Beneficiation method of copper-containing talc-serpentinite ore easy to argillate and float

A beneficiation method and serpentine technology, which are applied in the beneficiation of copper sulfide minerals, easy argillization, and easy-to-float copper-bearing talc-serpentine ores in the field of beneficiation, and can solve the problem of poor water solubility, easy-to-float talc-serpentine effects Problems such as flotation effect and difficulty in preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

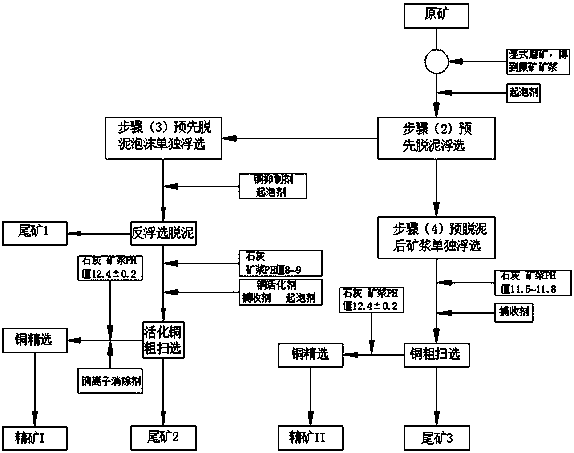

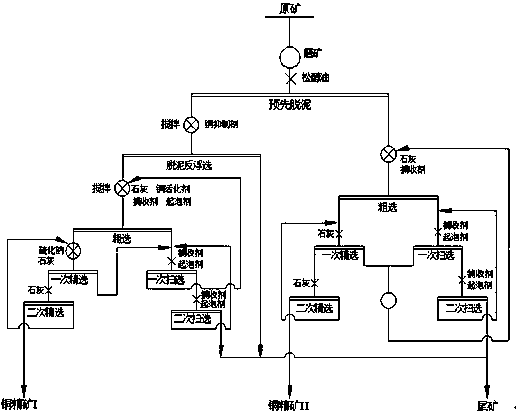

[0027] Embodiment 1: as figure 1 with figure 2 Shown, a kind of beneficiation method of easily muddy, easily float copper-containing talc-serpentinite ore, carry out according to the following steps:

[0028] (1) Grinding: Grinding the ore that is easy to muddy and float with copper-containing talc-serpentinite, the grinding fineness is -0.074mm and the particle size content is 75%, so as to obtain the raw ore slurry;

[0029] (2) Pre-deliming flotation: add foaming agent butyl ether alcohol to the raw ore pulp, the dosage is 2g / t, and carry out pre-flotation of muddy and easy-to-float gangue, so as to obtain pre-deliming foam and pre-deliming pulp ;

[0030] (3) Separate flotation with pre-delimed foam: Add copper mineral inhibitors to the pre-delimed foam obtained in step (2), stir for 5 minutes, and perform desliming and reverse flotation to obtain reverse flotation mud foam and copper gangue-containing pulp after desliming, and reverse flotation desliming Foam is the...

Embodiment 2

[0037] Embodiment 2: as figure 1 with figure 2 Shown, a kind of beneficiation method of easily muddy, easily float copper-containing talc-serpentinite ore, carry out according to the following steps:

[0038] (1) Grinding: Grinding the ore that is easy to muddy and float with copper-containing talc-serpentinite, the grinding fineness is -0.074mm and the particle size content is 75%, so as to obtain the raw ore slurry;

[0039](2) Pre-deliming flotation: add foaming agent butyl ether alcohol to the raw ore pulp, the dosage is 2g / t, and carry out pre-flotation of muddy and easy-to-float gangue, so as to obtain pre-deliming foam and pre-deliming pulp ;

[0040] (3) Separate flotation with pre-delimed foam: Add copper mineral inhibitors to the pre-delimed foam obtained in step (2), stir for 5 minutes, and perform desliming and reverse flotation to obtain reverse flotation mud foam and copper gangue-containing pulp after desliming, and reverse flotation desliming Foam is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com