Reversed phase chromatography stationary phase and preparation method and application thereof

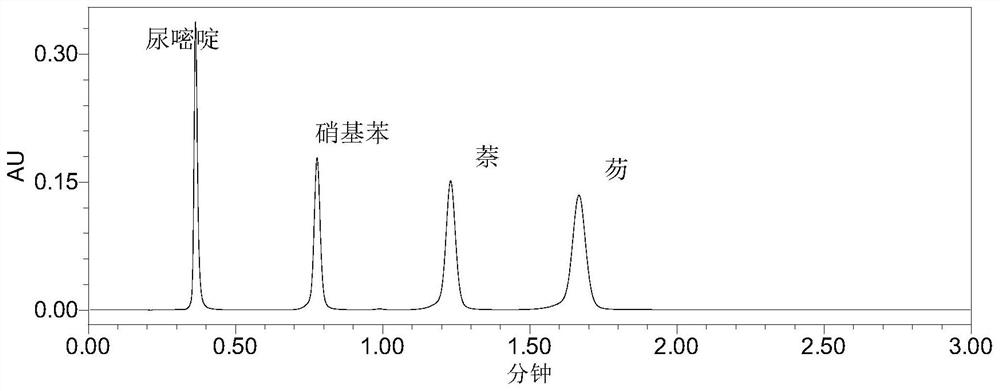

A reversed-phase chromatography and stationary phase technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problem of not meeting all sample separation requirements, and achieve simple and reliable preparation process, industrialization, and good separation. selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

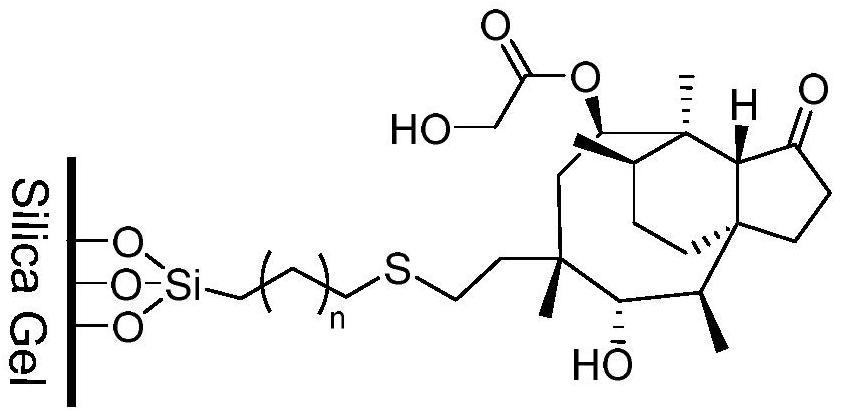

[0029] The invention provides a kind of preparation method of reverse phase chromatography stationary phase, comprises the following steps:

[0030] a. Silica gel pretreatment: Silica gel is added to a strong acid solution with a concentration of 20-40wt%, heated to reflux and stirred for 1-48 hours, filtered, washed with water until pH=6-7, and the obtained solid is stored in a drying oven at 100-160°C Dry for 8 to 24 hours to obtain acidified silica gel;

[0031] Wherein, the dosage of the strong acid solution is 2-20 mL per gram of silica gel; the strong acid solution is one of hydrochloric acid, nitric acid and sulfuric acid.

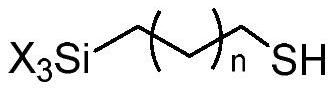

[0032] b. Synthesis of mercapto intermediates: under the protection of nitrogen or argon, add mercaptosilane coupling agent and acidified silica gel in an organic solvent, react at 20-130°C for 1-48 hours, filter, and use methanol, tetrahydrofuran, washing with methanol, and vacuum-drying the obtained solid in a drying oven at 40-80°C for 8-24 hour...

Embodiment 1

[0048] Add 10g of silica gel to a 250mL flask, add 100mL of 20wt% nitric acid solution, heat to reflux and stir for 2 hours, filter, wash with water until pH = 6-7, and dry the resulting solid in a drying oven at 160°C for 24 hours. Acidified silica gel was obtained.

[0049] Under the protection of nitrogen, add 10g of acidified silica gel, 6mL of mercaptopropyltrimethoxysilane and 60mL of xylene to a 100mL flask, react at 110°C for 16 hours, filter, and wash with methanol, tetrahydrofuran and methanol in sequence to obtain a solid Vacuum drying in a drying oven at 80° C. for 24 hours to obtain a mercaptopropyl intermediate.

[0050] Under nitrogen protection, add 10g of mercaptopropyl intermediate, 12.8g of pleuromutilin, 4.9g of azobisisobutylimidazoline hydrochloride and 100mL of methanol / water (v / v=7 / 3) into a 250mL flask The mixed solution was reacted at 60°C for 48 hours, filtered, washed with water, methanol, water, and methanol successively, and the obtained solid wa...

Embodiment 2

[0053] Add 10g of silica gel to a 250mL flask, add 100mL of 35wt% nitric acid solution, heat to reflux and stir for 2 hours, filter, wash with water until pH = 6-7, and dry the resulting solid in a drying oven at 160°C for 24 hours. Acidified silica gel was obtained.

[0054] Under the protection of nitrogen, add 10g of acidified silica gel, 12mL of mercaptohexyltrichlorosilane and 120mL of toluene into a 100mL flask, react at 160°C for 3 hours, filter, wash with methanol, tetrahydrofuran, and methanol in sequence, and the obtained solid is placed in a dry box Vacuum drying at 80°C for 24 hours gave the mercaptohexyl intermediate.

[0055] Under nitrogen protection, add 10g mercaptohexyl intermediate, 12.8g pleuromutilin, 4.9g azobisisobutylimidazoline hydrochloride and 100mL ethanol / water (v / v=7 / 3) to a 250mL flask and mix The solution was reacted at 60°C for 48 hours, filtered, washed with water, methanol, water, and methanol successively, and the obtained solid was vacuum-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com