Preparation method of flexible kettle body and flexible kettle

A pot body, flexible technology, applied in the field of water equipment, can solve the problems of easy to be scratched, short service life, etc., achieve excellent antibacterial ability, meet the needs of use, and save storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a flexible kettle body, comprising the following steps:

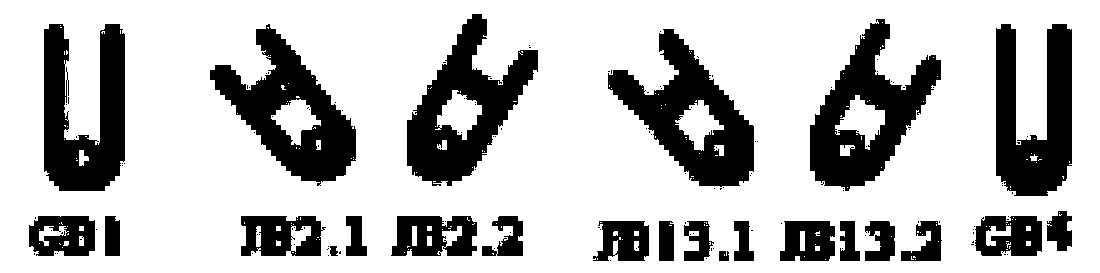

[0028] Step 1: using a double needle bed double jacquard warp knitting machine to weave a pot body blank 2 with a base cloth 1 using metal fibers;

[0029] Step 2: Cut out the kettle body blank 2 from the kettle body blank 2 with the base cloth 1 prepared in step 1;

[0030] Step 3: Coat a layer of flexible PDMS composite material on the position corresponding to the kettle wall of the blank of the kettle body prepared in step 2, and obtain a flexible kettle body after cooling.

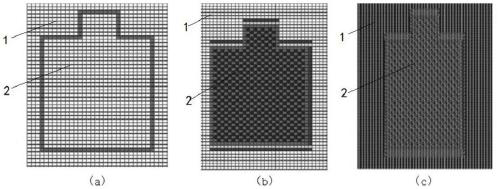

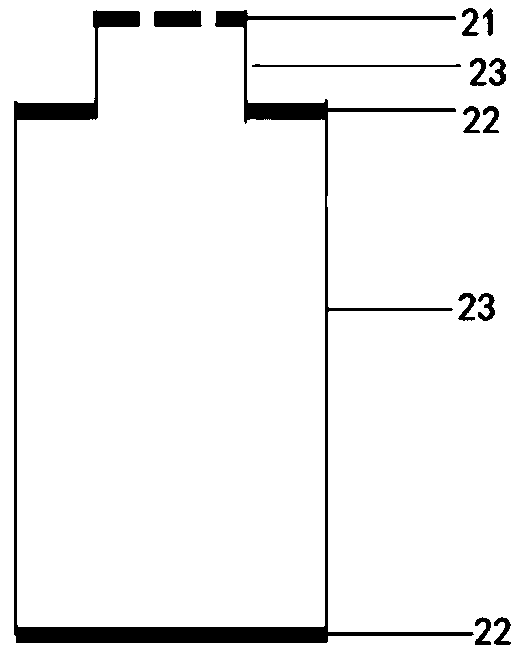

[0031] Among them, such as Figure 1-2 As shown, the middle part of the upper end of the blank of the kettle body is closed, and the upper end of the closed mouth is woven with a filter screen and constitutes the mouth of the blank of the kettle body ( figure 2 In the first line 21), where, figure 1 The middle a is the pattern artisan's picture, figure 1 b is the process design drawing...

Embodiment 2

[0041] Such as Figure 4 As shown, the present embodiment provides a flexible kettle, including a kettle lid and a flexible kettle body 3 prepared by the method described in Example 1. The mouth of the flexible kettle body 3 is provided with an outer ring as a circle Shaped hard ring 41, the outer wall of the hard ring 41 is provided with external threads, the pot lid 42 is a groove cover, and its inner groove wall is provided with external threads on the hard ring 41 Matching internal threads, the pot cover 42 is threadedly connected with the hard ring 41 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Single fiber strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com