Low-temperature phase-change heat exchanger applied to cell vitrification

A vitrification freezing and low-temperature phase change technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of single driving force, improve the temperature uniformity, strengthen the flow heat transfer process, and reduce the cell's damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further description below in conjunction with accompanying drawing:

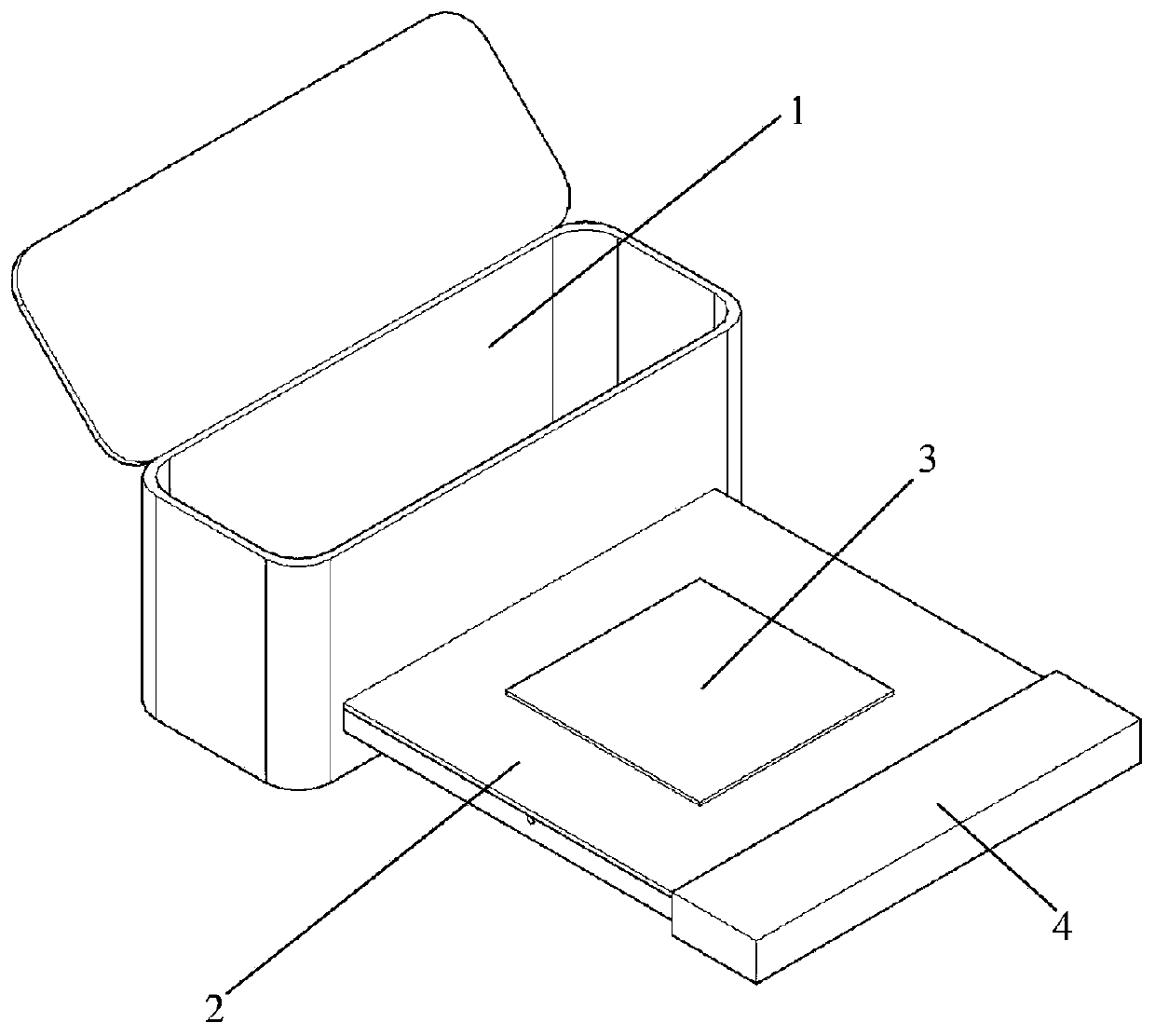

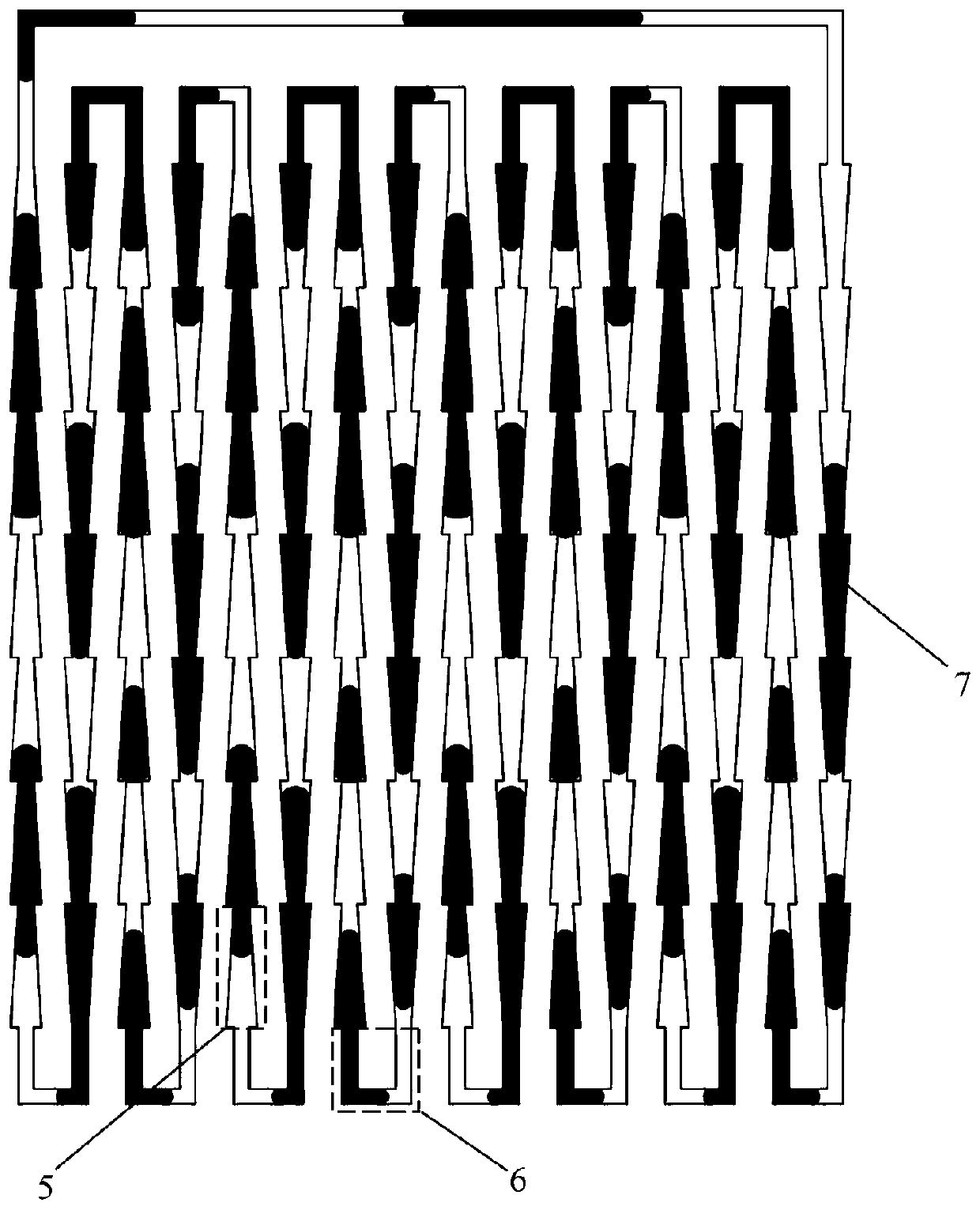

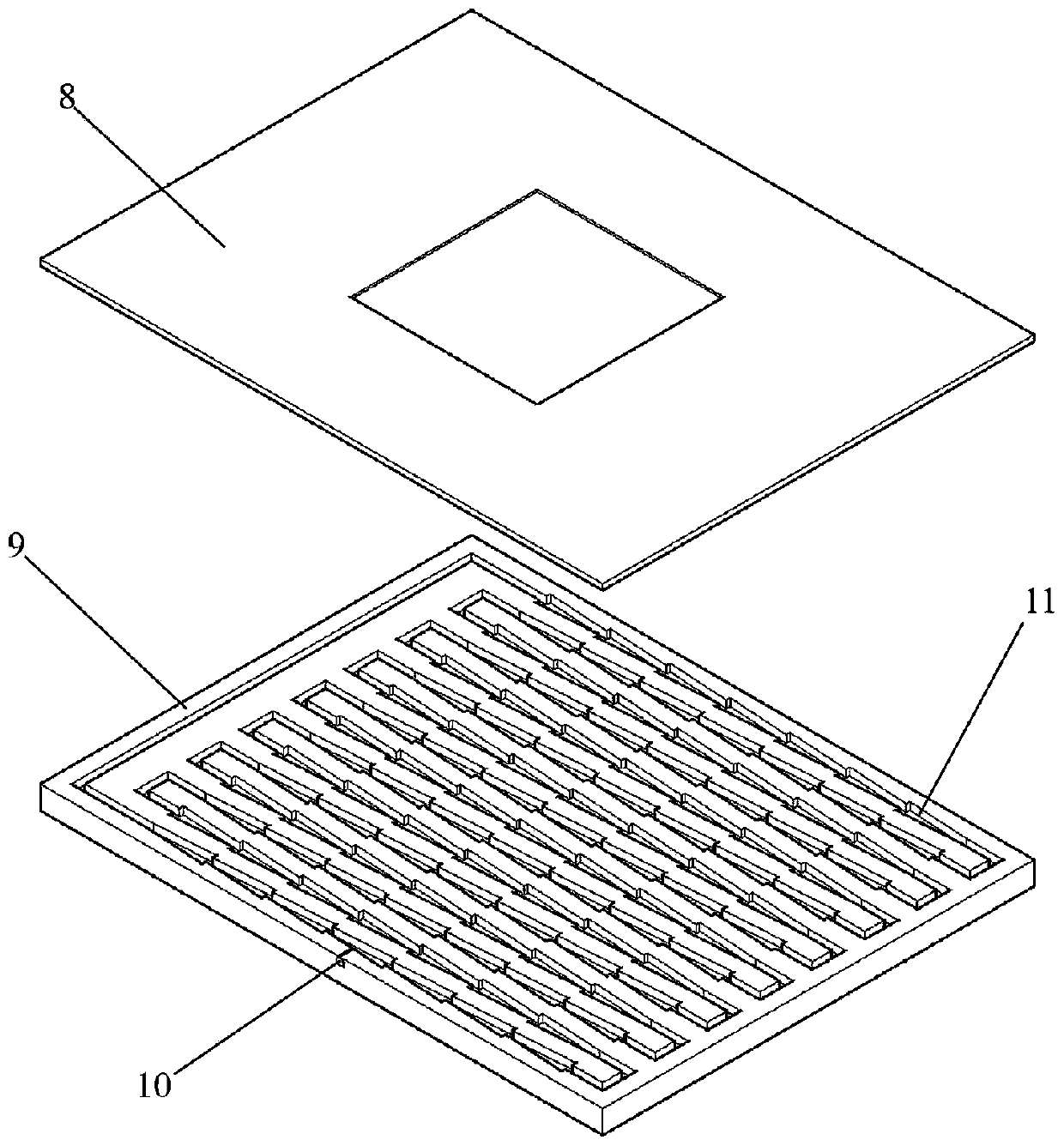

[0024] figure 1It is a system diagram of a low-temperature phase-change heat exchanger applied to cell vitrification in the present invention. As shown in the figure, the system includes a silicon-based continuous contraction-expanding plate-type pulsating heat pipe, a cell suspension storage device, a heating device, and a condensation box. The evaporating section of the silicon-based continuous shrinking-expanding plate-type pulsating heat pipe 2 is fixed in the outer shell of the heating device 4, the condensation section of the silicon-based continuous shrinking-expanding plate-type pulsating heat pipe 2 is fixed in the condensation box 1, and the cell suspension holding device 3 is coupled On the upper surface of the silicon-based continuous contraction-expansion plate type pulsating heat pipe 2 . During operation, the heating device 4 inputs heat load to the evaporation section of the silicon-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com