HEMT device based on Fin-like side wall modulation of transconductance compensation method and preparation method of HEMT device

A compensation method and side wall technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as deterioration of device frequency characteristics, large device etching damage, large gate parasitic capacitance, etc., to meet high-frequency High linearity application requirements, meeting the application requirements of high voltage and high linearity, and the effect of large current output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

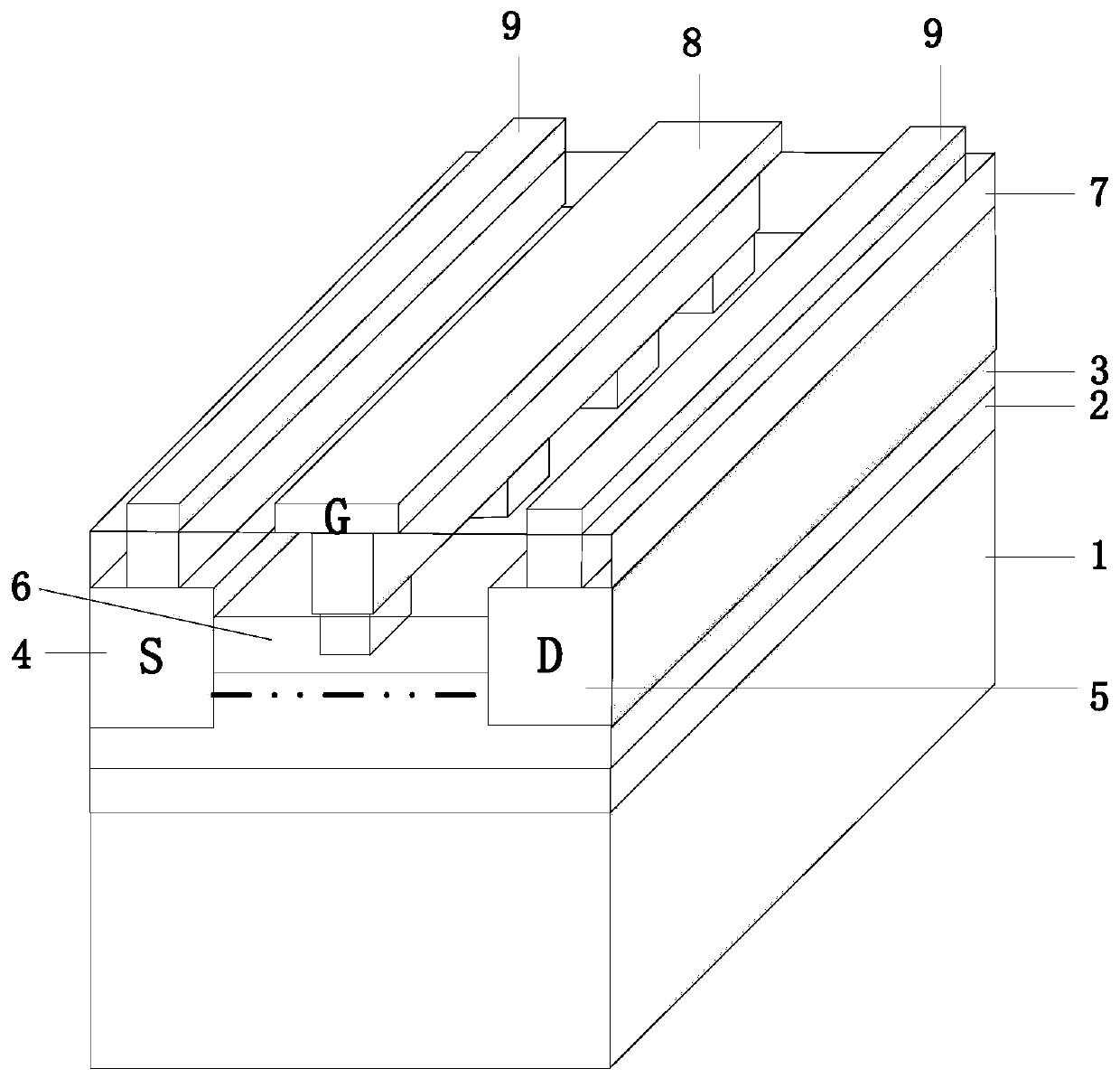

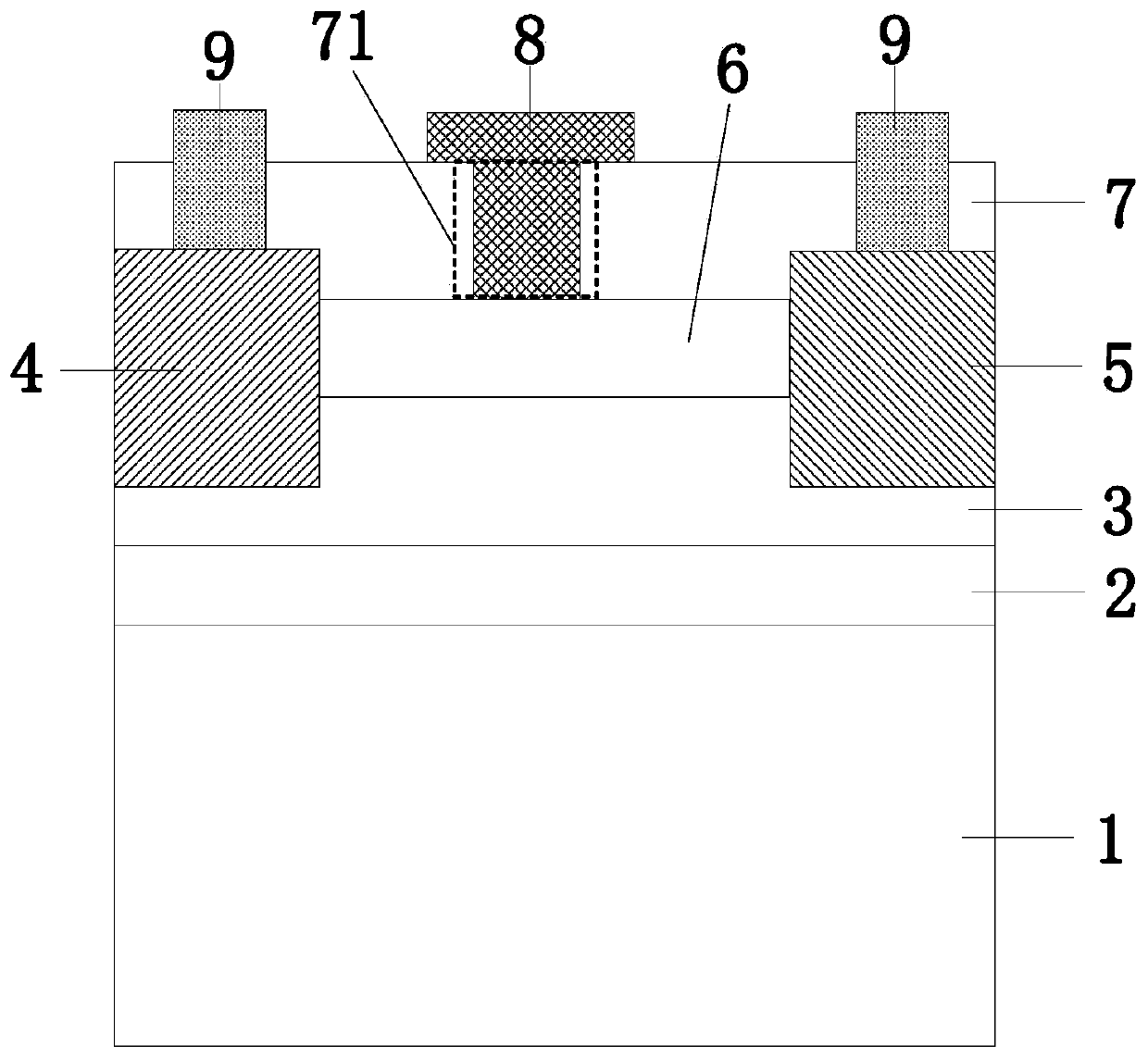

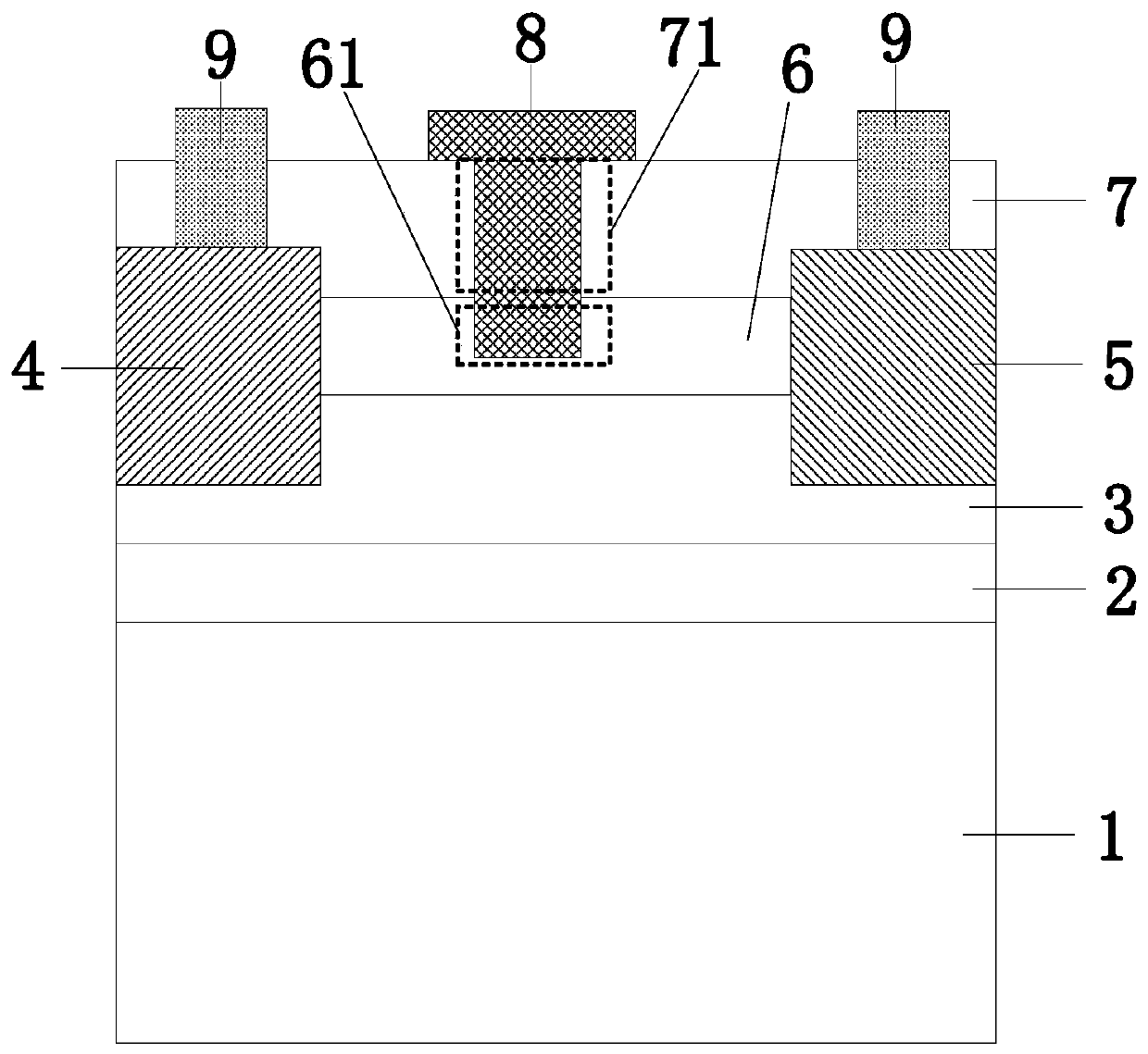

[0055] See figure 1 , figure 1 A schematic structural diagram of a Fin-like spacer modulation HEMT device based on a transconductance compensation method provided by an embodiment of the present invention, the HEMT device includes: a substrate layer 1, an insertion layer 2, a buffer layer 3, a source electrode 4, and a drain electrode 5. Barrier layer 6, passivation layer 7, gate electrode 8 and metal interconnection layer 9.

[0056] Specifically, the substrate layer 1 includes one or more of sapphire, SiC or Si. The insertion layer 2 is located on the substrate layer 1, and its material may be AlN. The buffer layer 3 is located on the insertion layer 2, and its material may be GaN. The source electrode 4 is located at one end of the buffer layer 3, and the drain electrode 5 is located at the other end of the buffer layer 3; the material of the source electrode 4 and the drain electrode 5 is ohmic metal, which is Ti / Al / Ni / Au from bottom to top. The barrier layer 6 is loca...

Embodiment 2

[0083] On the basis of Example 1, please refer to Figure 5 and Figure 6a-Figure 6h , Figure 5 A schematic flow chart of a method for manufacturing a Fin-like spacer-modulated HEMT device based on a transconductance compensation method provided by an embodiment of the present invention, Figure 6a-Figure 6h It is a schematic diagram of a method for manufacturing a Fin-like spacer-modulated HEMT device based on a transconductance compensation method provided by an embodiment of the present invention. The preparation method comprises steps:

[0084] S1 , growing an insertion layer 2 , a buffer layer 3 and a barrier layer 6 sequentially on the substrate layer 1 . See Figure 6a .

[0085] In this embodiment, an epitaxial substrate comprising a substrate layer 1, an AlN insertion layer 2, a GaN buffer layer 3, and an AlGaN barrier layer 6 from bottom to top is used as the initial material.

[0086] S2, prepare the source electrode 4 at one end on the buffer layer 3, and pr...

Embodiment 3

[0160] On the basis of Embodiment 1 and Embodiment 2, please refer to Figure 7 , Figure 7 It is a schematic flowchart of another fabrication method of a Fin-like spacer-modulated HEMT device based on a transconductance compensation method provided by an embodiment of the present invention. The preparation method comprises steps:

[0161] S1 , growing an insertion layer 2 , a buffer layer 3 and a barrier layer 6 sequentially on the substrate layer 1 .

[0162] S2 , prepare the source electrode 4 at one end on the buffer layer 3 , and prepare the drain electrode 5 at the other end on the buffer layer 3 .

[0163] S3, photoetching the electrical isolation region of the active region on the AlGaN barrier layer 3, and manufacturing the electrical isolation of the active region of the device by using an ICP process.

[0164] S4 , growing a passivation layer 7 on the barrier layer 6 , the source electrode 4 and the drain electrode 5 in the active region.

[0165] S5 , etching t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com