A coal gangue separation method based on depth vision

A coal gangue and ore technology, applied in the field of coal gangue separation based on depth vision, can solve the problems of reduced recognition accuracy, difficulty in automation, and low reliability, and achieve high separation efficiency, high detection accuracy, and strong real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

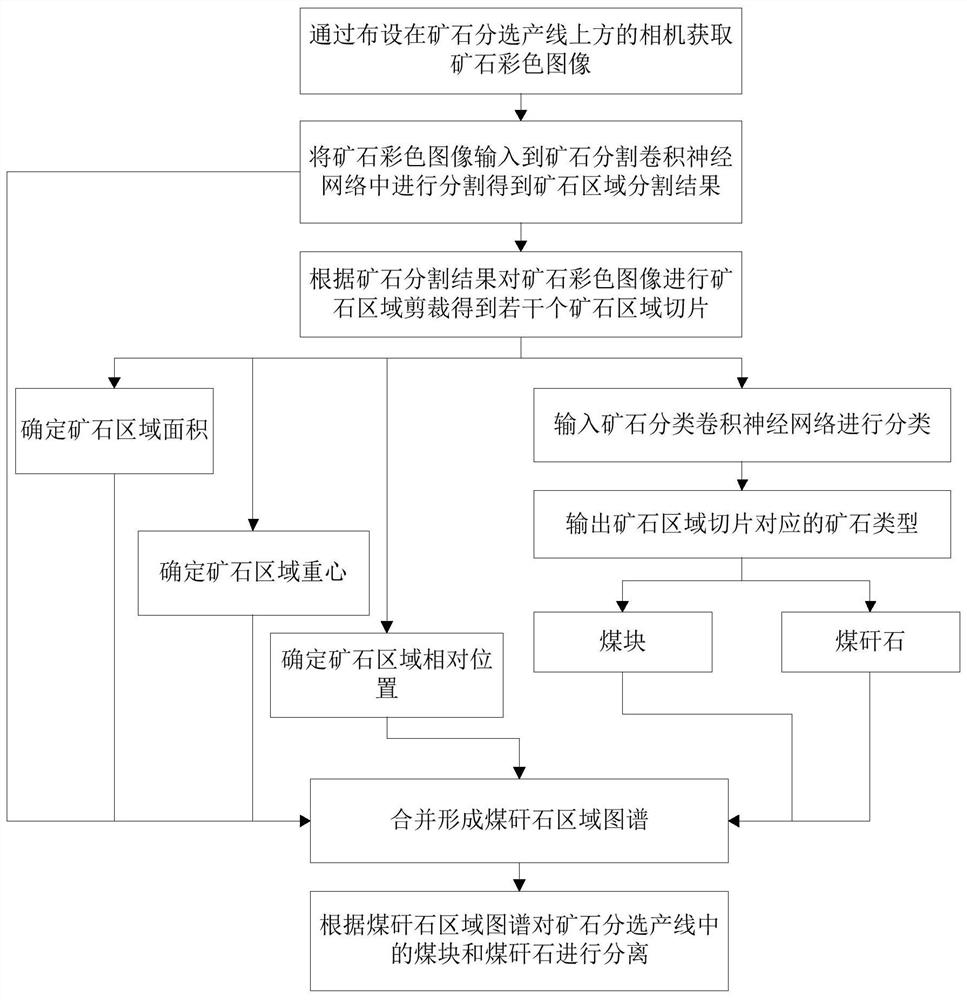

[0038] This application discloses a method for separating coal gangue based on depth vision, please refer to figure 1 As shown in the flowchart, the method includes the following steps:

[0039] 1. Obtain color images of ore through the camera arranged above the ore sorting production line. The ore in the ore sorting production line includes coal lumps and coal gangue.

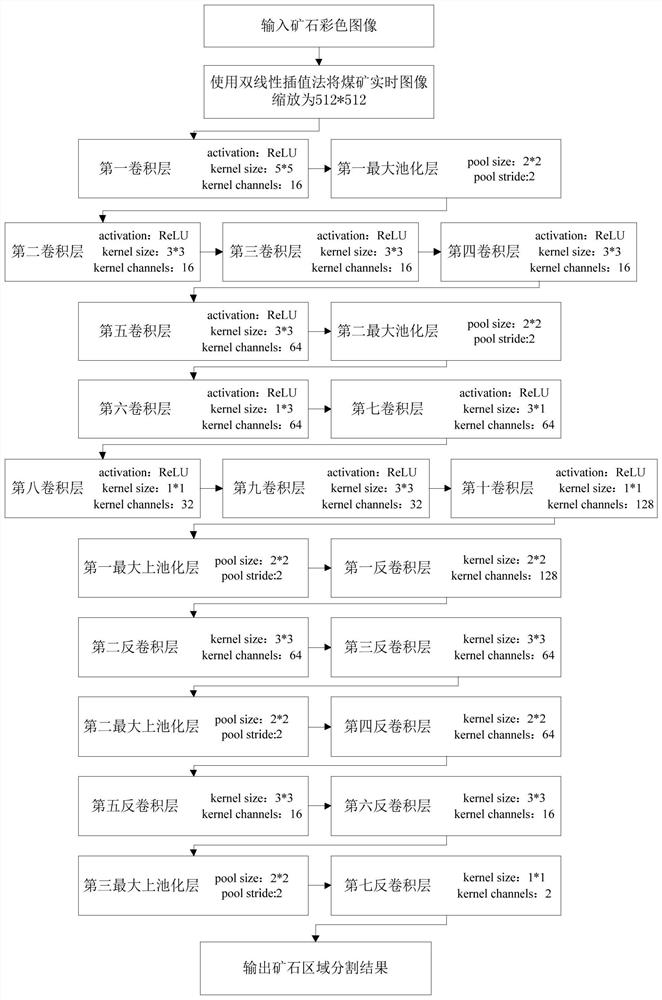

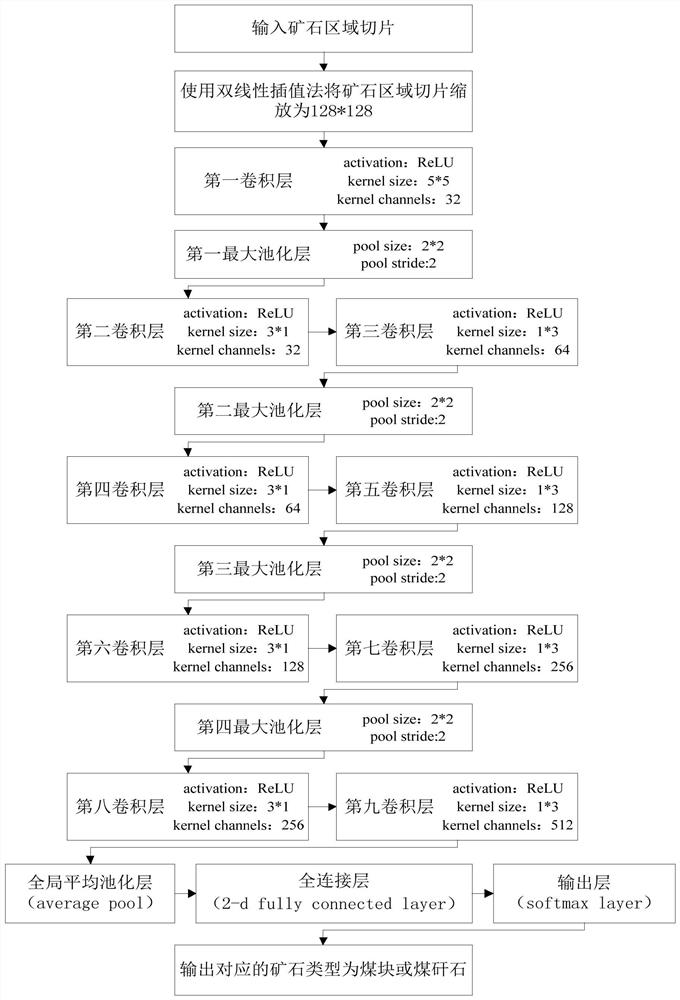

[0040] 2. Input the ore color image into the ore segmentation convolutional neural network for segmentation to obtain the ore area segmentation result, and the ore area segmentation result identifies the area where each ore in the ore sorting production line is located. The processing of the ore color image by the ore segmentation convolutional neural network is as follows:

[0041] First, a bilinear interpolation method is used to scale the ore color image to obtain a size-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com