A microcapsule with pH response and intestinal targeting and preparation method thereof

A microcapsule, targeting technology, applied in microcapsules, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of poor targeted release effect, low embedding rate, poor stability, etc. , to achieve the effect of simple method, high solubility and high embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

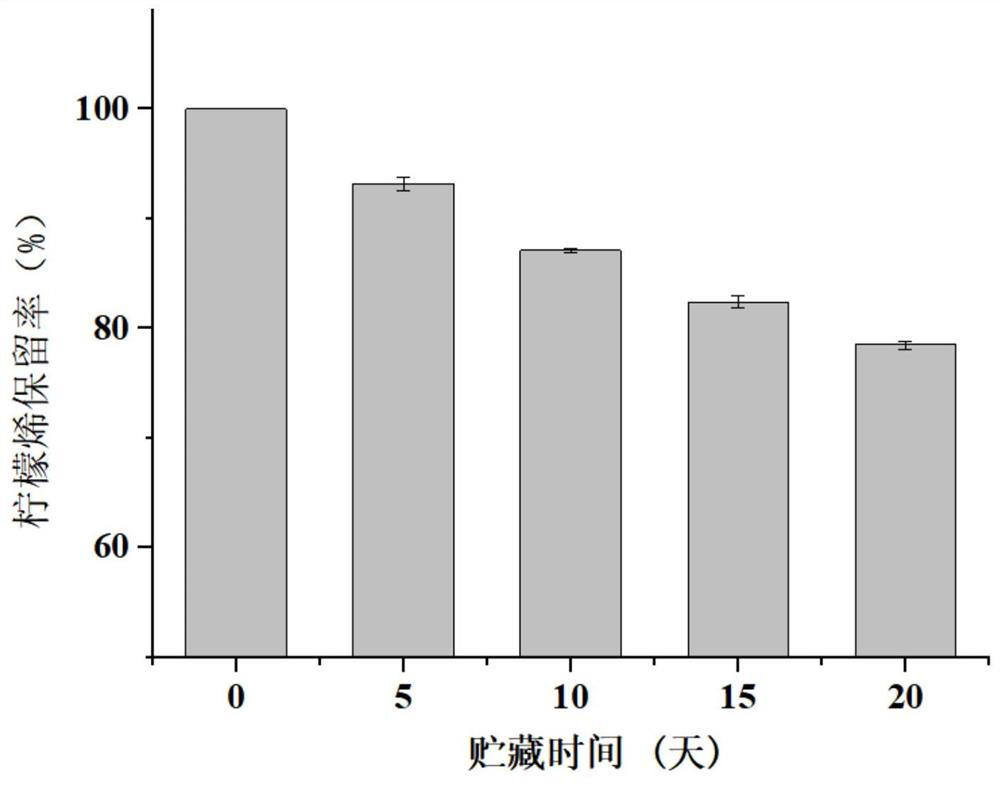

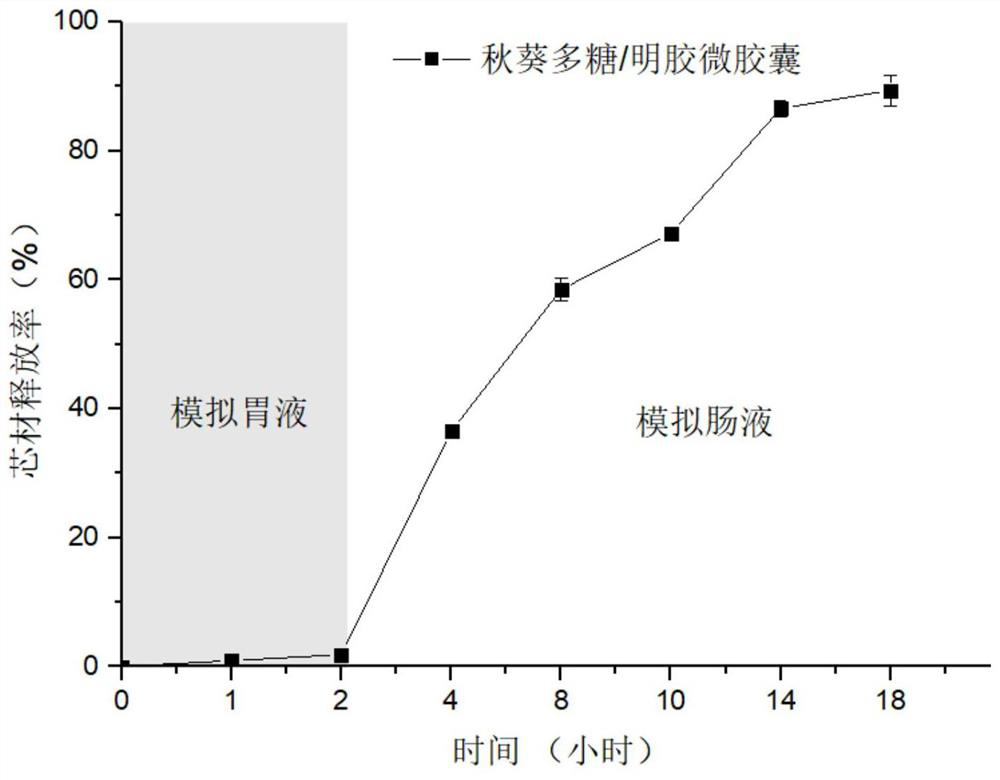

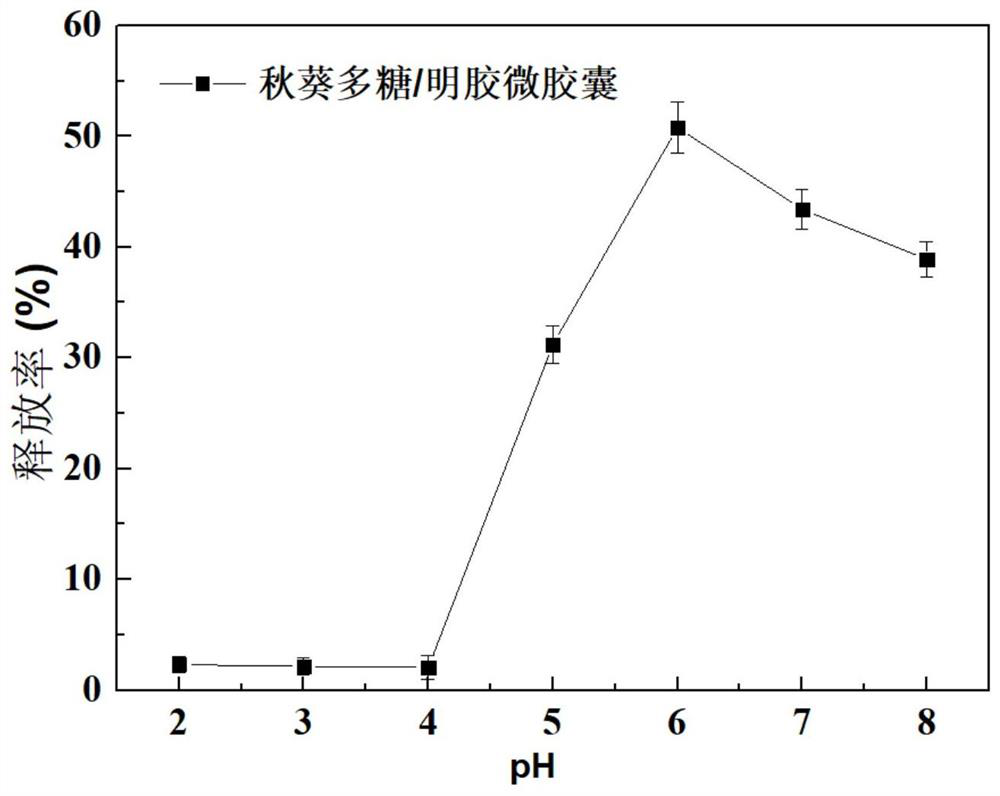

[0030] A preparation method for loading limonene microcapsules, comprising the following steps in turn:

[0031] (1) After the okra is cleaned and deseeded, the okra is sequentially freeze-dried and crushed to 60 meshes, and then the okra is ultrasonically extracted for 60 minutes at a temperature of 80° C., and then filtered, alcohol-precipitated and freeze-dried to obtain okra polysaccharides, and then Add pure water and filter through a filter membrane with a pore size of 0.2 μm to obtain a okra polysaccharide solution with a concentration of 2% by weight; wherein, the solid-liquid ratio in the ultrasonic extraction process is 20:1;

[0032] (2) Dissolving the gelatin with pure water, and then magnetically stirring to completely expand, the temperature during stirring is 50°C, the time is 80min, and the gelatin solution having a concentration of 2wt% is obtained by filtering through a filter membrane with a pore size of 0.2 μm;

[0033] (3) Stir and mix the okra polysacchar...

Embodiment 2

[0038] A preparation method for loading isoquercitrin microcapsules, comprising the following steps in turn:

[0039] (1) After the okra is cleaned and deseeded, the okra is sequentially freeze-dried and crushed to 60 meshes, and then the okra is ultrasonically extracted for 60 minutes at a temperature of 80° C., and then filtered, alcohol-precipitated and freeze-dried to obtain okra polysaccharides, and then Add pure water and filter through a filter membrane with a pore size of 0.2 μm to obtain a okra polysaccharide solution with a concentration of 3% by weight; wherein, the solid-liquid ratio in the ultrasonic extraction process is 20:1;

[0040] (2) Dissolving the gelatin with pure water, and then magnetically stirring to completely expand, the temperature during stirring is 50°C, the time is 100min, and the gelatin solution with a concentration of 3wt% is obtained by filtering through a filter membrane with a pore size of 0.2 μm;

[0041] (3) Stir and mix the okra polysac...

Embodiment 3

[0047] A preparation method for loading cinnamaldehyde microcapsules, comprising the following steps in turn:

[0048] (1) After the okra is cleaned and deseeded, it is freeze-dried and crushed to 60 meshes in turn, and then the okra is ultrasonically extracted for 80 minutes at a temperature of 60° C., and then filtered, alcohol-precipitated and freeze-dried to obtain okra polysaccharides, and then Add pure water and filter through a filter membrane with a pore size of 0.2 μm to obtain a okra polysaccharide solution with a concentration of 2% by weight; wherein, the solid-liquid ratio in the ultrasonic extraction process is 20:1;

[0049] (2) Dissolving the gelatin with pure water, and then magnetically stirring to completely expand, the temperature during stirring is 60°C, the time is 60min, and the gelatin solution with a concentration of 4wt% is obtained by filtering through a filter membrane with a pore size of 0.2 μm;

[0050] (3) Stir and mix the okra polysaccharide sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com