Method for preparing mineral wool fibers from leaching residues of hydrometallurgy laterite-nickel ore and application of mineral wool fibers

A technology of mineral wool fiber and laterite nickel ore, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of uneven quality of mineral wool products, high viscosity of slag, uneven mixing of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

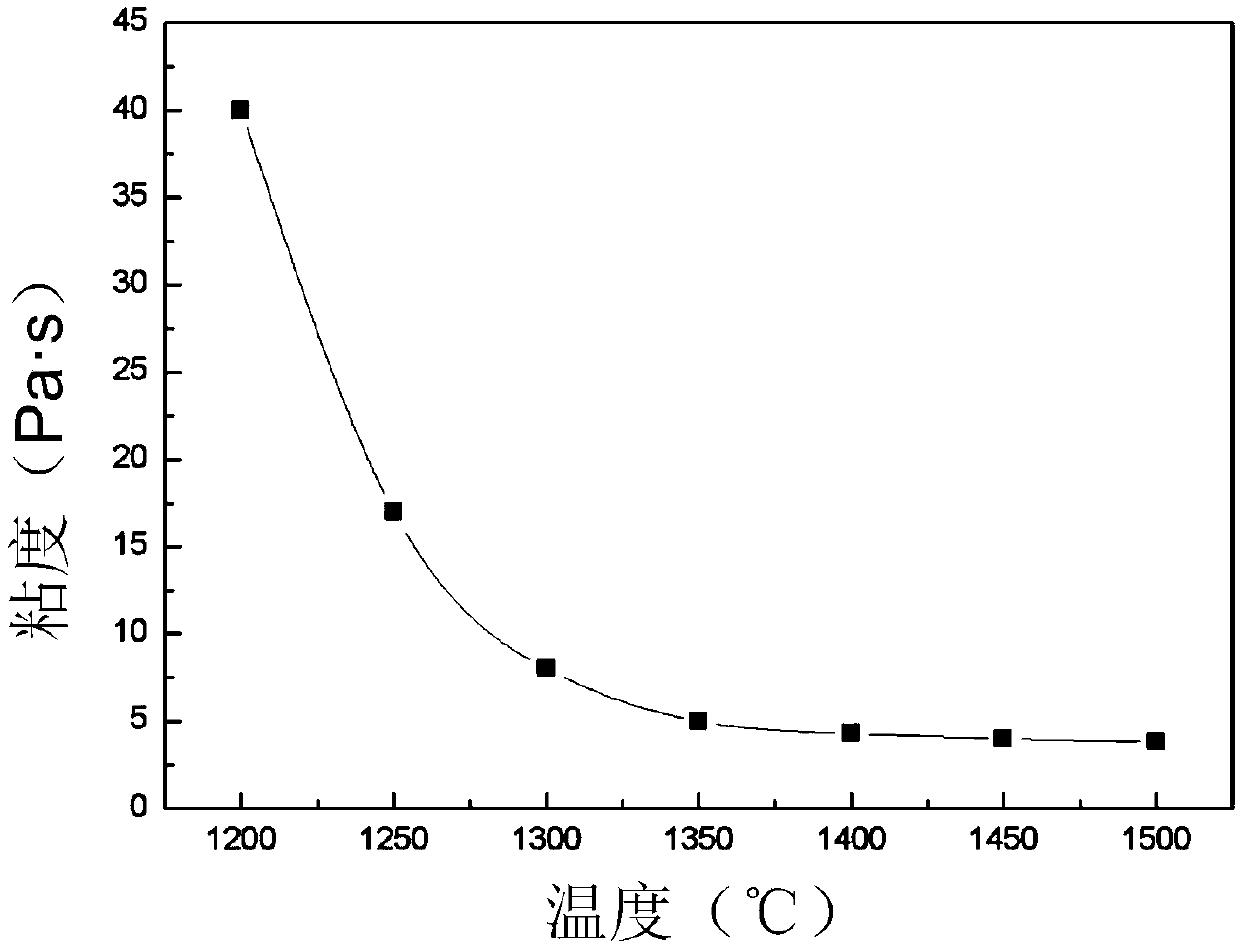

[0028] Use concentrated hydrochloric acid to leach laterite nickel ore leaching slag (serpentine-type laterite nickel ore or limonite-type laterite nickel ore) as raw material, and the size of the leaching slag powder is 0.1-20000 μm. The leaching slag is not prepared, and the leaching slag is directly placed in high temperature Furnace for melting. When the temperature of the high-temperature furnace is raised to 1500°C, it is kept warm for two hours, and the furnace hole is opened to flow the molten slurry to the rollers of the four-roller centrifuge, and then centrifuged at a high speed to form cotton. While centrifuging into cotton, resin glue is sprayed on the mineral wool, and then the cotton is collected by the cotton collector, conveyed to the pleating machine and pressurized by the conveyor, and then sent to the curing furnace for curing and molding, and finally cut The finished mineral wool board.

Embodiment 2

[0030] The leaching slag of laterite nickel ore leached with concentrated sulfuric acid (serpentine-type laterite nickel ore or limonite-type laterite nickel ore) is used as raw material, and the leaching slag is not prepared, and the leaching slag is directly put into a high-temperature furnace. Set the temperature of the high-temperature furnace to 1800°C, and as the temperature of the material increases gradually, the material begins to melt. After the material is melted, it flows out of the furnace body with the guide groove to the roller of the four-roller centrifuge under the action of gravity, and the material is continuously added for continuous production. The melted slurry flows to the rollers of the four-roller centrifuge, and is centrifuged at a high speed to become cotton. While centrifuging into cotton, resin glue is sprayed on the mineral wool, and then the cotton is collected by the cotton collector, conveyed to the pleating machine and pressurized by the conve...

Embodiment 3

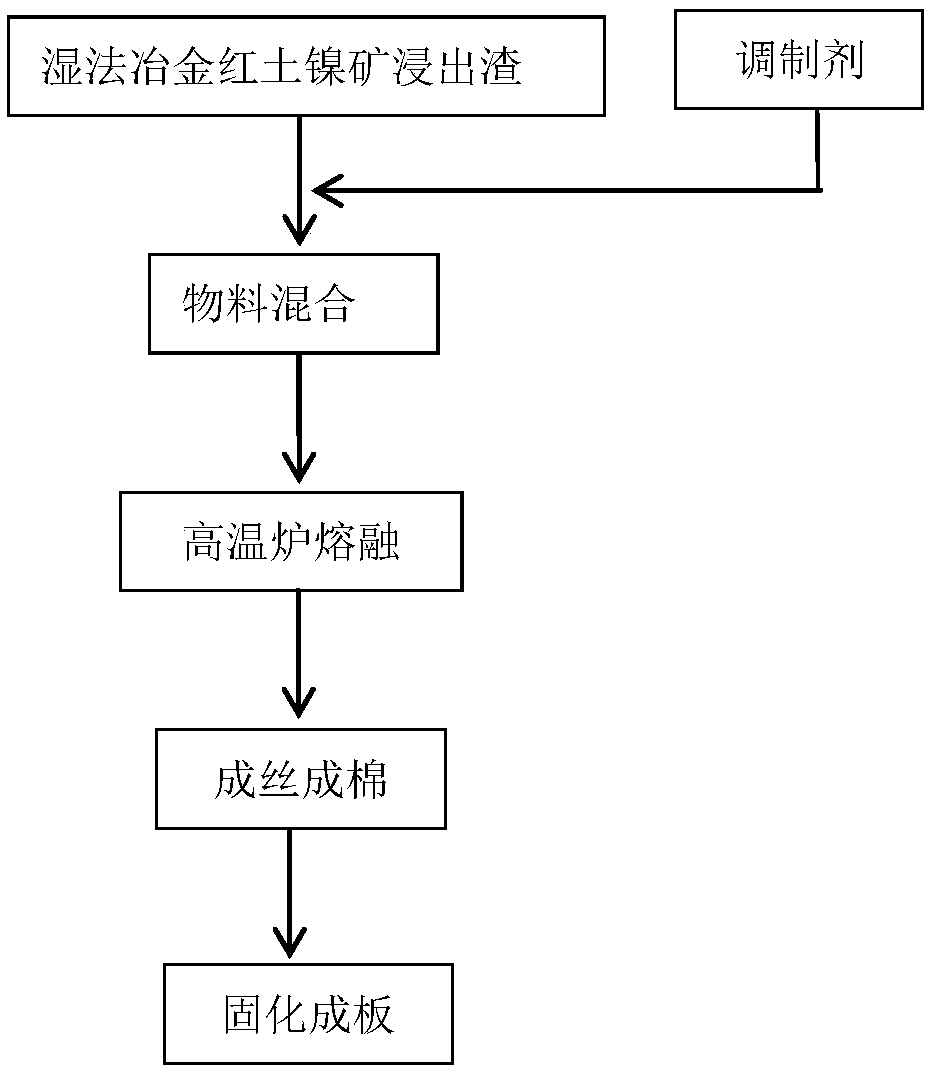

[0032] like figure 1 As shown, the leaching slag of laterite nickel ore leached with concentrated hydrochloric acid (serpentine-type laterite-nickel ore or limonite-type laterite-nickel ore) is used as the basic raw material, mixed with bauxite for preparation, and the size of the preparation agent and leaching slag powder is 0.1 -20000μm, so that the acidity coefficient of the mixed material is 1.2. Add 10%-50% bauxite into the leaching slag, and then use a mixer to stir. After the materials are mixed evenly, after a certain treatment, the materials are put into a high-temperature furnace for melting, and the melting temperature is 1600°C. After the material is melted, under the action of gravity, it flows out of the furnace body with the material guide groove to the nozzle of the injection equipment, and the material is continuously added for continuous production. The melted slurry flows to the rollers of the four-roller centrifuge, and is centrifuged at a high speed to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com