Heat insulation support of steam manifold

A separate cylinder and temperature insulation technology, which is applied in the direction of steam separation device, boiler support/positioning device, etc., can solve the problems of temperature loss, energy loss, insufficient energy saving and environmental protection of the separate cylinder, and achieve good temperature insulation performance and prevent heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

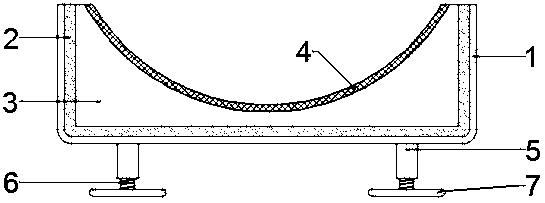

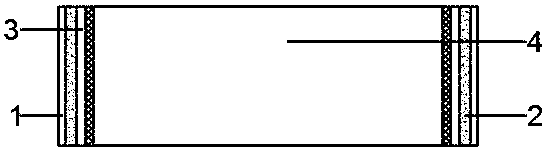

[0018] combine figure 1 and figure 2 , the sub-cylinder temperature-insulating support includes a plate-shaped supporting plate 1 with a U-shaped cross section, and two circular tubular threaded pipes 5 are vertically arranged at the bottom of the supporting plate 1, and threaded rods that are threaded with each other are provided in the two threaded pipes 5 6. The bottom of the two threaded rods 6 is vertically provided with a flat base 7, the inner wall of the supporting plate 1 is provided with a layer of heat insulation layer 2, the inner wall of the temperature insulation layer 2 is provided with a temperature insulation concave frame 3, and the center of the top of the temperature insulation concave frame 3 An arc-shaped groove is provided, and a layer of wear-increasing pad 4 is arranged in the arc-shaped groove on the top of the temperature-insulating concave frame 3 .

[0019] Both the supporting plate 1 and the threaded pipe 5 are made of aluminum alloy, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com