Preparation method of coating type zinc electrode

A zinc electrode and coating technology, applied in the field of zinc electrode preparation, can solve problems affecting battery capacity, internal resistance cycle life, electrode active material coating surface density, uneven coating thickness, poor consistency, etc., to achieve a large increase The effect of current discharge capability, thickness reduction, and uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

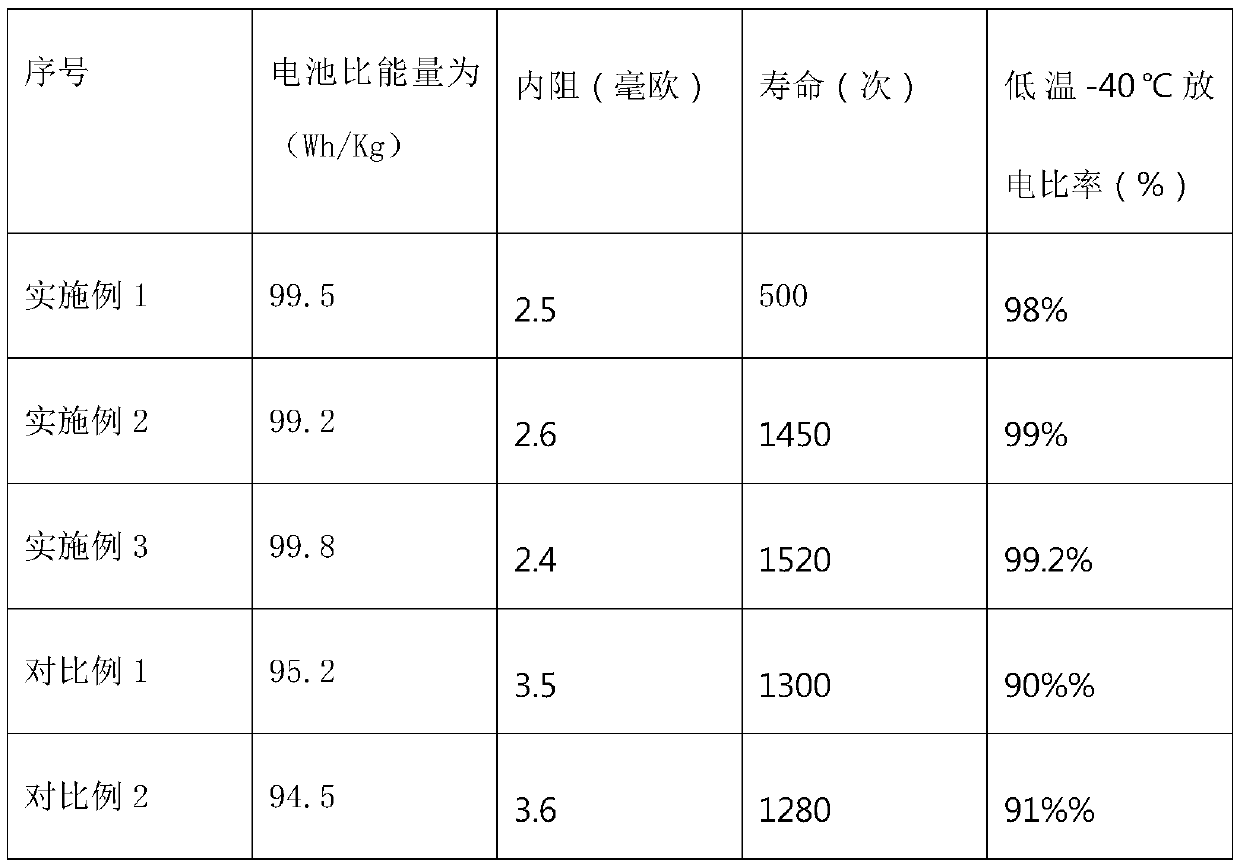

Embodiment 1

[0030] The zinc-nickel battery negative active material of the present embodiment comprises the following components: zinc oxide 60%, zinc powder 15%, bismuth oxide 3%, PTFE 3%, dispersant sodium polyacrylate 0.5%, carboxymethyl cellulose 0.5% and Water 18%.

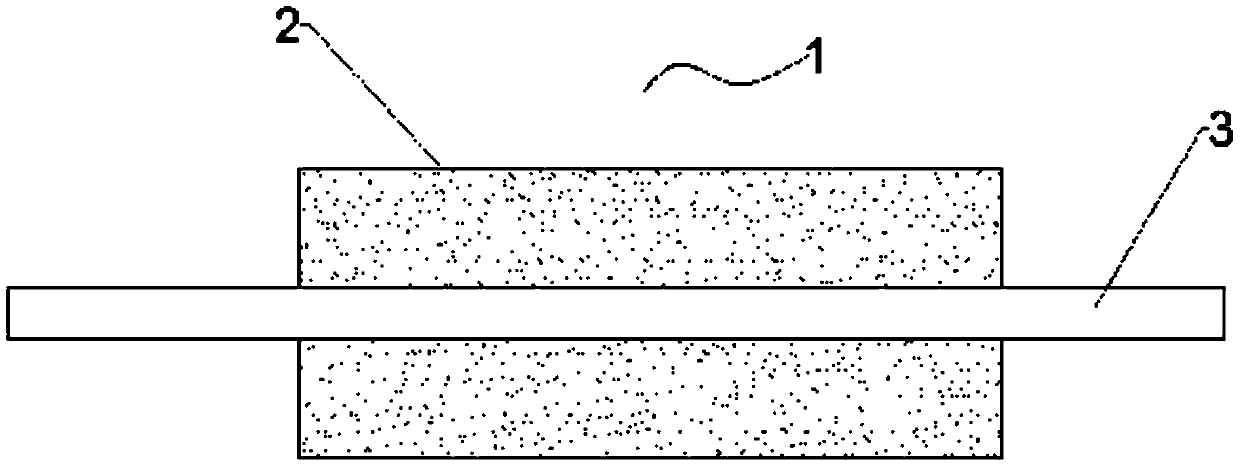

[0031] The zinc-nickel battery negative electrode sheet 1 of this embodiment includes a current collector copper foil 3 and a negative electrode active material 2 coated on the current collector, and the negative electrode active material is the above-mentioned negative electrode active material of the zinc-nickel battery.

[0032] The preparation method of the zinc-nickel battery negative plate of the present embodiment comprises the following steps:

[0033] 1) The above-mentioned zinc-nickel battery negative electrode active material 2 is firstly weighed according to the formula ratio, mixed evenly, and then added into a mixer and stirred evenly to obtain the negative electrode slurry;

[0034] 2) The negative electr...

Embodiment 2

[0038] The zinc-nickel battery negative active material of the present embodiment comprises the following components: zinc oxide 65%, zinc powder 12%, bismuth oxide 2.5%, hydroxyethyl cellulose 2.5%, dispersant glycerin 1%, carboxymethyl cellulose 1% % with water 16%.

[0039] The zinc-nickel battery negative electrode sheet 1 of this embodiment includes a current collector copper foil 3 and a negative electrode active material 2 coated on the current collector, and the negative electrode active material is the above-mentioned negative electrode active material of the zinc-nickel battery.

[0040] The preparation method of the zinc-nickel battery negative plate of the present embodiment comprises the following steps:

[0041] 1) Mix the above-mentioned negative electrode active material 2 of the zinc-nickel battery evenly, and add it into a mixer to stir evenly to obtain the negative electrode slurry;

[0042] 2) The negative electrode slurry prepared in step 1) is coated on ...

Embodiment 3

[0045] The zinc-nickel battery negative active material of the present embodiment comprises the following components: zinc oxide 70%, zinc powder 12%, bismuth oxide 2%, PTFE 2%, dispersant sodium polyacrylate 0.5%, carboxymethyl cellulose 0.5% and Water 13%.

[0046] The zinc-nickel battery negative electrode sheet 1 of this embodiment includes a current collector copper foil 3 and a negative electrode active material 2 coated on the current collector, and the negative electrode active material is the above-mentioned negative electrode active material of the zinc-nickel battery.

[0047] The preparation method of the zinc-nickel battery negative plate of the present embodiment comprises the following steps:

[0048] 1) Mix the above-mentioned zinc-nickel battery negative electrode active material 2 evenly, and add it into a mixer to stir evenly to obtain the negative electrode slurry;

[0049] 2) Coat the negative electrode slurry prepared in step 1) on the current collector ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com