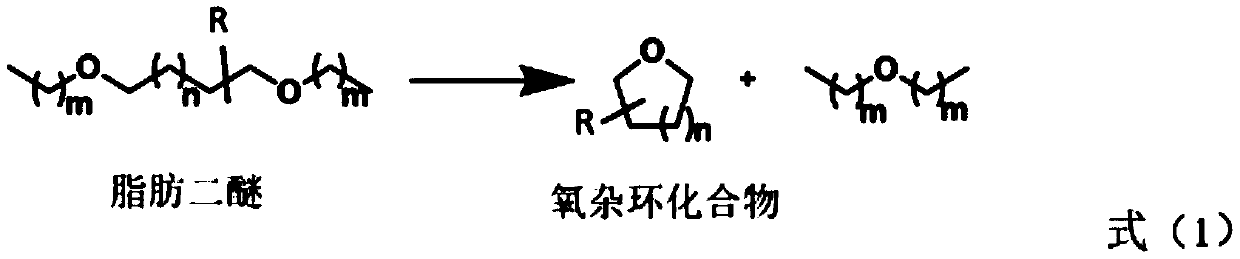

Novel method for preparing oxygen heterocyclic compound through ionic liquid catalysis

A technology of ionic liquids and compounds, applied in the field of catalysis, can solve problems such as unreported, and achieve the effects of no by-products, no metal participation, and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

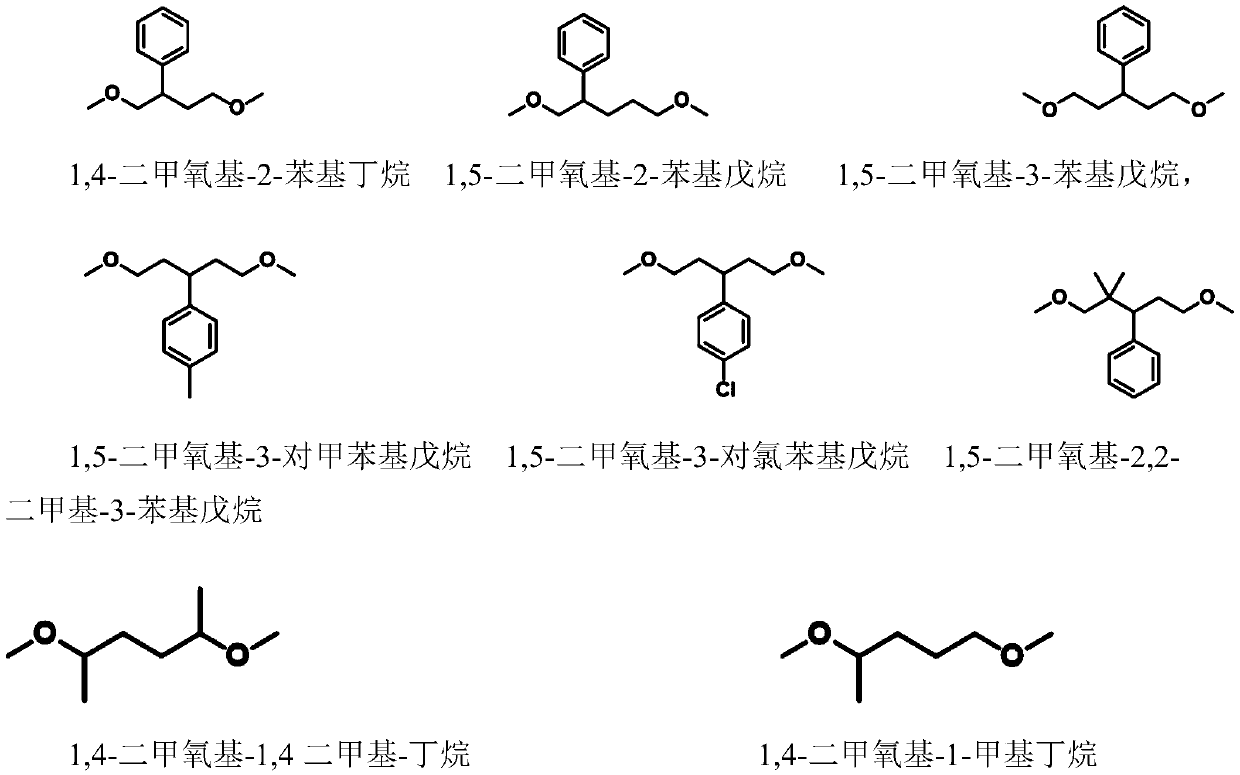

Method used

Image

Examples

Embodiment 1

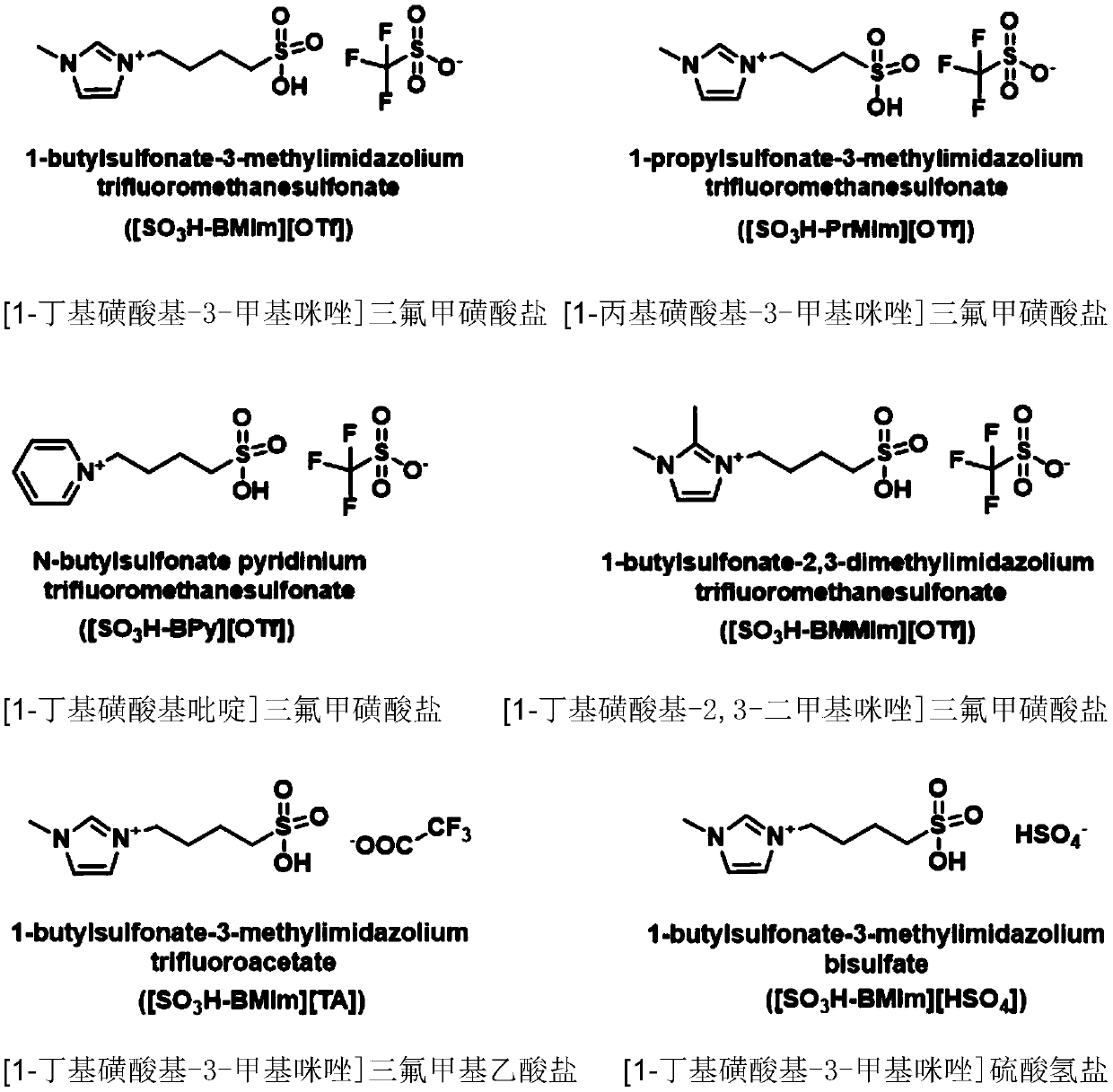

[0039] Example 1, [1-butylsulfonic acid group-3-methylimidazole] trifluoromethanesulfonate catalyzed 1,5-dimethoxypentane to prepare tetrahydropyran

[0040] Mix 2 mmol 1,5-dimethoxypentane with 0.2 mmol ionic liquid [1-butylsulfono-3-methylimidazole] trifluoromethanesulfonate ([SO 3 H-BMIm][OTf]) was placed in a 20 ml stainless steel reaction kettle, sealed; moved to an oil bath at 120°C, stirred and heated for 15 hours; the reaction kettle was immersed in ice water to terminate the reaction, and then left at room temperature for a period of time. The reaction solution was transferred to a separatory funnel and divided into upper and lower layers. Take the upper organic phase, use 1 H and 13 C NMR analysis of its composition and determination of material structure. According to the analysis results, it is determined that the conversion rate of raw materials is 94%, and the product is tetrahydropyran, and its separation yield is 94%.

[0041] reaction product 1 H and 13 ...

Embodiment 2

[0045] Example 2, [1-butylsulfonic acid group-3-methylimidazole] trifluoromethanesulfonate catalyzed 1,5-dimethoxypentane to prepare tetrahydropyran

[0046] Mix 0.1mol 1,5-dimethoxypentane with 0.1mol ionic liquid [SO 3 H-BMIm][OTf] was placed in a 50 ml stainless steel reactor and sealed; moved to an oil bath at 120°C, stirred and heated for 10 hours; the reactor was immersed in ice water to terminate the reaction, and then left at room temperature for a period of time. The reaction solution was transferred to a separatory funnel and divided into upper and lower layers. Take the upper organic phase, use 1 H and 13 C NMR analysis of its composition and determination of material structure. According to the analysis results, it is determined that the conversion rate of raw materials is >99.9%, the product is tetrahydropyran, and the separation yield is >99%.

Embodiment 3

[0047] Example 3, [1-propylsulfonate-3-methylimidazole] triflate catalyzes the preparation of tetrahydropyran from 1,5-dimethoxypentane

[0048] Mix 2 mmol 1,5-dimethoxypentane with 0.2 mmol ionic liquid [1-propylsulfono-3-methylimidazole] trifluoromethanesulfonate ([SO 3 H-PrMIm][OTf]) was placed in a 20 ml stainless steel reaction kettle, sealed; moved to an oil bath at 120°C, stirred and heated for 10 hours; the reaction kettle was immersed in ice water to terminate the reaction, and then left at room temperature for a period of time. The reaction solution was transferred to a separatory funnel and divided into upper and lower layers. Take the upper organic phase, use 1 H and 13 C NMR analysis of its composition and determination of material structure. According to the analysis results, it is determined that the conversion rate of raw materials is 90%, and the product is tetrahydropyran, and its separation yield is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com