A kind of evaporation system and production process of dimethylformamide

A technology of dimethylformamide and evaporation system is applied in the field of production technology to achieve the effects of improving operation cycle, good market promotion significance and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

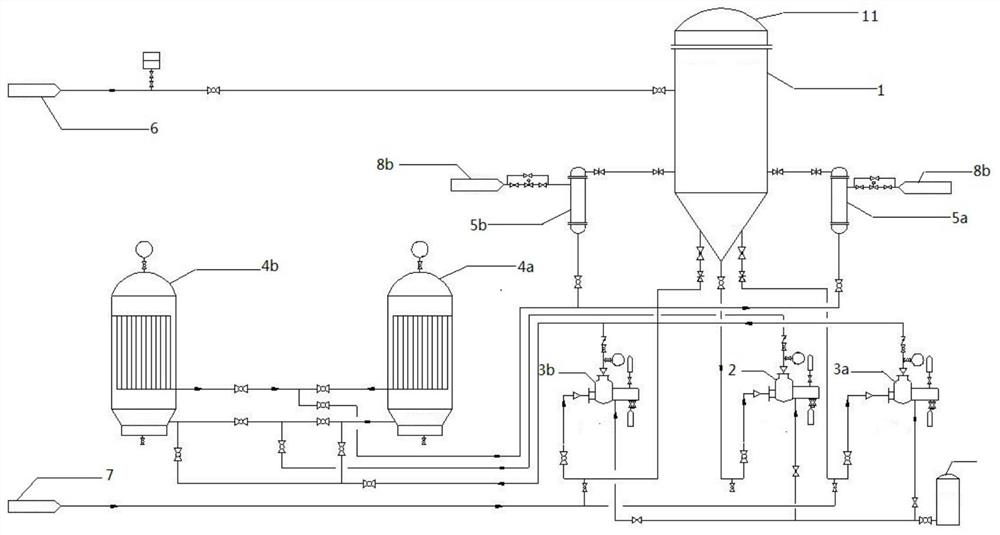

[0046] In this embodiment, an evaporation system of dimethylformamide is provided, and the structure is attached. figure 1 As shown, the evaporation system includes a separator 1, a first circulating pump 2, a second recirculating pump 3, a filter 4, and a heater 6. The DMF material is returned to the separator 1 after the separator 1, the first circulation pump 2, the filter 4, and the heater 6.

[0047] The separator 1 is provided with a liquid level high and low alarm, and the liquid level is controlled at 1.2-2.5m, and the internal temperature is about 173 ° C, and the pressure is controlled at 0.08 MPa. The separator 1 receives the DMF coarse material from the DMF synthesis tower 6, and the DMF coarse is first evaporated for the first time, and the DMF in the gas phase is entered into the initial. Distillation column, the DMF pure to the next step.

[0048] The DMF in the form of the liquid phase flows out from the separator to the first circulation pump 2, and passes through...

Embodiment 2

[0057] In this embodiment, the production process of the evaporation system of the dimethylformamide described in Example 1, the production process includes the following steps:

[0058] (1) Check the valve opening degree and filter 4 sealing, and ensure the sealing of the evaporation system;

[0059] (2) Open the Valve of the DMF synthesis tower 6, the heater 5, when the material in the separator 1 rises to 2.3m, temporarily close the DMF synthesis tower 6 discharge valve, open the second cycle pump 3 import valve, open the cycle Pump outlet into the valve and filter A of the filter A outlet to the valve of the evaporation heater, then open the gas phase valve of the evaporation heater to ensure that the evaporation of the circulating circulation passage valve is smooth, then the evaporation circulation pump is turned on according to the operation procedure of the shielding pump. Or b, establish a system cycle;

[0060] (3) Take the evaporation circulation pump C to ensure smooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com