Preparation method of glass fiber-reinforced PA56/PP alloy material

An alloy material and glass fiber technology, which is applied in the field of preparation of glass fiber reinforced PA56/PP alloy materials, can solve the problems of unstable crystallisation, poor dimensional stability and low impact strength of PA56, and achieve good mechanical properties and dimensional stability, The effect of good anti-oxidation performance and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

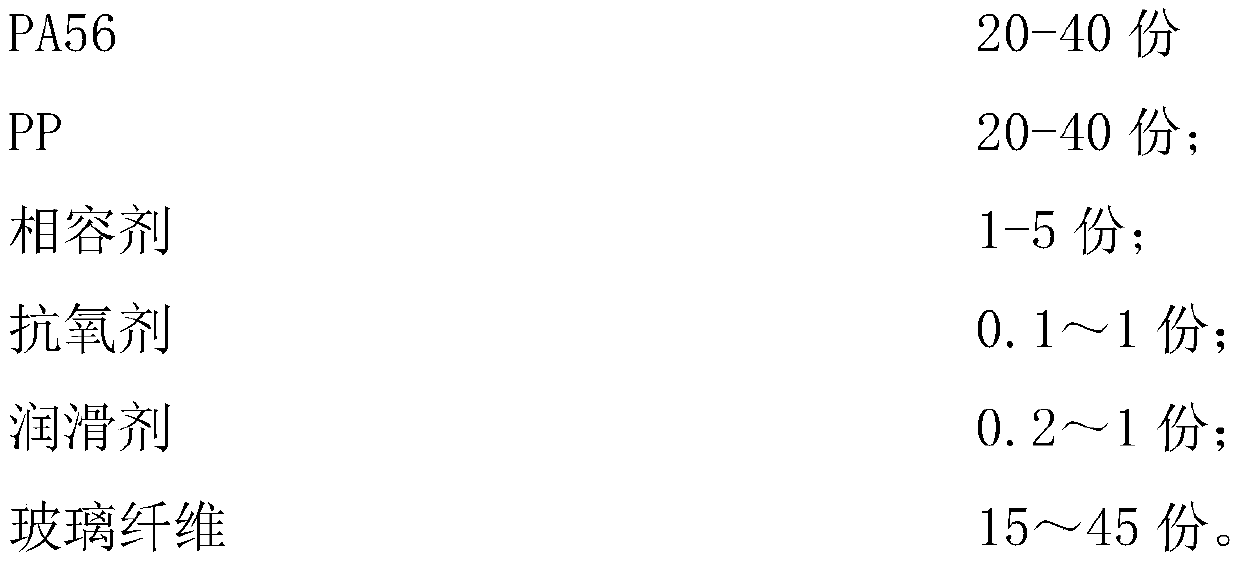

Method used

Image

Examples

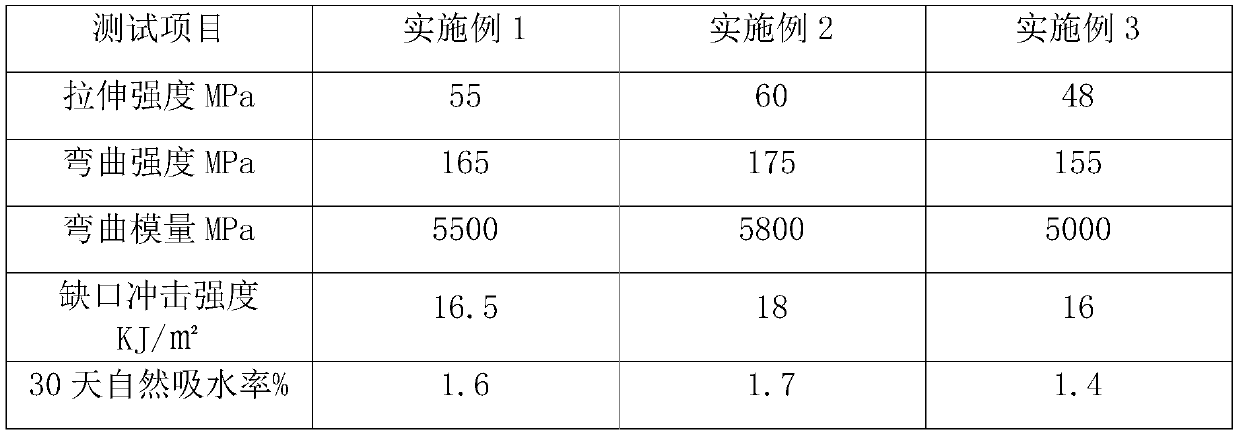

Embodiment 1

[0024] The glass fiber reinforced PA56 / PP alloy material used in this embodiment consists of the following components by weight: 44.5 parts of PA56, 20 parts of PP, 5 parts of compatibilizer, 0.2 part of antioxidant, 0.3 part of lubricant, 30 parts of Composed of glass fibers.

[0025] The preparation method for the glass fiber reinforced PA56 / PP alloy material of the present embodiment comprises the following steps:

[0026] S1. Blend PA56, PP, compatibilizer, antioxidant and lubricant in proportion and stir evenly;

[0027] S2. Add the mixture obtained in step S1 into the twin-screw extruder. The temperature of the twin-screw extruder has 9 zones in total, and the process temperatures of the eight zones are 265°C, 260°C, 255°C, 245°C, and 235°C. , 230°C, 225°C, 225°C, 230°C, the speed of the main machine is controlled at 400 rpm, and chopped glass fibers are added from the side feed during the extrusion process, and finally extruded, cooled, drawn, and pelletized. Finally,...

Embodiment 2

[0030] The glass fiber reinforced PA56 / PP alloy material used in this embodiment consists of the following components by weight: 44.5 parts of PA56, 10 parts of PP, 5 parts of compatibilizer, 0.2 part of antioxidant, 0.3 part of lubricant, 40 parts Composed of glass fibers.

[0031] The preparation method for the glass fiber reinforced PA56 / PP alloy material of the present embodiment comprises the following steps:

[0032] S1. Blend PA56, PP, compatibilizer, antioxidant and lubricant in proportion and stir evenly;

[0033] S2. Add the mixture obtained in step S1 into the twin-screw extruder. The temperature of the twin-screw extruder has 9 zones in total, and the process temperatures of the eight zones are 265°C, 260°C, 255°C, 245°C, and 235°C. , 230°C, 225°C, 225°C, 230°C, the speed of the main machine is controlled at 400 rpm, and chopped glass fibers are added from the side feed during the extrusion process, and finally extruded, cooled, drawn, and pelletized. Finally, th...

Embodiment 3

[0036] The glass fiber reinforced PA56 / PP alloy material used in this embodiment consists of the following components by weight: 44.5 parts of PA56, 30 parts of PP, 5 parts of compatibilizer, 0.2 part of antioxidant, 0.3 part of lubricant, 20 parts Composed of glass fibers.

[0037] The preparation method for the glass fiber reinforced PA56 / PP alloy material of the present embodiment comprises the following steps:

[0038] S1. Blend PA56, PP, compatibilizer, antioxidant and lubricant in proportion and stir evenly;

[0039] S2. Add the mixture obtained in step S1 into the twin-screw extruder. The temperature of the twin-screw extruder has 9 zones in total, and the process temperatures of the eight zones are 265°C, 260°C, 255°C, 245°C, and 235°C. , 230°C, 225°C, 225°C, 230°C, the speed of the main machine is controlled at 400 rpm, and chopped glass fibers are added from the side feed during the extrusion process, and finally extruded, cooled, drawn, and pelletized. Finally, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com