Wood superheated steam drying and heat treatment integrated device and using method

A wood drying and superheated steam technology, applied in wood heat treatment, wood drying, wood treatment and other directions, can solve the problems of long wind speed circulation path, uneven heat transfer, long drying cycle, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

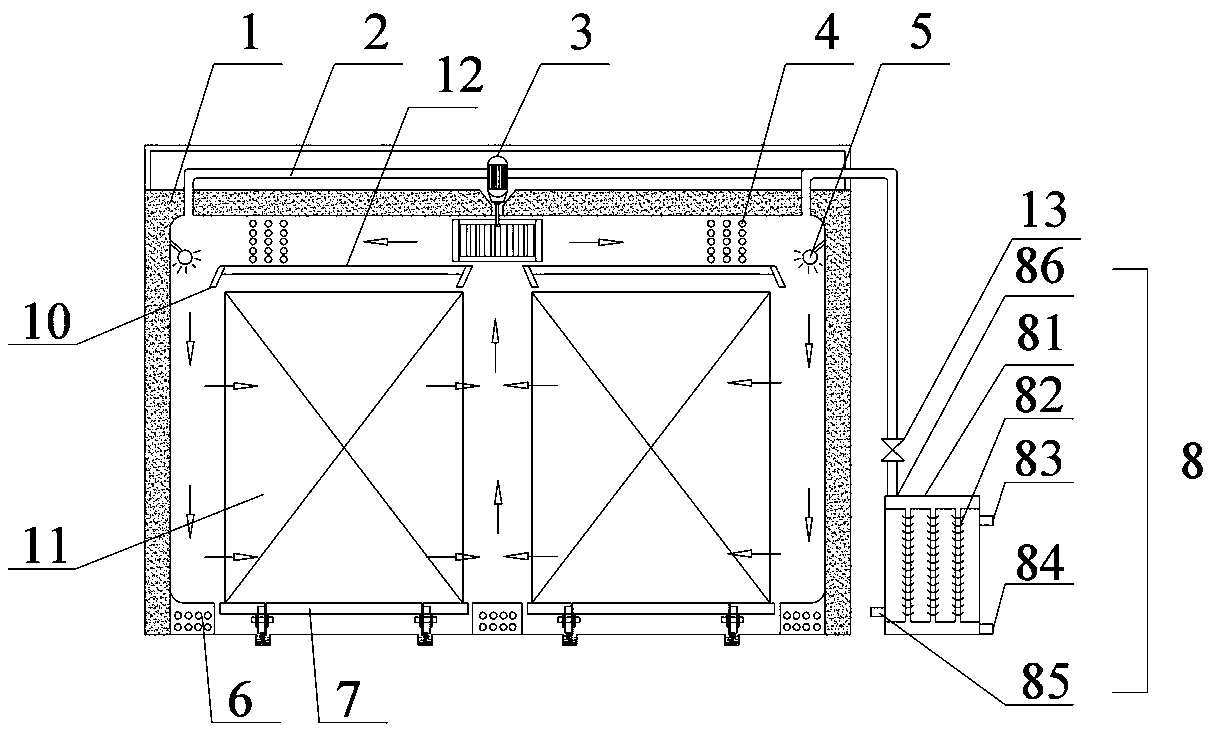

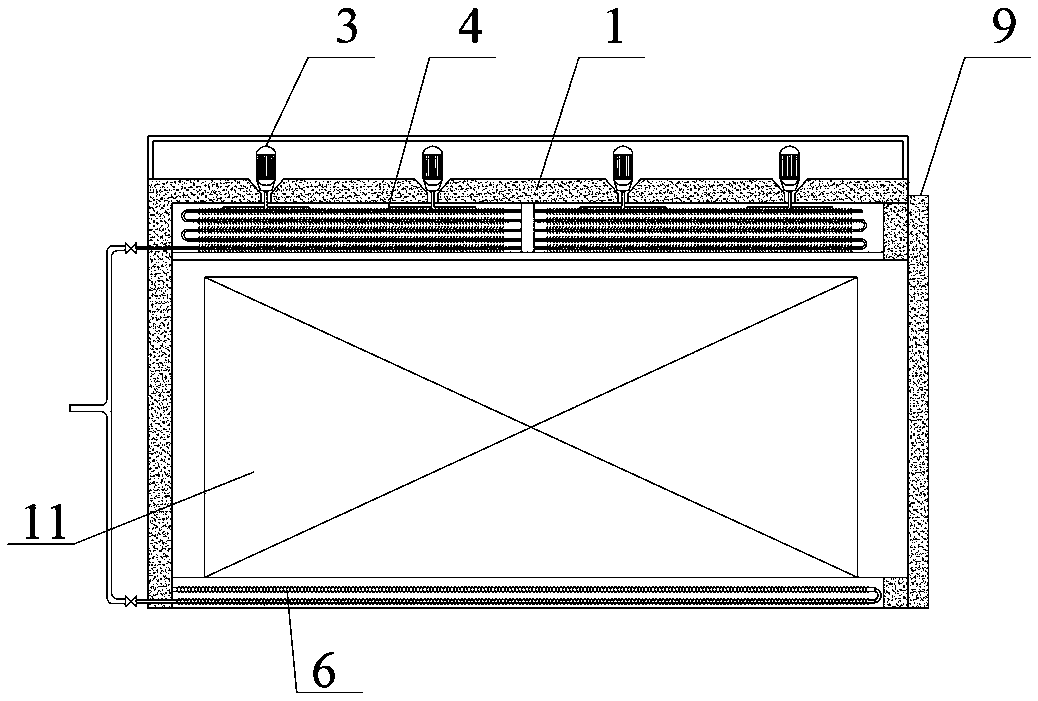

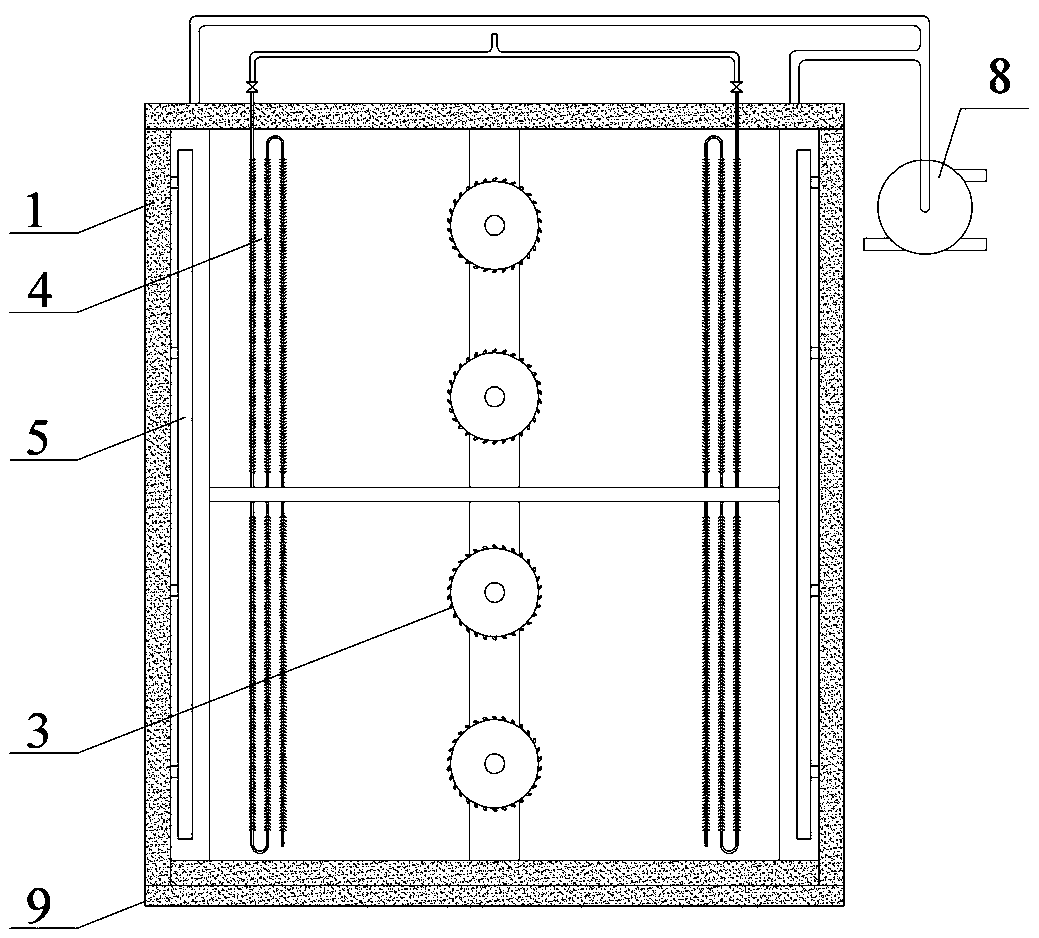

[0037] Such as Figures 1 to 3 As shown, an integrated device for wood superheated steam drying and heat treatment in this embodiment includes a kiln body 1, a fan assembly 3, a heater assembly 4, a steam spray assembly 5 and a partition 12. The kiln body 1 is provided with multiple A wood drying area 11 arranged at intervals, a plurality of heater assemblies 4 are arranged on the top of the wood drying area 11, a plurality of fan assemblies 3 are positioned above the gap between adjacent wood drying areas 11 and the air outlet of the fan assembly 3 faces the heating The device assembly 4, the partition 12 is horizontally arranged between the wood drying area 11 and the heater assembly 4, the two sides of the partition 12 are spaced apart from the two side walls of the kiln body 1, and the two sides of the partition 12 are provided with a downward slope. The air deflector 10 is provided, the top two sides of the kiln body 1 are provided with exhaust outlets 2, and the steam sp...

Embodiment 2

[0053] The integrated device adopted in this embodiment is the same.

[0054] The use method of the integrated device of wood superheated steam drying and heat treatment in this embodiment comprises the following steps:

[0055] S1: Wood enters the drying kiln: the height of the wood pile is 2m, the width of the wood pile is 2m, the thickness of the section of the spacer is 25mm, and the width of the section of the spacer is 30mm, divided into two piles, and the wood pile enters through the kiln door 9 relying on the slide rail 7 Wood drying and heat treatment kiln, and placed in the wood drying area 11, close the kiln door 9.

[0056] S2: High-humidity preheating: Turn on the fan assembly 3 and the heater assembly 4, the fan assembly 3 enters the air through the axial direction, and when the gas flows through the impeller, it changes to the radial direction, forming a two-way medium channel in the kiln body 1. Use gradient heating method to dry and preheat the wood, first ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com