Preparation method of degradable artificial leather based on forestry and agricultural residues

A technology of agricultural and forestry waste and artificial leather, which is applied in the field of preparation of degradable artificial leather based on agricultural and forestry waste, can solve the problems of inability to achieve high biodegradation rate and poor tear resistance, and achieve abundant yield and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

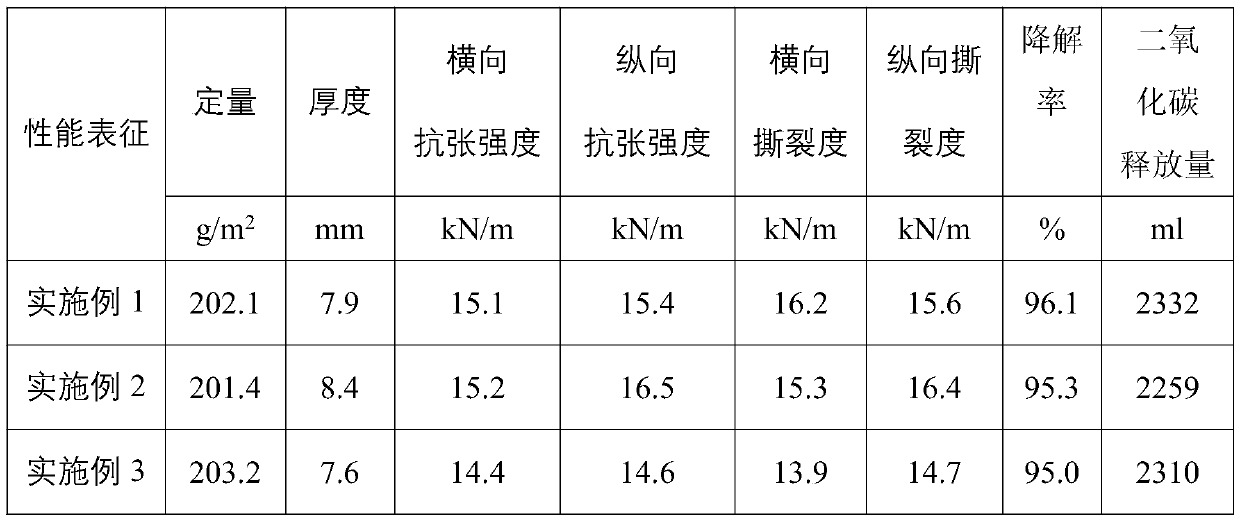

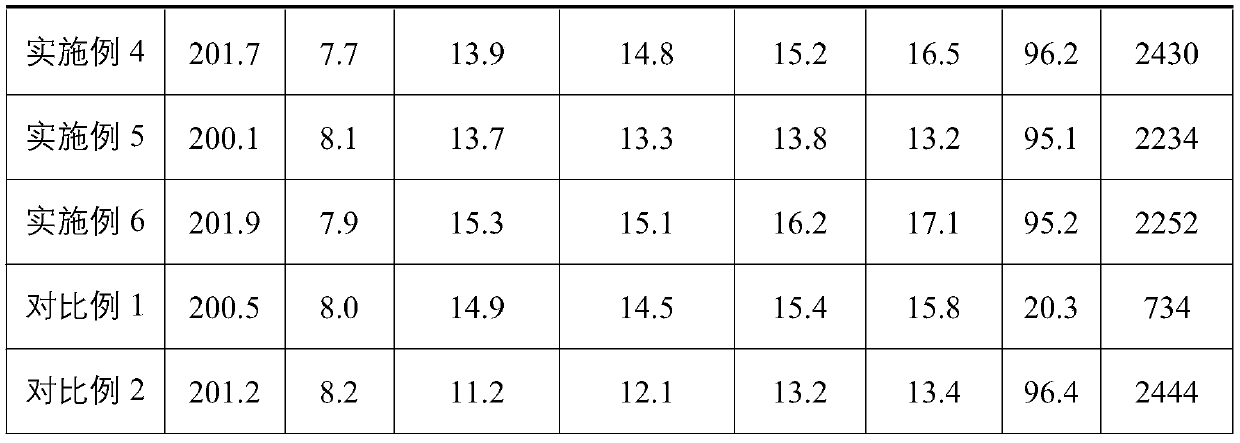

Embodiment 1

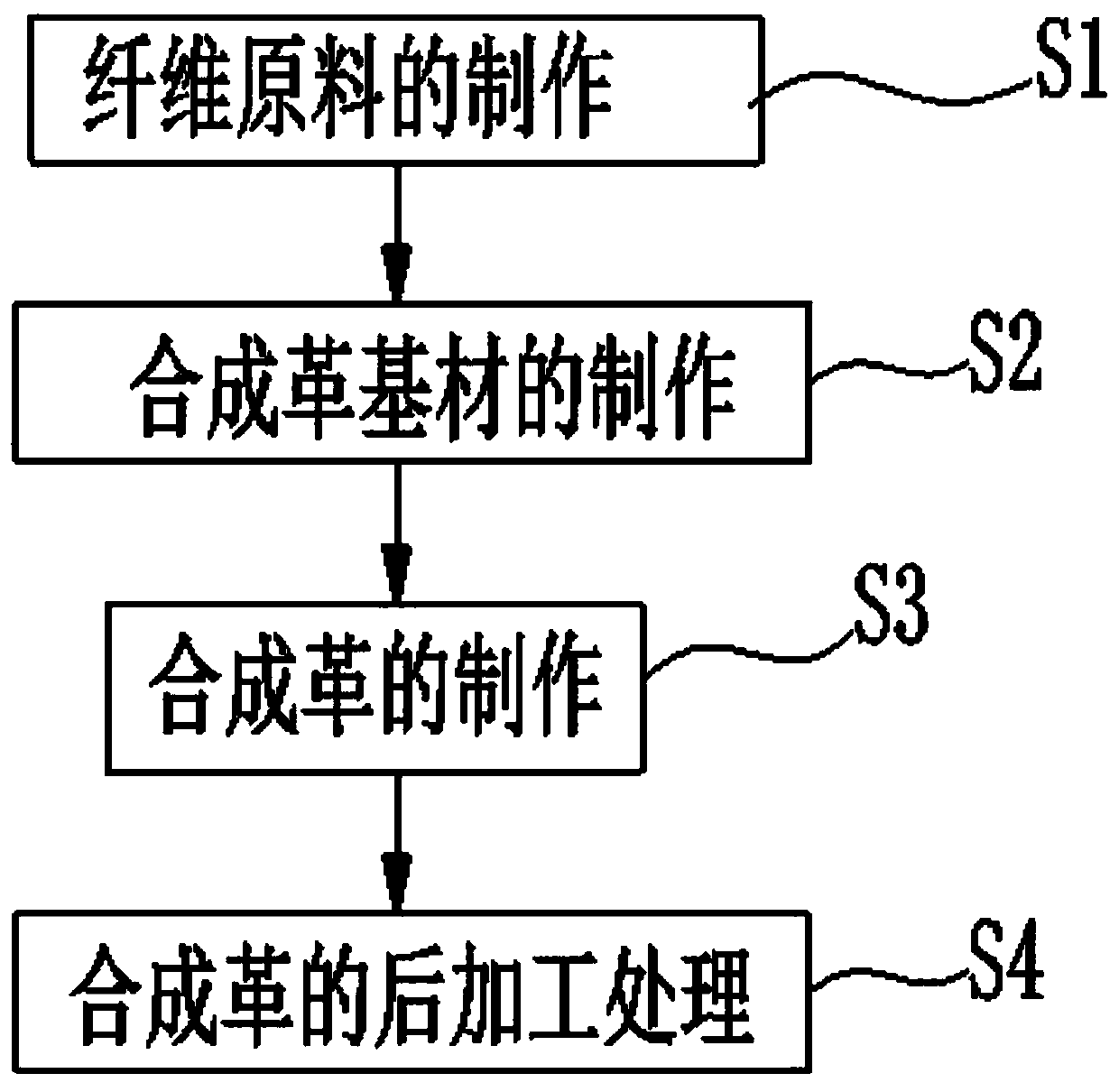

[0037] A method for preparing degradable artificial leather based on agricultural and forestry waste, specifically comprising the following steps:

[0038] S1, the production of fiber raw materials:

[0039] S11. Select agricultural and forestry waste crop straw and wood, in parts by mass: 70 parts of crop straw, 30 parts of wood, mix well and place in a cooking pot, add sodium dithionite solution with a mass concentration of 1% as a cooking aid to cook;

[0040] S12. After the cooked mixed slurry is screened by a screening machine, it is transported to a beating machine for beating treatment, and the beating degree of the slurry is controlled to be 30±2°SR;

[0041] S13, placing the beaten slurry in an oven to dry to obtain a natural color slurry for later use;

[0042] S2. Production of synthetic leather substrate:

[0043] S21. Place the uncolored slurry in a rough opener for rough opening, and then place it in a fine opener for fine opening, so that the uncolored slurry...

Embodiment 2

[0049] A method for preparing degradable artificial leather based on agricultural and forestry wastes, the steps of which are basically the same as in Example 1, except that the bio-based resin impregnation solution in step S2 is obtained by the following method: in parts by mass, acrylic resin 80 parts, 2 parts of thickener polyethylene glycol, 1 part of activator fatty alcohol polyoxyethylene ether, 1 part of softening agent pentaerythritol fatty acid ester, all the other technical characteristics are identical with embodiment 1.

Embodiment 3

[0051]A method for preparing degradable artificial leather based on agricultural and forestry wastes, the steps of which are basically the same as in Example 1, except that the bio-based resin impregnation solution in step S2 is obtained by the following method: in parts by mass, acrylic resin 100 parts, 4 parts of thickener polyethylene glycol, 3 parts of activator fatty alcohol polyoxyethylene ether, 2 parts of softening agent pentaerythritol fatty acid esters, all the other technical characteristics are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com