Separation method of C5 olefin mixture

A separation method, the technology of carbon pentaolefins, applied in the field of chemical engineering, can solve the problems of low adsorption capacity, selectivity and adsorption capacity at the same time, and achieve large pore volume, high separation selectivity and adsorption capacity, and synthetic The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

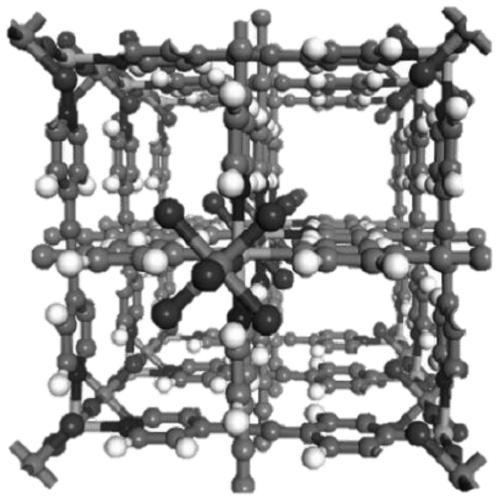

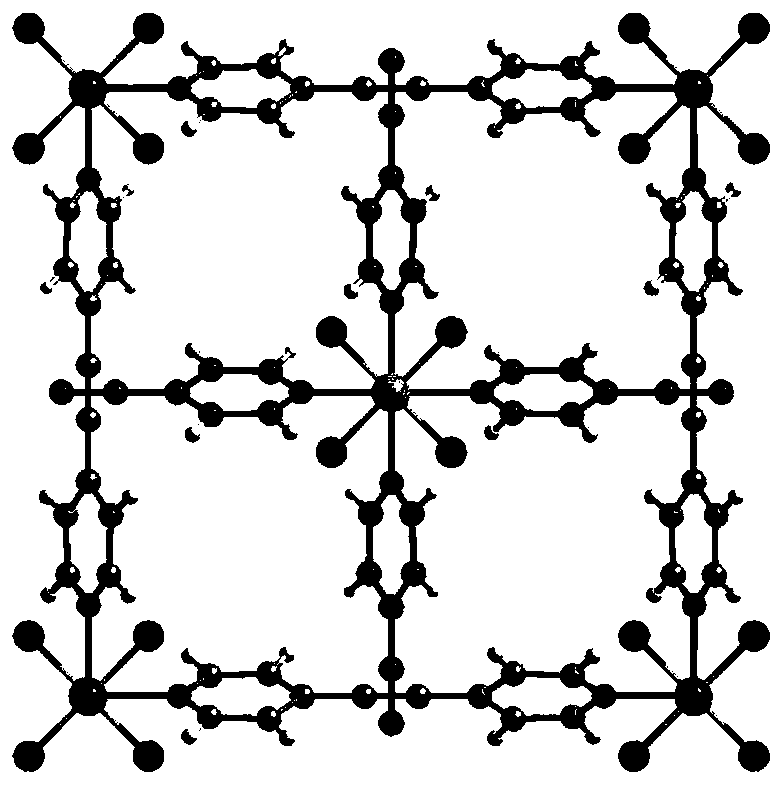

[0053] 1.0mmol Ni(BF 4 ) 2 , 1.0mmol (NH4) 2 TiF 6 Dissolve in 10mL of anhydrous methanol, dissolve 1.5mmol of 1,2-dipyridylacetylene in 10mL of methanol, and mix and stir the two solutions at 20-85°C. After the reaction is completed, the product is obtained by suction filtration. The product is washed with methanol for 3 to 4 times and then soaked in methanol for activation for 1 day. Vacuum activation at 85°C for 24 hours yielded a fluorine-containing anion hybrid porous material TIFSIX-2-Ni-i with flexible functions.

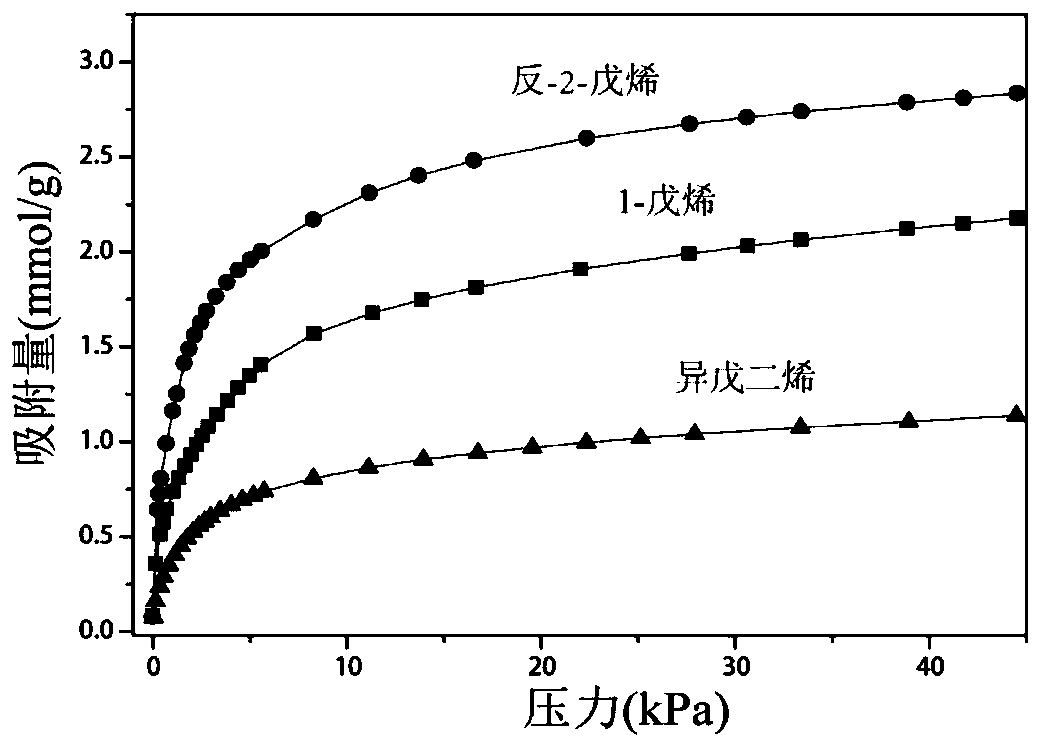

[0054] Measure the one-component adsorption isotherm of TIFSIX-2-Ni-i at 298K for 1-pentene, trans-2-pentene, and isoprene. The results are as follows image 3 As shown, it is shown that this material can achieve the separation of the above-mentioned C5 olefin components.

Embodiment 2

[0056] 1.0mmol Cu(BF 4 ) 2 · H2O, 1.0mmol (NH 4 ) 2 GeF 6 Dissolve 1.5mmol of 1,2-dipyridineacetylene in 10mL of methanol, mix and stir at 65°C for 24h, filter the material with suction, wash with methanol for 3-4 times, and activate in vacuum at room temperature for 24h to obtain Fluorine-containing anion hybrid porous material GeFSIX-2-Cu-i with flexible functions.

[0057] Measure the one-component adsorption isotherm of GeFSIX-2-Cu-i at 298K for 1-pentene, trans-2-pentene, and isoprene. The results are as follows Figure 4 As shown, it is shown that this material can achieve the separation of the above-mentioned C5 olefin components.

Embodiment 3

[0059] 1.0mmol Cu(BF 4 ) 2 · H2O, 1.0mmol (NH 4 ) 2 SiF 6 Dissolve in 10mL of water, dissolve 1.5mmol of 1,2-dipyridineacetylene in 10mL of methanol, mix and stir the two at 85°C for 12h, filter the material with suction, wash with methanol for 3-4 times, activate in vacuum at 65°C for 24h, A fluorine-containing anion hybrid porous material SIFSIX-2-Cu-i with flexible functions was obtained.

[0060] Measure the one-component adsorption isotherm of SIFSIX-2-Cu-i at 298K for 1-pentene, trans-2-pentene and isoprene, the results are as follows Figure 5 As shown, it is shown that this material can achieve the separation of the above-mentioned C5 olefin components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com