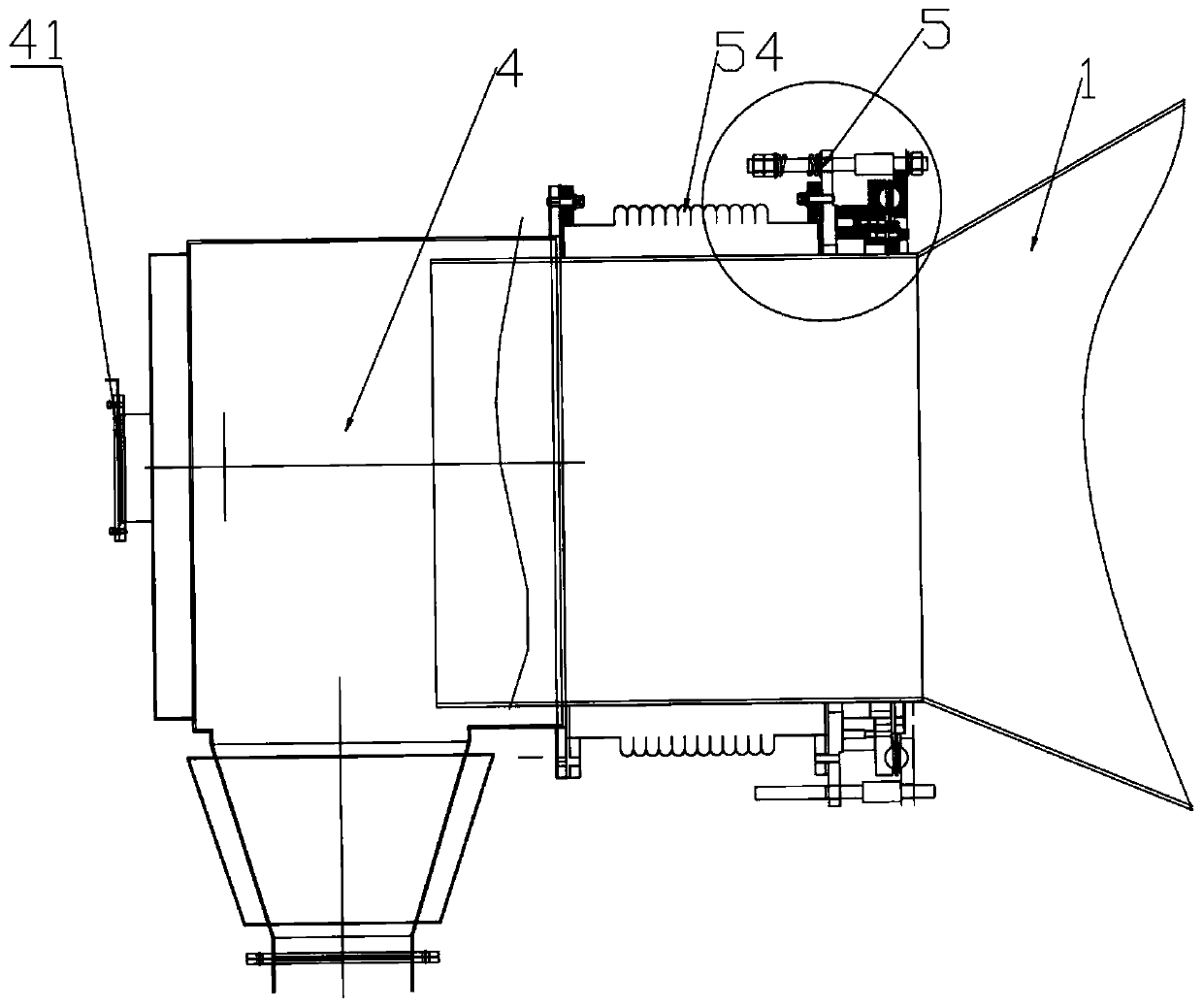

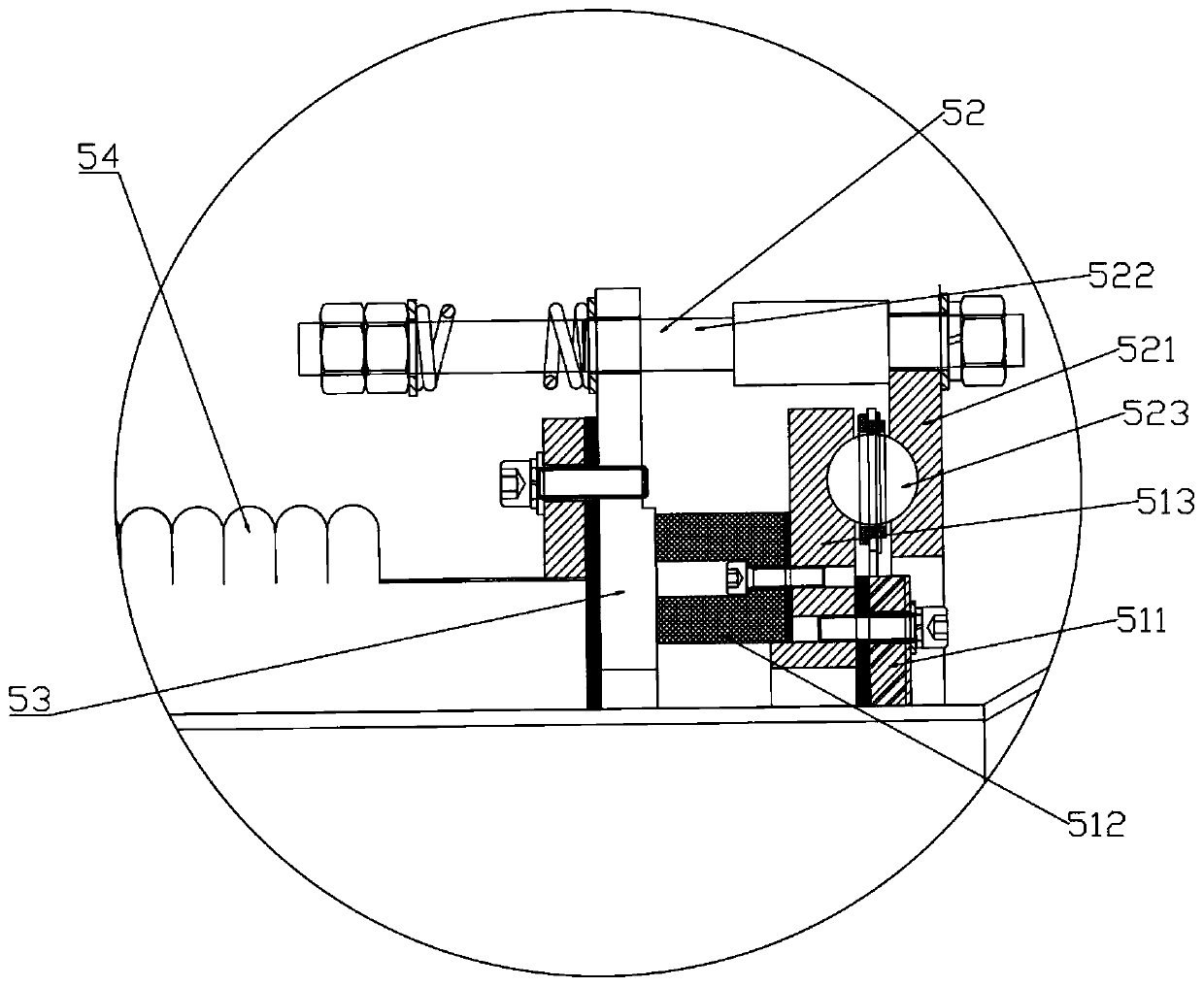

[0080] This embodiment provides a continuous electric heating rotary furnace, such as Figure 1-3 Shown, including:

[0081] The furnace tube part 1 (specifically, the furnace tube part 1 is arranged on the furnace bottom beam 6) has a furnace heating zone inside, and the furnace tube part 1 as a whole is at a certain angle with the horizontal plane to allow the furnace tube part 1 to enter The material end is higher than the discharge end; the furnace heating is divided into several temperature zones (in a specific embodiment, from the front end to the back end of the furnace tube part 1 is divided into 9 temperature zones, and finally a slow cooling Zone), each of the temperature zones is independently controlled and heated, and the heat insulation layer of the furnace tube section 1 is made of high-temperature ceramic fiber material; the furnace roof of the furnace tube section 1 adopts a multi-section integrated block structure, and each section of the furnace roof is integrat...

Embodiment 2

[0148] This embodiment provides a method for calcining lithium manganate. The lithium manganate precursor is placed in the electric rotary furnace provided in Example 1, air is introduced at a flow rate of 30L / min, and the rotation speed of the furnace tube is controlled to 2 revolutions / Hours, heat the furnace temperature to 150 degrees in 15 minutes, calcine at 150 degrees for 60 minutes, then use 45 minutes to increase the temperature in the furnace from 150 degrees to 600 degrees, then keep the temperature at 600 degrees for 90 minutes, and then use 14 minutes to The temperature in the furnace is increased from 600 degrees to 740 degrees, and it is calcined at 740 degrees for 300 minutes. After the calcination is completed, the temperature is naturally cooled to room temperature to obtain a commercial lithium manganate product.

Embodiment 3

[0150] This embodiment provides a method for calcining lithium manganate. The lithium manganate precursor is placed in the electric rotary furnace provided in Example 1, air is introduced at a flow rate of 40L / min, and the rotation speed of the furnace tube is controlled at 6 rpm. Hours, heat the furnace temperature to 150 degrees in 10 minutes, calcine at 150 degrees for 40 minutes, then use 30 minutes to increase the temperature in the furnace from 150 degrees to 600 degrees, then keep the temperature at 600 degrees for 60 minutes, and then take 9 minutes to The temperature in the furnace is increased from 600 degrees to 740 degrees, and it is calcined at 740 degrees for 200 minutes. After the calcination is completed, the temperature is naturally cooled to room temperature to obtain a commercial lithium manganate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com