Synthesis method and application of combustion rate regulator

A synthesis method and regulator technology, applied in chemical instruments and methods, non-explosive/non-thermal agent components, preparation of amino compounds, etc., can solve propellant production requirements, unsatisfactory process performance, and poor propellant burning rate adjustment effect Excellent and other problems, to achieve the effect of excellent burning rate process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

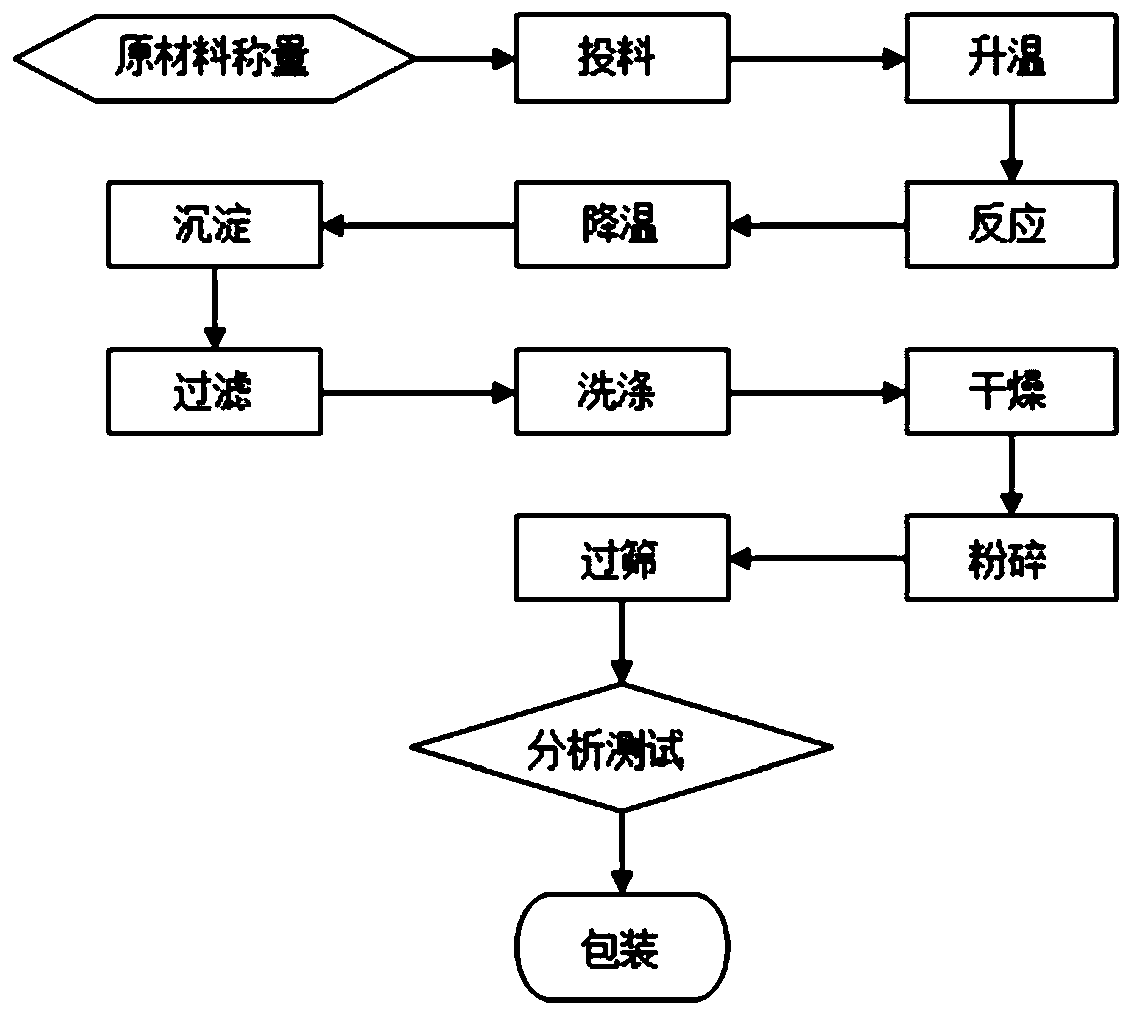

Method used

Image

Examples

Embodiment 1

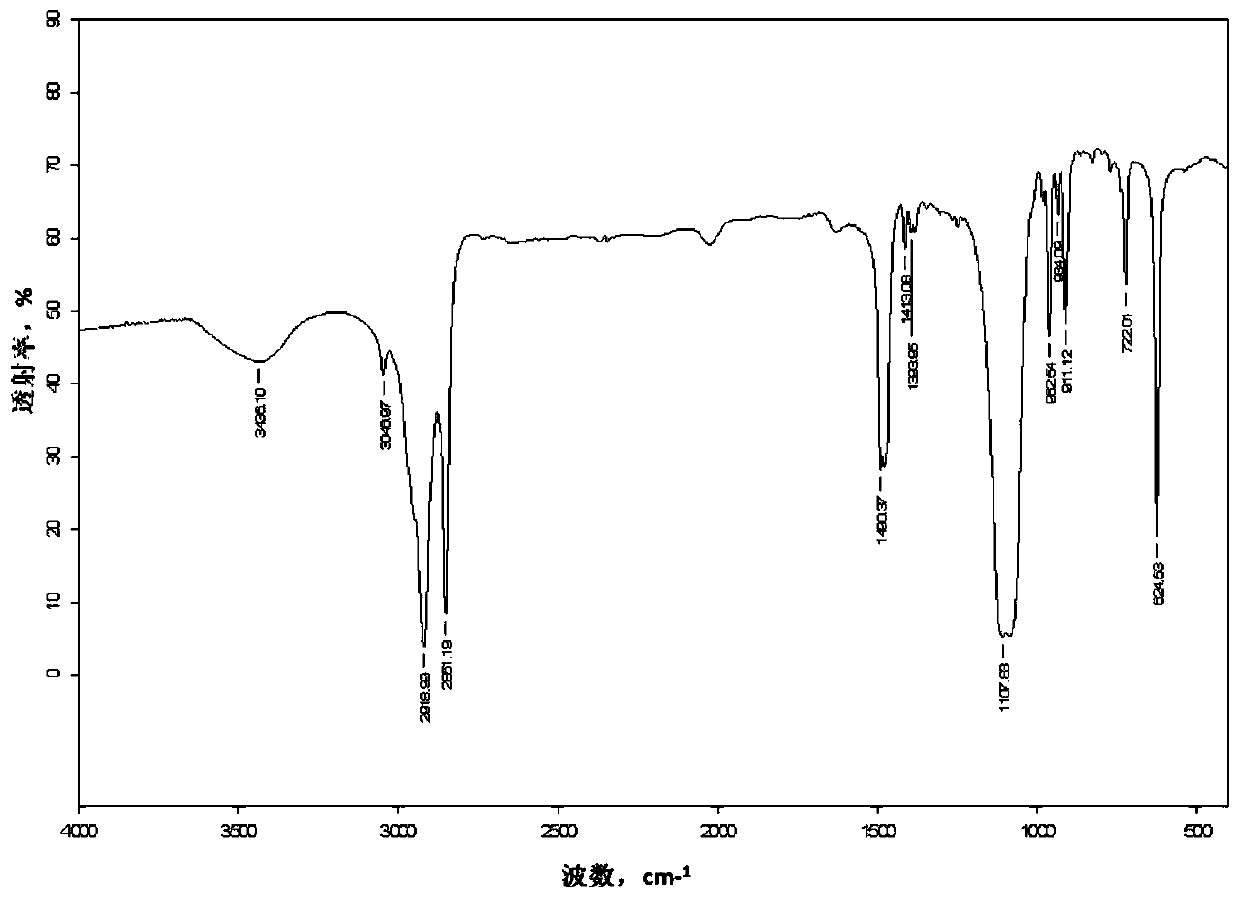

[0037] The burning rate regulator was synthesized from trimethylhexadecylammonium bromide and perchloric acid as starting materials. Weigh 5 g (0.014 mol) of trimethylhexadecyl ammonium bromide and place it in a three-necked flask. Weigh 0.8 g perchloric acid (content 70%, 0.015 mol) and dilute to 50 mL with purified water. Add 100mL of pure water into the there-necked flask, start stirring and raise the temperature to 80°C. After the raw materials are completely dissolved, add the perchloric acid solution dropwise with the addition funnel. After the addition, continue to stir for 30 minutes, stop heating, and let the solution cool down naturally. As the temperature decreased, powdery precipitates gradually appeared in the solution. After the temperature of the solution dropped to room temperature, it was filtered with a Buchner funnel, and the filter cake was rinsed with pure water until the filtrate was neutral. The filter cake was taken out and dried at 105° C. for 2 hour...

Embodiment 2

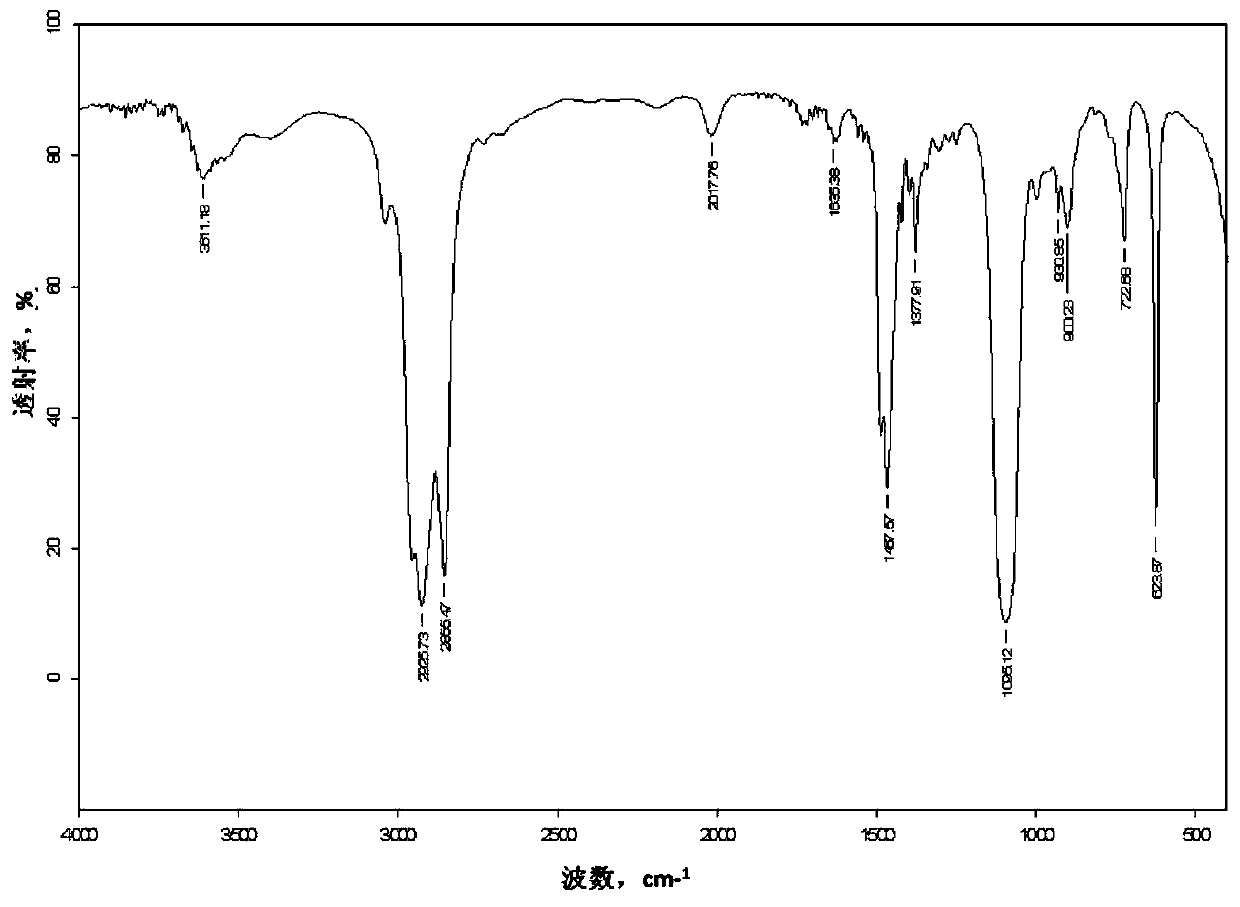

[0039] The burning rate regulator was synthesized from dimethyl dioctadecyl ammonium chloride and ammonium perchlorate as starting materials. Weigh 20 g (0.034 mol) of dimethyl dioctadecyl ammonium chloride and place it in a three-necked flask. Weigh 4.4g (0.037mol) of ammonium perchlorate and dissolve it in 50mL of purified water. Add 200mL of pure water into the three-necked flask, start stirring and raise the temperature to 60°C. After the raw materials are completely dissolved, add the ammonium perchlorate solution dropwise with the addition funnel. Stirring was continued for 30 min after the addition was complete, the heating was stopped, and the solution was allowed to cool down to room temperature naturally. Put ice cubes into the water bath to lower the temperature of the solution below 10°C. After the precipitation is precipitated, quickly filter it with a Buchner funnel, and rinse the filter cake with pure ice water until the filtrate is free of chloride ions. The ...

Embodiment 3

[0041] The burning rate regulator was synthesized from dimethyldidecyl ammonium bromide and potassium perchlorate as starting materials. Weigh 50 g (0.12 mol) of dimethyl didecyl ammonium bromide and place it in a three-necked flask. Weigh 17.9 g (0.13 mol) of potassium perchlorate and dissolve it in 400 mL of pure water. Add 400mL of pure water into the three-necked flask, start stirring and raise the temperature to 60°C. After the raw materials are completely dissolved, add the potassium perchlorate solution dropwise with the addition funnel. Stirring was continued for 30 min after the addition was complete, the heating was stopped, and the solution was allowed to cool down to room temperature naturally. Put ice cubes into the water bath to reduce the temperature of the solution to below 10°C. After the precipitation is precipitated, quickly filter it with a Buchner funnel, and rinse the filter cake with pure ice water until the filtrate is free of bromide ions. The filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com