Composition, preparation method and application thereof in heating material

A composition and slurry technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of long production cycle, large settling square resistance, difficulty in taking into account good stability and efficient preparation process, etc. content, shorten the production cycle, the effect of good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

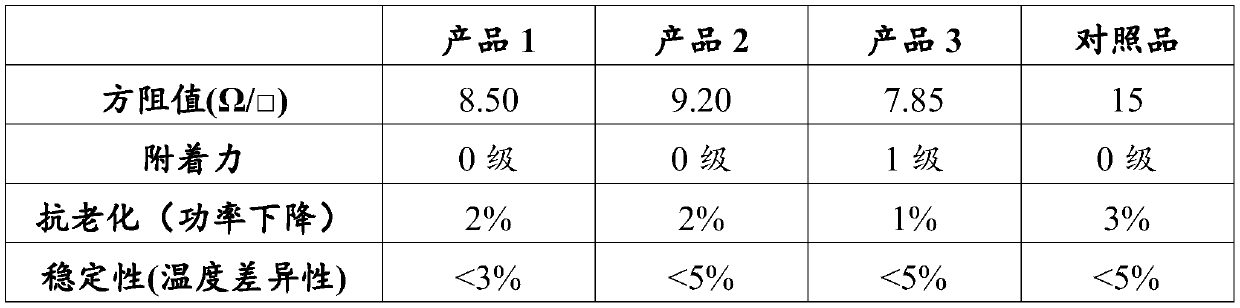

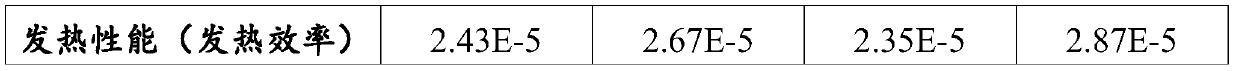

Embodiment 1

[0034] This embodiment is a specific embodiment for preparing the graphene heating material product 1.

[0035] Step 1, the preparation of graphene slurry 1:

[0036] S1. After mixing 3Kg of dispersant dipropylene glycol butyl ether and 100L of deionized water, disperse at a speed of 2000-3500r / min for 60-150min to obtain the first product 1;

[0037] S2. After the first product 1 is mixed with 10Kg of expanded graphite and 1Kg of dispersant povidone K30, ultrasonication is performed for 4-6 hours to obtain the second product 1;

[0038] S3. After mixing the second product 1 with a dispersant (2Kg acrylic block copolymer), homogenize for 2-4 hours to obtain the third product 1;

[0039] S4. After the third product is mixed with 100Kg graphene powder, the graphene slurry 1 is obtained by ultrasonication for 1 hour.

[0040] Step 2, preparation of water-based viscous resin slurry:

[0041] Water-based viscous resin (a mixture of 25Kg polyurethane resin and 25Kg acrylic resin)...

Embodiment 2

[0046] This embodiment is a specific embodiment for preparing the graphene heating material product 2.

[0047] Step 1, the preparation of graphene slurry 2:

[0048] S1. After mixing 0.3Kg dispersant dipropylene glycol butyl ether and 100L deionized water, disperse for 60-150min at a speed of 2000-3500r / min, and obtain the first product 2;

[0049] S2. After mixing the first product 2 with 40Kg of expanded graphite and 0.3Kg of the dispersant povidone K30, ultrasonication was performed for 4-6 hours to obtain the second product 2;

[0050] S3. After mixing the second product 2 with a dispersant (a mixture of 0.1Kg dipropylene glycol butyl ether and 0.2Kg povidone K30), homogenize for 2-4 hours to obtain the third product 2;

[0051] S4. After the third product is mixed with 30Kg graphene powder, the graphene slurry 2 is obtained by ultrasonication for 1 hour.

[0052] Step 2, preparation of water-based viscous resin slurry:

[0053] Water-based viscous resin (a mixture of ...

Embodiment 3

[0058] This embodiment is a specific embodiment for preparing the graphene heating material product 3.

[0059] Step 1, the preparation of graphene slurry 3:

[0060] S1. After mixing 2Kg of dispersant dipropylene glycol butyl ether and 100L of deionized water, disperse at a speed of 2000-3500r / min for 60-150min to obtain the first product 3;

[0061] S2. After mixing the first product 3 with 100Kg of expanded graphite and 4Kg of the dispersant povidone K30, ultrasonication was performed for 4-6 hours to obtain the second product 3;

[0062] S3. After mixing the second product 3 with a dispersant (a mixture of 1Kg dibutyl adipate and 2Kg dipropylene glycol methyl ether acetate), homogenize for 2 to 4 hours to obtain the third product 3;

[0063] S4. After the third product is mixed with 60Kg graphene powder, the graphene slurry 3 is obtained by ultrasonication for 1 hour.

[0064] Step 2, preparation of water-based viscous resin slurry:

[0065] Mix water-based viscous resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com