A high-strength carbonized flame-retardant yarn

A high-strength, high-strength yarn technology, applied in the field of spinning, can solve problems such as itching, low strength, and single dyeing, and achieve the effect of improving yarn strength, high strength, and improving wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Domestic flame retardant viscose: It is safe and nontoxic, produces no toxic gas when burning, produces less smoke, has high flame retardancy, and has a lasting flame retardant effect. It can keep its original form after carbonization or at a high temperature of 1,100℃ and play a role in blocking. No melting, no dripping, reducing secondary injuries such as scalding, and being degradable after the end of the service life cycle; Bright dyeing and high color fastness.

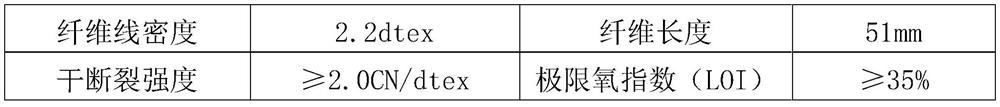

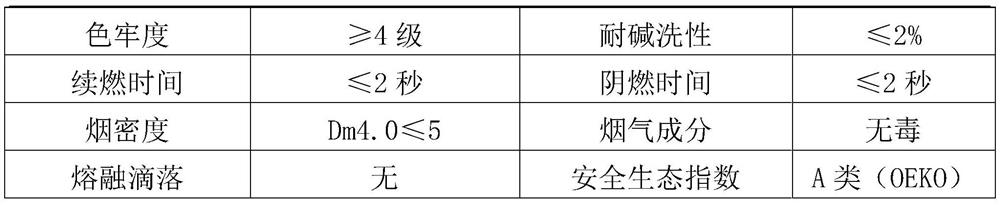

[0011] The main performance indexes of flame retardant viscose fiber are as follows:

[0012] Fiber linear density 2.2dtex fibre length 51mm Dry breaking strength ≥2.0CN / dtex Limiting oxygen index (LOI) ≥35% colour fastness ≥4 grade Alkali washing resistance ≤2% after flame time ≤2 seconds Smoldering time ≤2 seconds Smoke density Dm4.0≤5 Flue gas composition non-poisonous Melting dripping without Ecological index Class a (OEKO)

[0013] Para-aramid 1414:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com