Plant enzyme odor-removing composite bio-enzyme formaldehyde-removing preparation and preparation method thereof

A compound biological enzyme and plant enzyme technology, applied in the field of plant enzyme deodorization compound biological enzyme aldehyde removal preparation and its preparation, can solve the problems of easy rebound, inability to remove peculiar smell, reduce volatile peculiar smell and formaldehyde, etc., and achieve Not easy to rebound, easy to popularize, and reduce the effect of pollution stock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

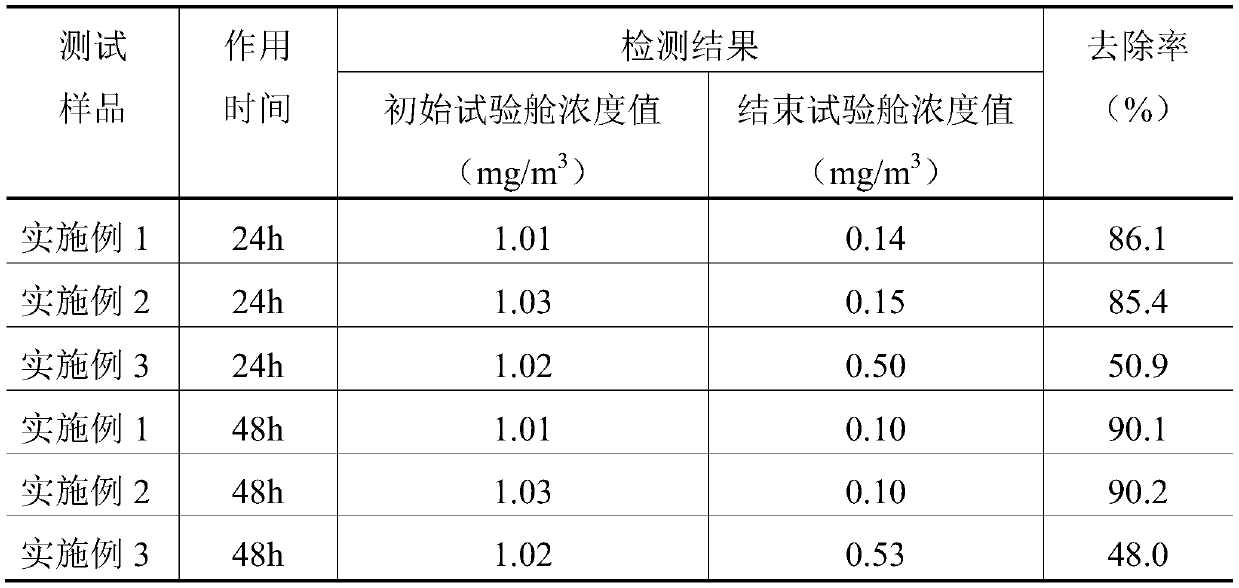

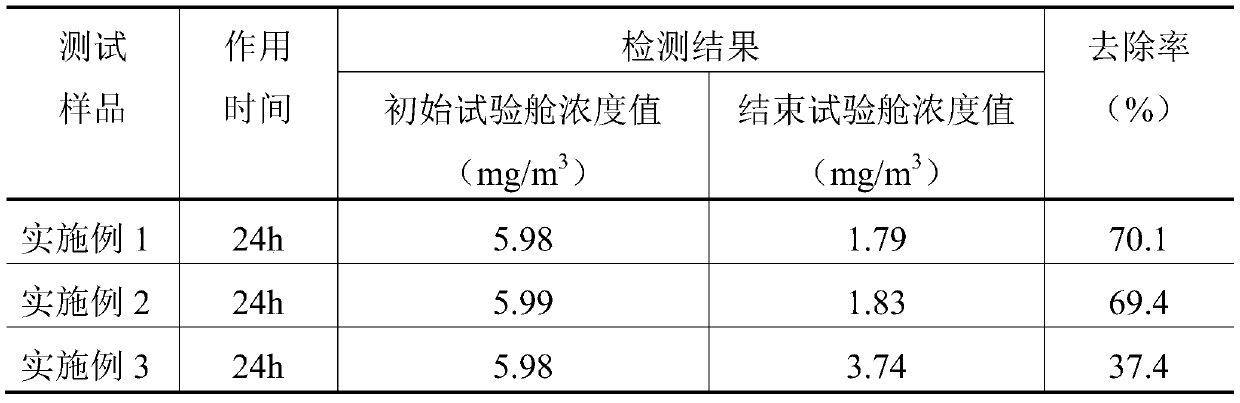

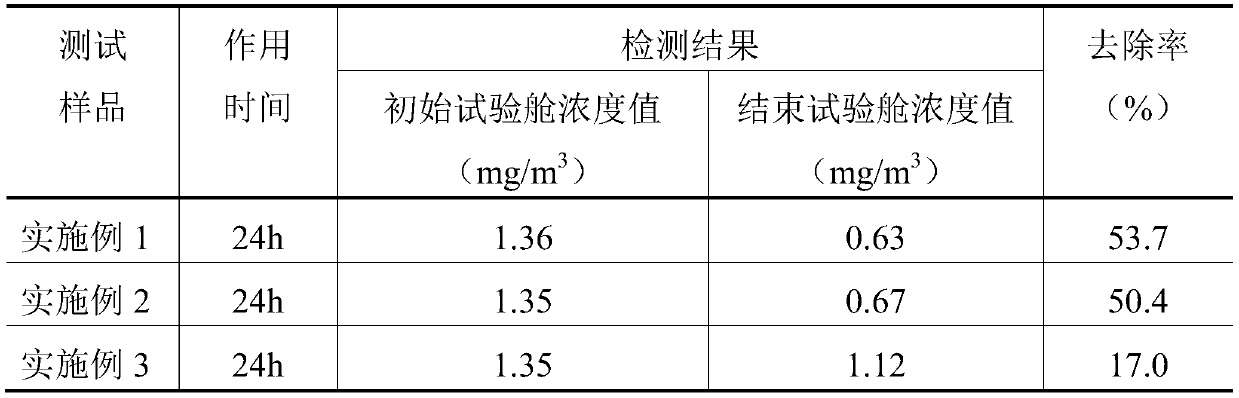

Examples

Embodiment 1

[0030] A plant enzyme odor-removing compound biological enzyme aldehyde-removing preparation, including 45 parts of plant enzyme fermentation liquid, 50 parts of pure plant extract, 4 parts of biological protease, 1 part of fog enhancer, 2 parts of stabilizer, 8 parts of moisturizer, 50 parts of ionized water;

[0031] Wherein, the plant enzyme fermentation liquid is prepared by fermentation of the following components in parts by weight: 15 parts of saponins, 12 parts of grapefruit peels, 12 parts of orange peels, 12 parts of tea leaves, 12 parts of lemon leaves, 12 parts of wormwood, and 15 parts of ginger 10 parts of alcohol, 10 parts of white sugar, and 100 parts of deionized water.

[0032] Wherein, the tea leaves in the plant enzyme fermentation liquid are obtained by drying and reclaiming the wet tea leaves after soaking.

[0033] Wherein, the pure plant extract is a natural plant extract of trees or flowers, and the natural plant is one or more of mugwort leaves, euca...

Embodiment 2

[0041] The preparation method of the mixed preparation of formaldehyde-removing and odor-removing microorganisms described in this example is exactly the same as that of Example 1, the difference lies in the different ratios of raw material components. In this example, the raw material components are as follows:

[0042] Plant enzyme deodorization complex bio-enzyme de-aldehyde preparation, including 60 parts of plant enzyme fermentation liquid, 6 parts of biological protease, 8 parts of pure plant extract, 1 part of fog enhancer, 2 parts of stabilizer, 8 parts of humectant, 60 parts of deionized water share;

[0043] Wherein, the plant enzyme fermentation liquid is prepared by fermentation of the following components in parts by weight: 15 parts of saponins, 12 parts of grapefruit peels, 12 parts of orange peels, 12 parts of tea leaves, 12 parts of lemon leaves, 12 parts of wormwood, and 15 parts of ginger , 10 parts of wine with an alcohol content of 12% to 15%, 35 parts of ...

Embodiment 3

[0047] The preparation method of the mixed preparation of formaldehyde-removing and odor-removing microorganisms described in this example is exactly the same as that of Example 1, except that the raw material components are different. In this example, no plant enzyme fermentation liquid is added. In this example, The raw material components are as follows:

[0048] Odor-removing compound biological enzyme aldehyde-removing preparation, including 33 parts of pure plant extract, 4 parts of biological protease, 1 part of fog enhancer, 2 parts of stabilizer, 5 parts of humectant, and 100 parts of deionized water;

[0049] Wherein, the pure plant extract is a natural plant extract of trees or flowers, and the natural plant is one or more of mugwort leaves, eucalyptus, grapefruit peel, orange peel, lemon, mint or honeysuckle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com