A kind of descaling system in copper tube of condenser

A technology for condensers and copper tubes, which is applied in the field of descaling systems in copper tubes of condensers, to achieve the effects of facilitating condensation adhesion, increasing contact area, and prolonging working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

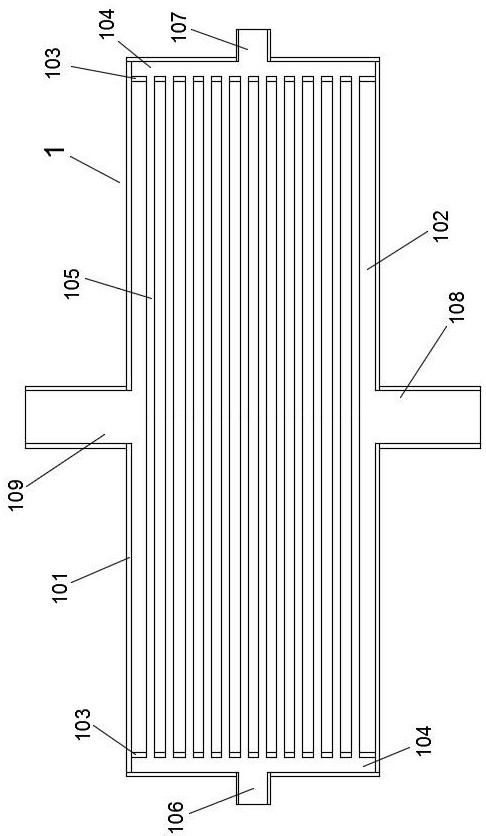

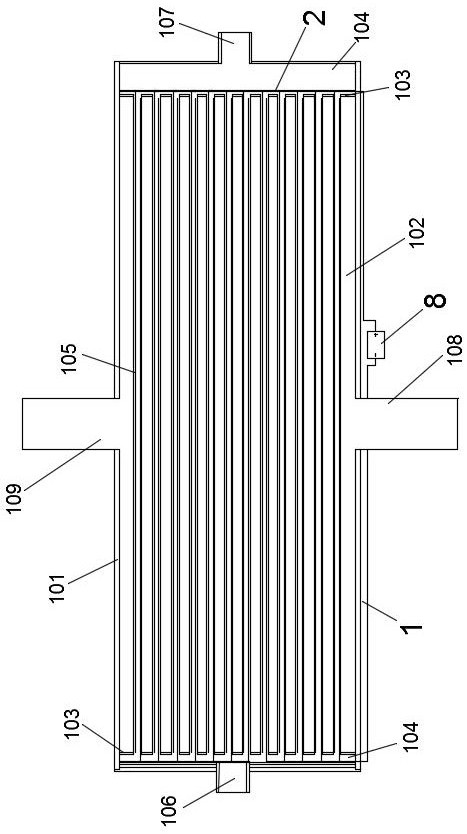

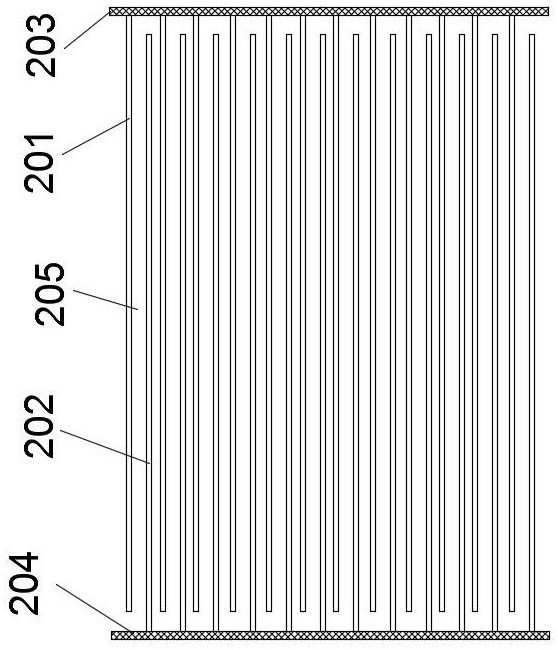

[0054] Such as Figure 2-6 As shown, a descaling system in the copper tube of the condenser, the descaling system 2 is set in the two condensed water converging chambers 104 of the condenser 1, and includes positive metal filters connected to the positive and negative poles of the DC power supply 8 respectively Net 203 and negative electrode metal filter screen 204, wherein, the positive electrode metal filter screen 203 is arranged in the condensed water converging cavity 104 that communicates with the condensed water inlet 107, and there are several arc-shaped positive plates 201 distributed thereon, and these positive plates 201 corresponds to the position and quantity of the condensing copper tubes 105 in the condenser 1 one by one, and extends into the corresponding condensing copper tubes 105 and extends to the other end of the condensing copper tubes 105; the negative metal filter screen 204 It is arranged in the condensed water converging cavity 104 communicated with t...

Embodiment 2

[0059] This embodiment is an improvement made on the basis of Embodiment 1, and its basic structure is the same as that of Embodiment 1, and the improvements are as follows: Figure 7 As shown, the arc-shaped inner walls of the positive electrode plate 201 and the negative electrode plate 202 are oppositely arranged, and arc-shaped recesses 208 and arc-shaped convex ribs 207 extending along the length direction are alternately distributed on the arc-shaped inner walls of the two.

Embodiment 3

[0061] This embodiment is an improvement made on the basis of Embodiment 1, and its basic structure is the same as that of Embodiment 1. The improvement is that the positive plate 201 and the negative plate 202 are metal tungsten plates with a thickness of 1-1.5 mm. , and the surface of the metal tungsten plate is covered with magnesium oxide coating, the coating thickness is 0.2-0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com