Deacidifying agent for base oil of crude lubricating oil and preparation method thereof

A technology of lubricating base oil and deacidification agent, which is applied in the direction of lubricating composition, chemical instruments and methods, inorganic chemistry, etc., and can solve the problems of high viscosity of regenerated base oil and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

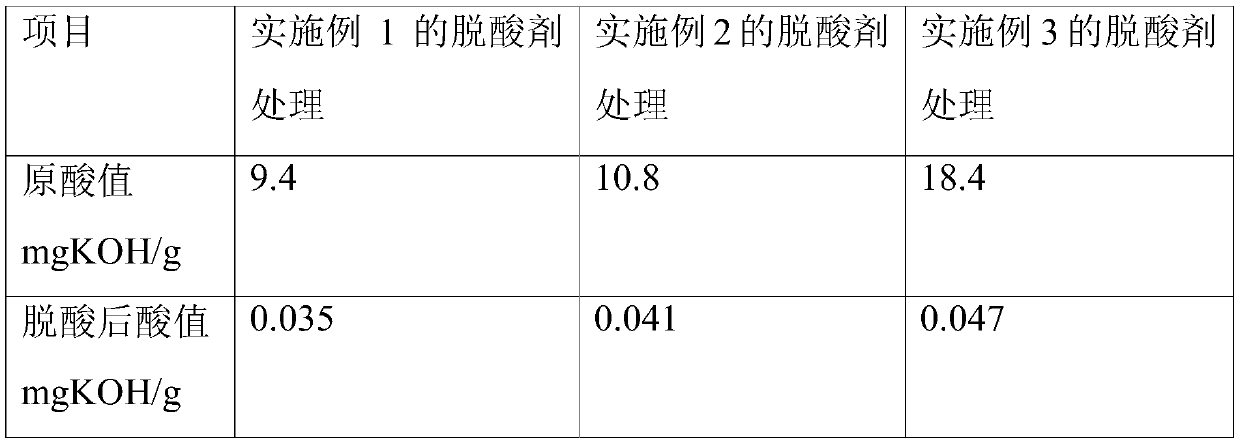

Examples

Embodiment 1

[0038] Deacidification agent for crude lubricating oil base oil, including A component, B component and C component;

[0039] Component A includes 24 parts of aluminum oxide, 21 parts of calcium oxide, 3.4 parts of zinc chloride, and 4.5 parts of magnesium chloride in parts by mass;

[0040] According to parts by mass, component B includes 16 parts of ammonia water, 15 parts of caustic soda, and 55 parts of water; wherein ammonia water contains NH 3 Not less than 20%;

[0041] Component C includes 17 parts of activated carbon, 14 parts of modified montmorillonite, and 6 parts of modified white clay according to the number of parts by mass; 95% of the particle size of activated carbon is 200 to 300 mesh, and the specific surface area is 100 to 200m 2 / g.

[0042] The preparation method of the deacidifying agent of crude lubricating oil base oil, comprises the following steps:

[0043] (1) Group A is prepared according to the ratio of aluminum oxide, calcium oxide, zinc chlor...

Embodiment 2

[0063] Deacidification agent for crude lubricating oil base oil, including A component, B component and C component;

[0064] Component A includes 31 parts of aluminum oxide, 15 parts of calcium oxide, 5 parts of zinc chloride, and 5 parts of magnesium chloride in parts by mass;

[0065] Component B includes 10 parts of ammonia water, 16 parts of caustic soda, and 53 parts of water in parts by mass; wherein ammonia water contains NH 3 Not less than 20%;

[0066] Component C includes 17 parts of activated carbon, 13 parts of modified montmorillonite, and 8 parts of modified clay according to the number of parts by mass; the particle size of activated carbon is 95% in the range of 200 to 300 mesh, and the specific surface area is 100 to 200m 2 / g.

[0067] The preparation method of the deacidifying agent of crude lubricating oil base oil, comprises the following steps:

[0068] (1) Group A is prepared according to the ratio of aluminum oxide, calcium oxide, zinc chloride, and...

Embodiment 3

[0088] Deacidification agent for crude lubricating oil base oil, including A component, B component and C component;

[0089] Component A includes 22 parts of aluminum oxide, 25 parts of calcium oxide, 2 parts of zinc chloride and 3 parts of magnesium chloride in parts by mass;

[0090] According to parts by mass, component B includes 19 parts of ammonia water, 20 parts of caustic soda, and 60 parts of water; wherein ammonia water contains NH 3 Not less than 20%;

[0091] Component C includes 20 parts of activated carbon, 20 parts of modified montmorillonite, and 5 parts of modified white clay according to the number of parts by mass; 95% of the particle size of activated carbon is 200 to 300 mesh, and the specific surface area is 100 to 200m 2 / g.

[0092] The preparation method of the deacidifying agent of crude lubricating oil base oil, comprises the following steps:

[0093] (1) Group A is prepared according to the ratio of aluminum oxide, calcium oxide, zinc chloride, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com