Anti-electrolysis high-low voltage composite micro pulse power supply

A pulsed power supply, high and low voltage technology, applied in electric pulse generator circuits, energy storage components to generate pulses, electrical components, etc., can solve the problems of difficult to meet advanced pulsed power supply, low power utilization, poor discharge stability, etc., to improve The effect of power utilization, reliability increase, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

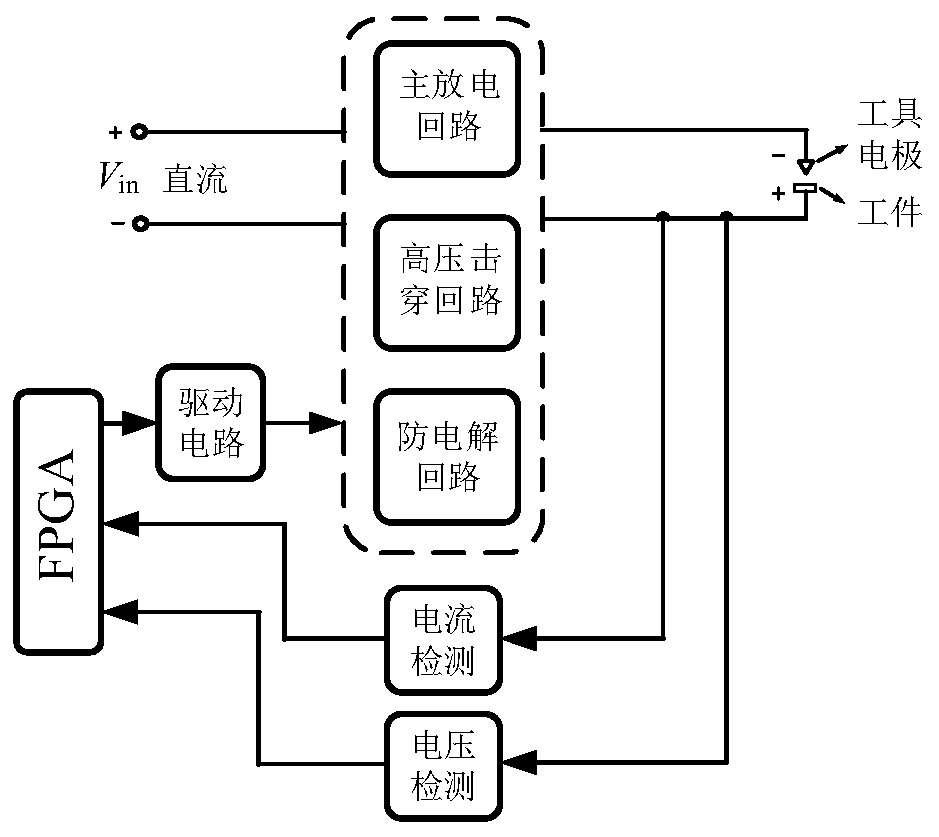

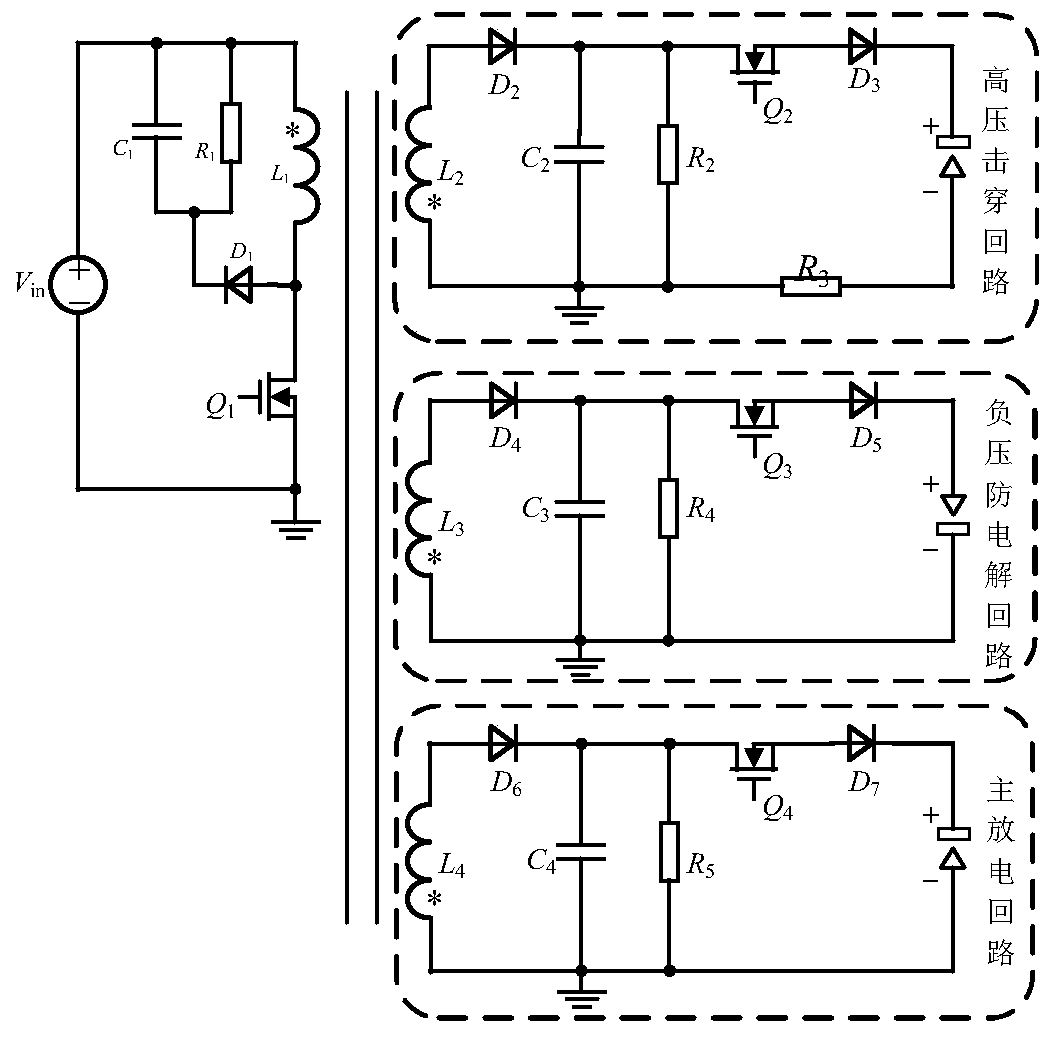

[0025] Such as Figure 1-2 As shown, the anti-electrolysis high-voltage and low-voltage composite micro-pulse power supply of the present invention includes a DC power supply, a pulse power supply main circuit composed of a primary circuit, a flyback high-voltage breakdown circuit, a micro-pulse power supply main discharge circuit, and a negative pressure anti-electrolysis circuit. circuit, drive circuit, and current and voltage detection circuit, wherein the DC power supply is the primary circuit of the main circuit of the pulse power supply, the main discharge circuit of the micro pulse power supply, and the negative pressure anti-electrolysis circuit; the main discharge circuit of the pulse power supply, the high-voltage breakdown circuit, the anti- The output of the electrolysis circuit is connected to the gap load for workpiece pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com