Exhaust gas post-treatment method and exhaust gas post-treatment system for internal combustion engine

A technology for after-treatment of exhaust gas and internal combustion engine, which is applied in the direction of electronic control of exhaust gas treatment device, diagnostic device of exhaust gas treatment device, exhaust gas treatment, etc., can solve the problems of increased water injection cost, high water consumption, damage, etc. To achieve the effect of reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

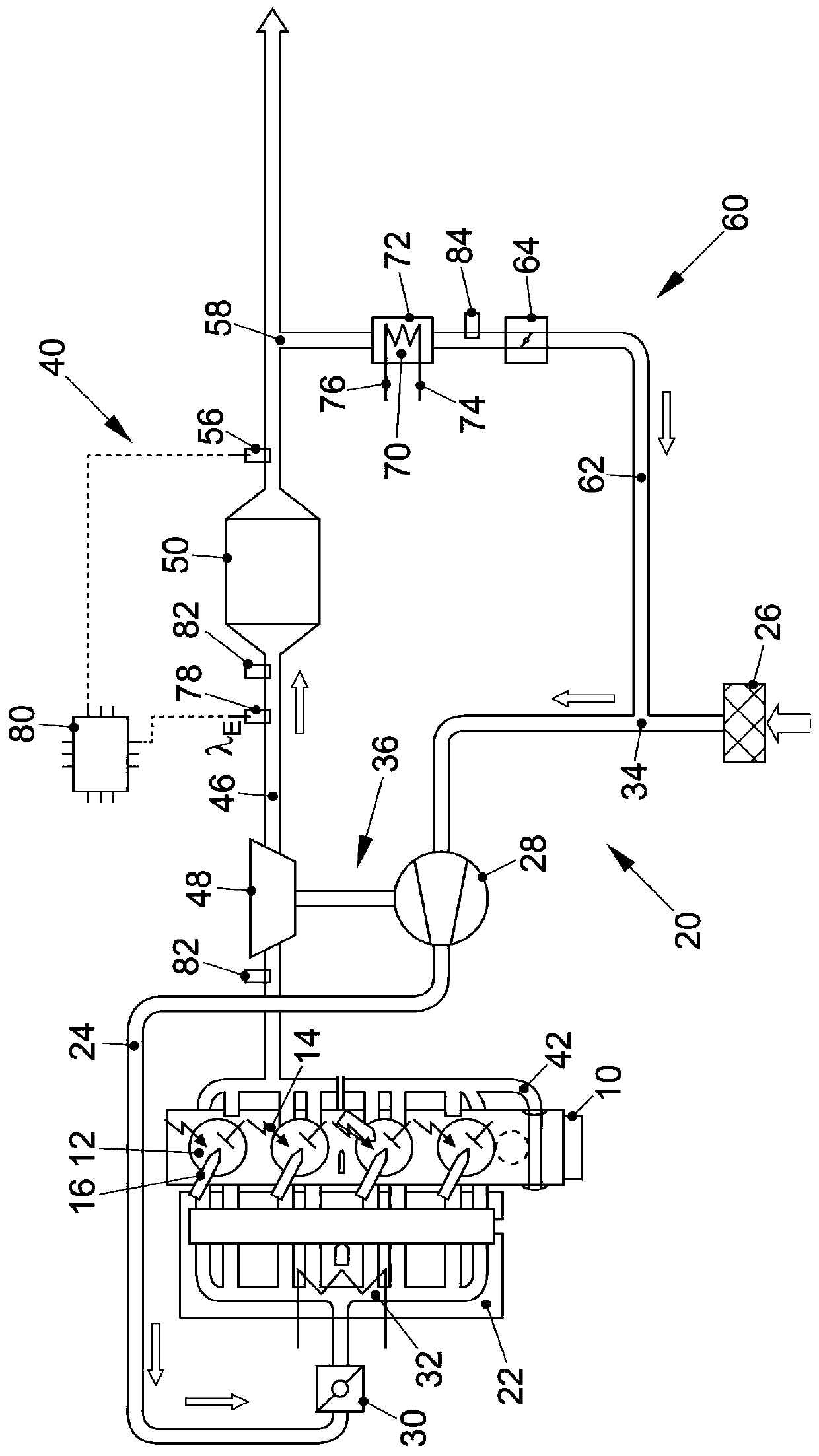

[0037] figure 1 A schematic diagram of an internal combustion engine 10 with an intake system 20 and an exhaust system 40 is shown. Internal combustion engine 10 is designed as a direct-injection gasoline engine and has a plurality of combustion chambers 12 . A fuel injector 16 for injecting fuel into the respective combustion chamber 12 and a spark plug 14 for igniting the fuel-air mixture are respectively arranged at the combustion chambers 12 . The combustion chamber 12 is delimited by a piston 18 which is arranged linearly displaceable in a cylinder bore of the internal combustion engine 10 . The piston 18 is connected to the crankshaft of the internal combustion engine 10 through a connecting rod, and the crankshaft transmits the power of the internal combustion engine 10 to an output shaft that can be connected to the transmission. Internal combustion engine 10 is connected via its intake port 22 to an air supply system 20 and via its exhaust port 42 to an exhaust syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com